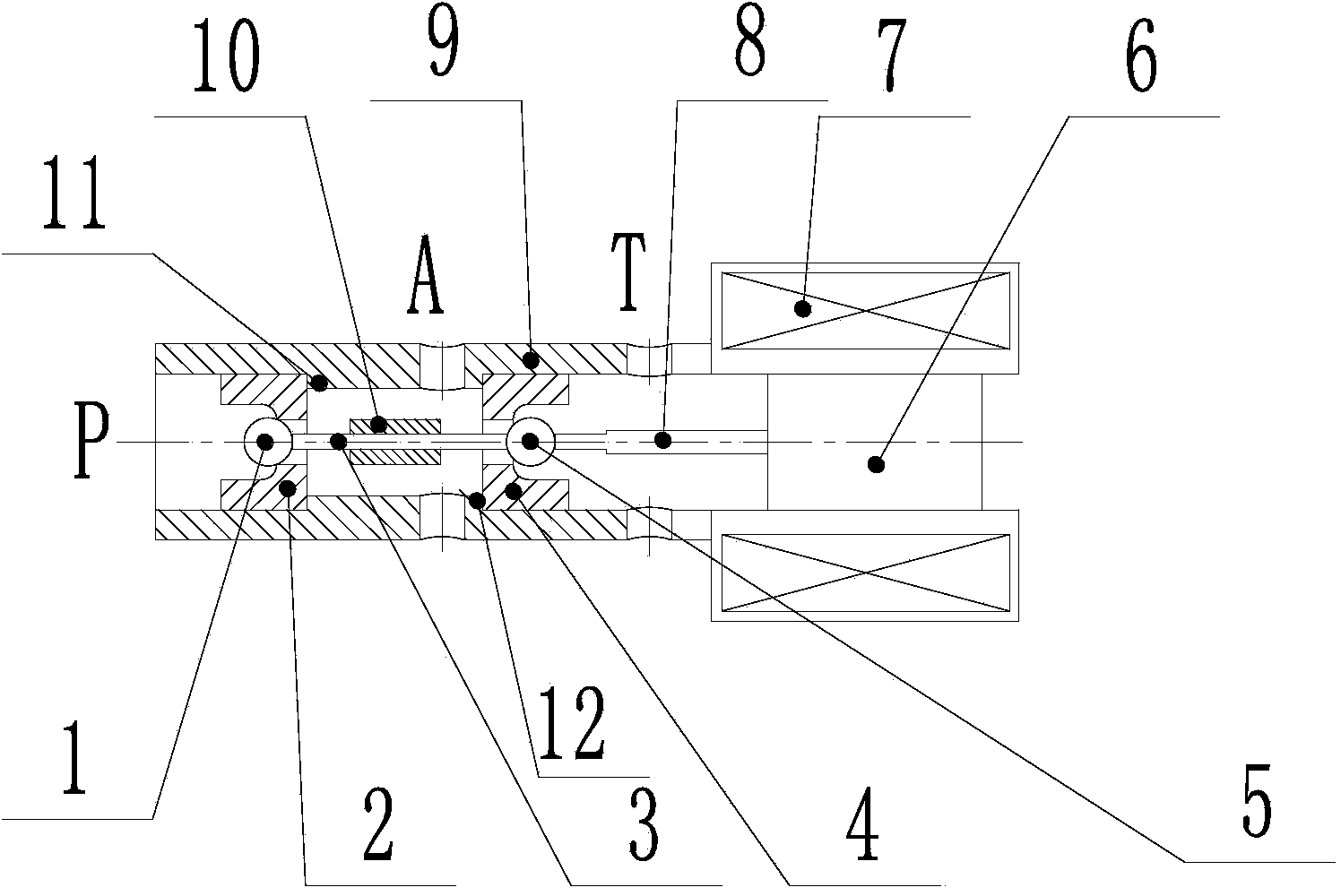

High-pressure big-thrust two-position three-way ball valve structure

A two-way, three-way, high-thrust technology, applied to multi-way valves, valve details, valve devices, etc., can solve problems such as the inability to take into account high-frequency response and large flow, and difficulty in keeping the ball seat still

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

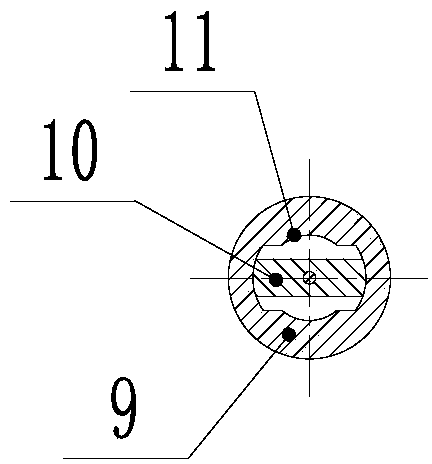

[0020] refer to figure 1 and figure 2 , a high-pressure and high-thrust two-position three-way ball valve structure, including a valve sleeve 9, a left steel ball seat 2, a push pin seat 10, a right steel ball seat 4 and an armature 6 are arranged inside the valve sleeve 9, and the outer side of the armature 6 Arrange the electromagnetic coil 7 for controlling the action of the armature, the armature 6 is connected with the push rod 8, the end of the push rod 8 is connected with the right end of the right steel ball 5, and the right steel ball 5 is located on the right steel ball seat 4 In the through hole, the 5 left ends of the right steel ball are connected with the right end of the push pin 3, the push pin 3 is installed on the push pin seat 10, the left end of the push pin 3 is connected with the left steel ball 1, and the left steel ball 1 Located in the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com