Plastic rivet

A technology of plastic rivets and nail sleeves, applied in the direction of rivets, screws, threaded fasteners, etc., can solve the problems of plastic parts deformation, inconvenient use, etc., and achieve the effect of not easy to detach, easy to manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

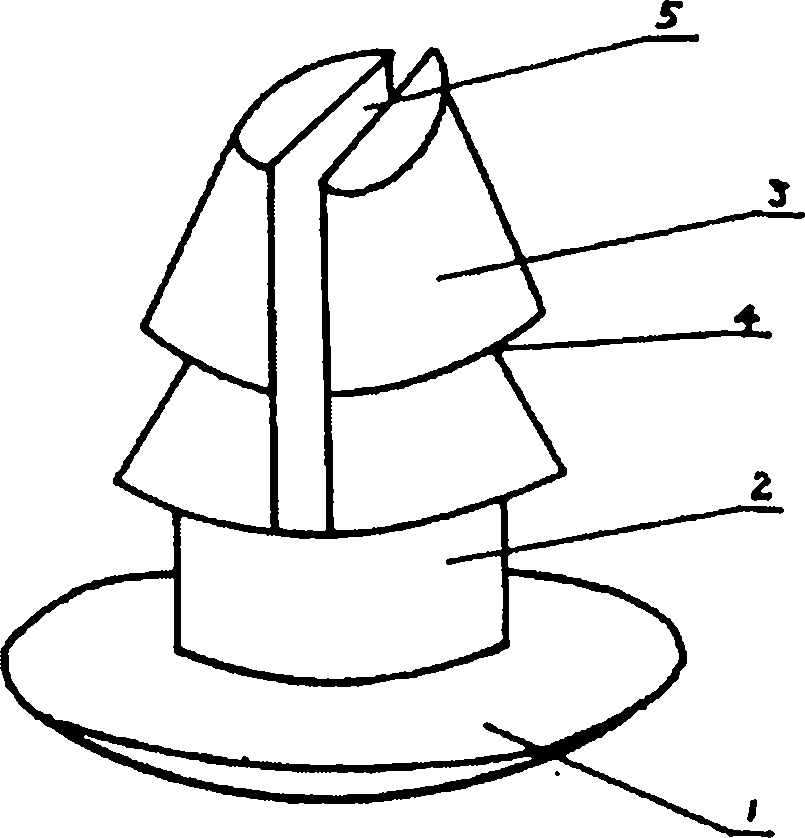

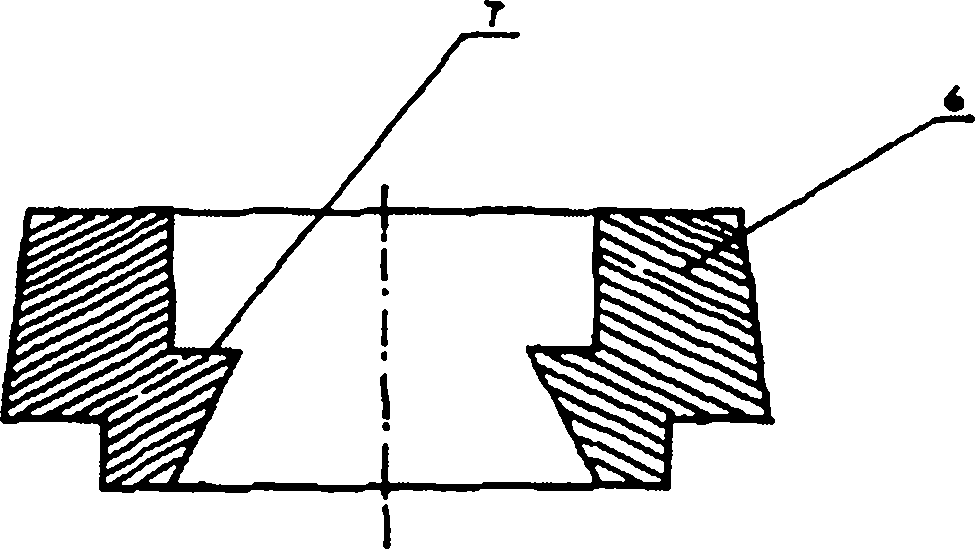

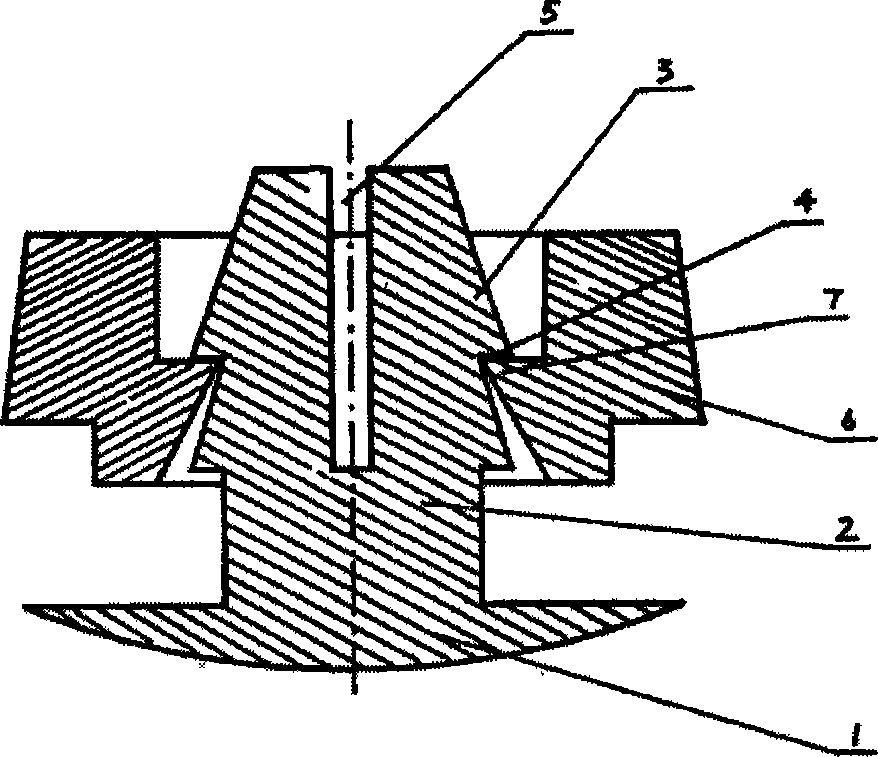

[0010] figure 1 The nail wire has a nail cap 1 and a nail shank 2, two tapered protrusions 3 of the nail shank form an annular depression 4, and a slit 5 is in-line, located in the middle of the nail shank front end, and the slit can also be made into a cross shape. figure 2 There is an annular protrusion 7 on the inner wall of the circular hole in the center of the nail sleeve 6 . When used as image 3 As shown, due to the certain elasticity of the plastic, when the nail rod is pressed into the nail sleeve, the two sides of the slit of the nail rod are compressed toward the middle, and the annular protrusion 7 of the nail sleeve snaps into the annular depression 3 of the nail rod. . Since the nail cap and the nail sleeve maintain a fixed distance, the connected workpieces can maintain a certain degree of looseness, and the workpieces can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com