Storage goods updating method and device and logistics system

A technology for goods and warehousing, which is applied in the fields of logistics, instruments, and data processing applications. It can solve problems such as difficulties in loading front warehouses, affecting warehousing and picking, and more time and energy. It achieves large site space, improved efficiency, and The effect of low manpower and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

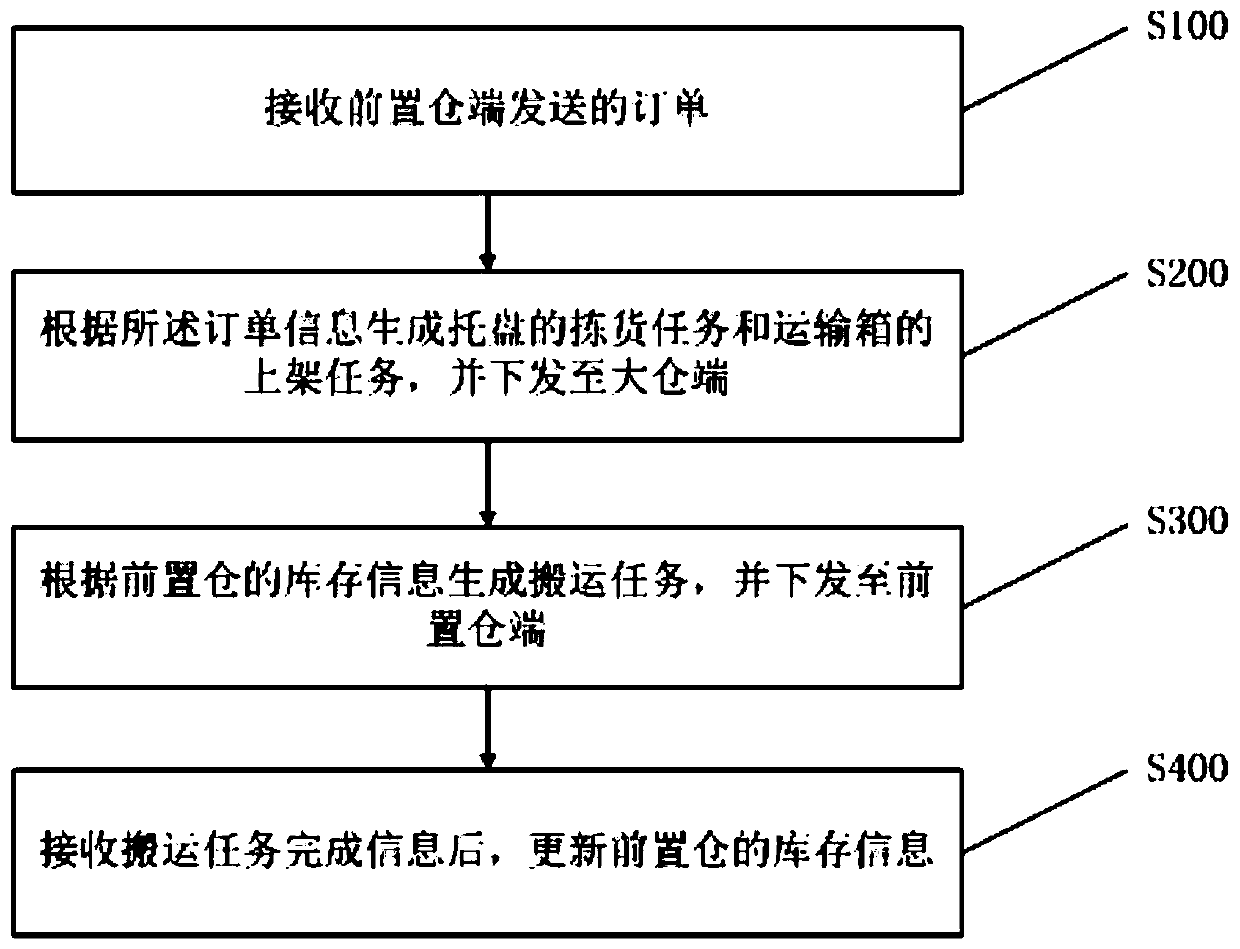

[0047] A method for updating warehoused goods in this embodiment, such as figure 1 shown, including the following steps:

[0048] Step S100, receiving the order sent by the front warehouse.

[0049]Specifically, the employees of the front warehouse generate orders through the front warehouse terminal and upload them to WMS (Warehouse Management System, Warehouse Management System), and the WMS receives the orders sent by the front warehouse terminal. Information, product information that needs to be replenished, and information on large warehouses that provide replenished goods, etc. It is worth noting that the front warehouse here can be the entrance of the front warehouse of the WMS system, or it can be other software that can be connected to the WMS separately set in the front warehouse.

[0050] Step S200, generate a pallet picking task and a shelf task for each transport box on the pallet according to the order information and the warehouse's inventory information, and ...

Embodiment 2

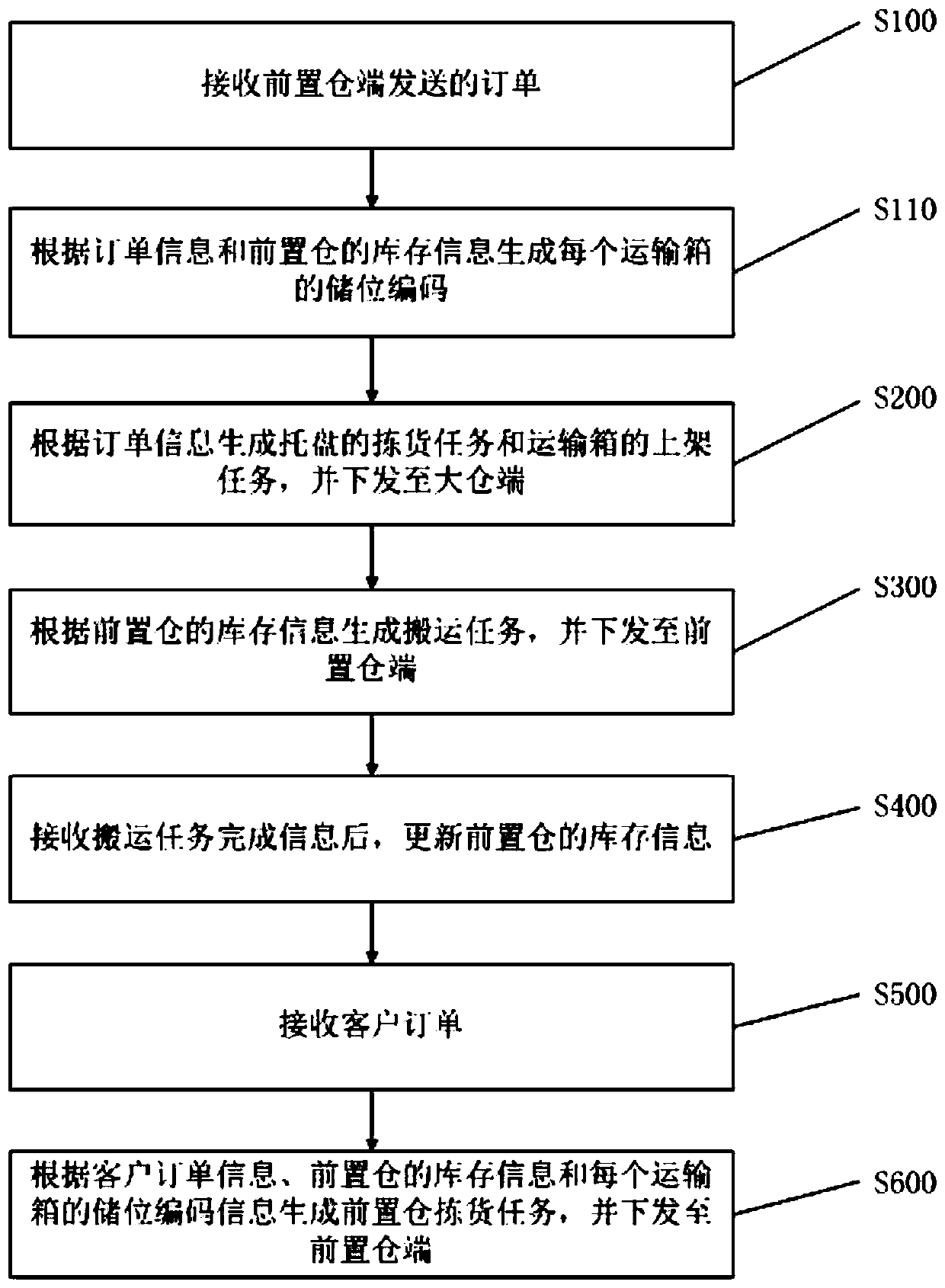

[0058] The difference between this embodiment and Embodiment 1 is: in this embodiment, if figure 2 As shown, step S200, before generating the picking task of the pallet and the putting task of each transport box on the pallet according to the order information, further includes:

[0059] Step S110, generating a storage location code for each transport box on the pallet according to the order information and the inventory information of the front warehouse.

[0060] Specifically, in order to facilitate the subsequent pick-and-ship of the front warehouse to the customer, the storage location code of each transport box on the pallet is generated according to the order information and the inventory information of the front warehouse, and the information of the storage location code includes the corresponding Commodity information in the transport box and the storage slot number of the location where the transport box is placed in the front warehouse. The storage location code is...

Embodiment 3

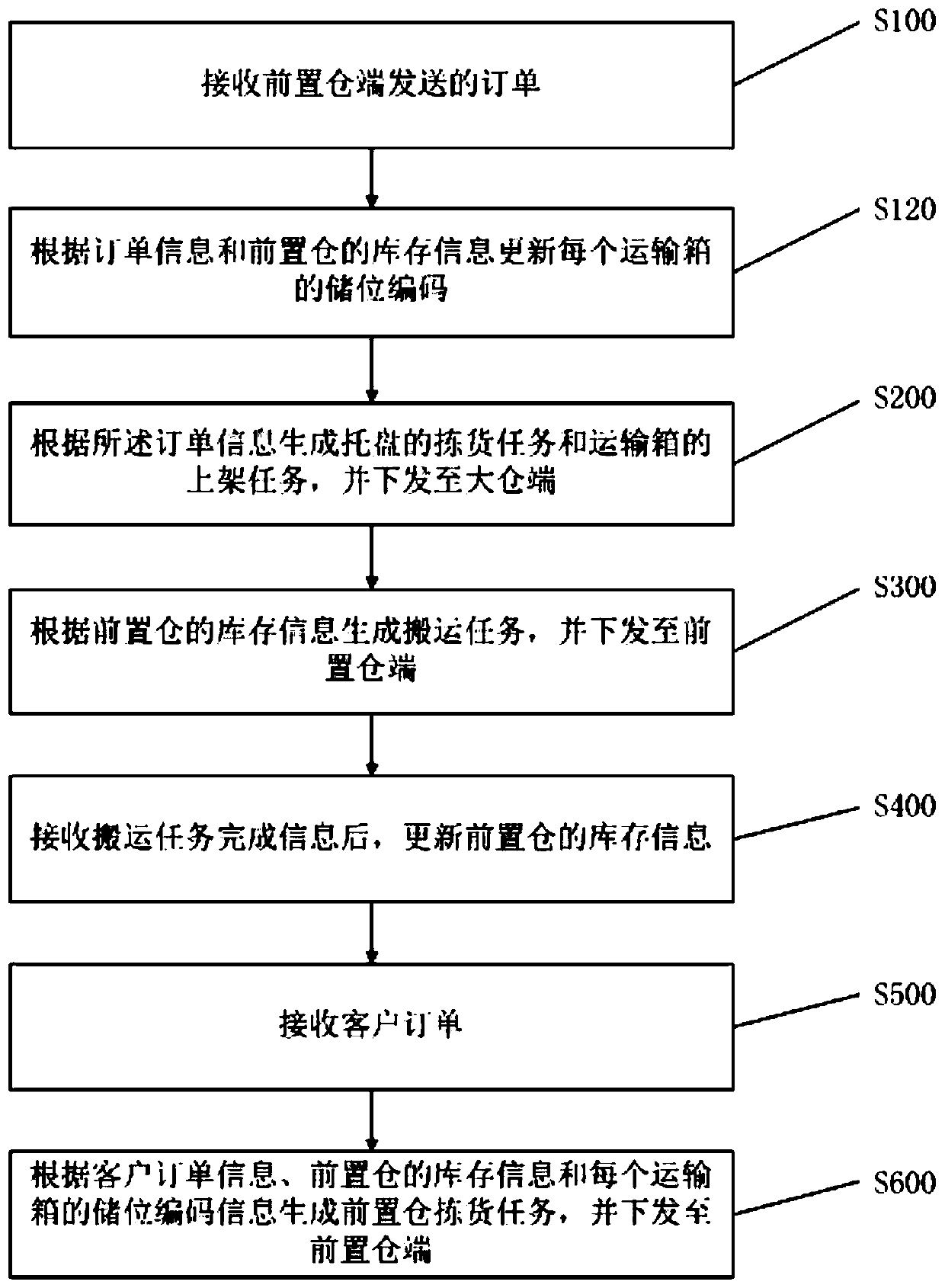

[0067] The difference between the present embodiment and the second embodiment is that: image 3 As shown, step S200, before generating the picking task of the pallet and the putting task of each transport box on the pallet according to the order information, further includes:

[0068] Step S120, updating the storage position code of each transport box on the pallet according to the order information and the inventory information of the front warehouse.

[0069] Specifically, the paper-based storage code in Embodiment 2 is replaced with a storage code in the form of an electronic label. The storage code is always placed in front of the transport box, and each time the transport box is used, the WMS updates the transport box according to the order. The content of the storage location code is enough, which can save the time and manpower of printing paper labels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com