Three-dimensional sensitive structure element with multi-curved-surface fusion and vibratory gyroscope comprising same

A multi-surface fusion, sensitive structure technology, applied in the field of three-dimensional multi-surface fusion sensitive structure vibrating gyroscope, can solve the problems of low quality factor, poor anti-overload capability, etc., to improve the signal-to-noise ratio, high anti-overload capability, avoid stress effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

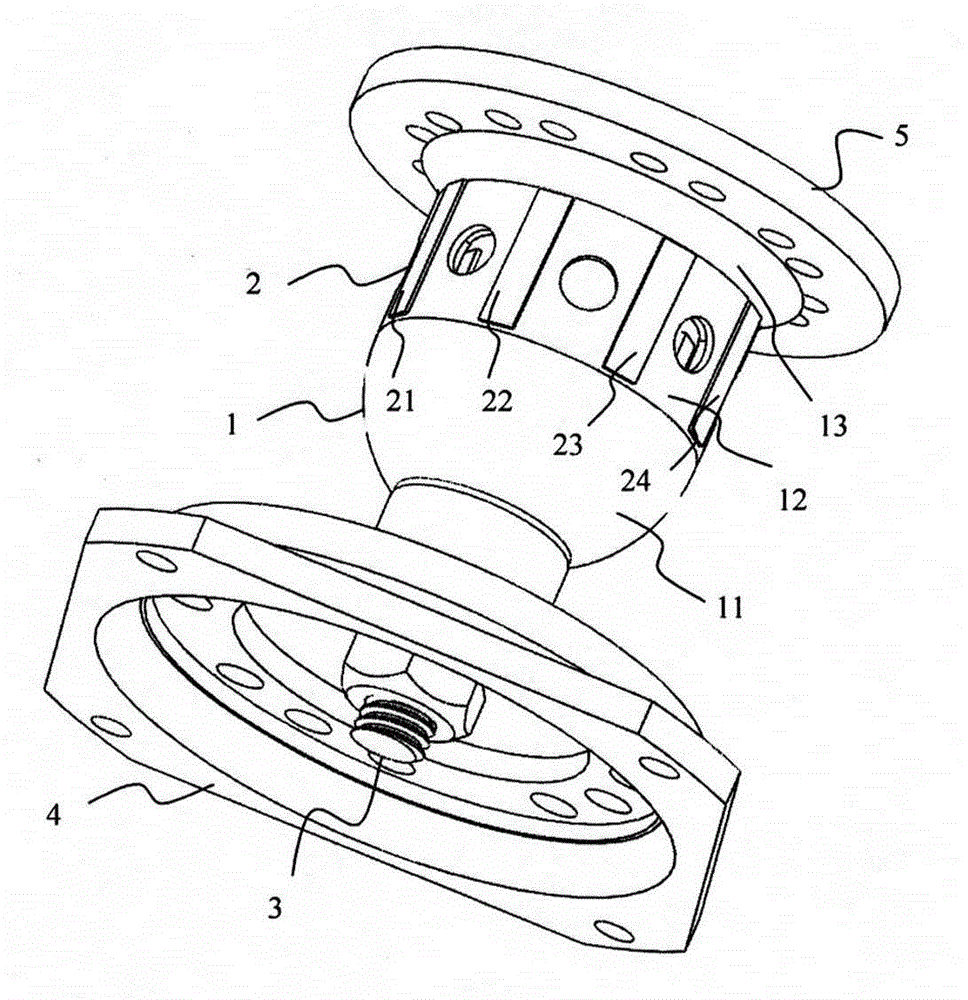

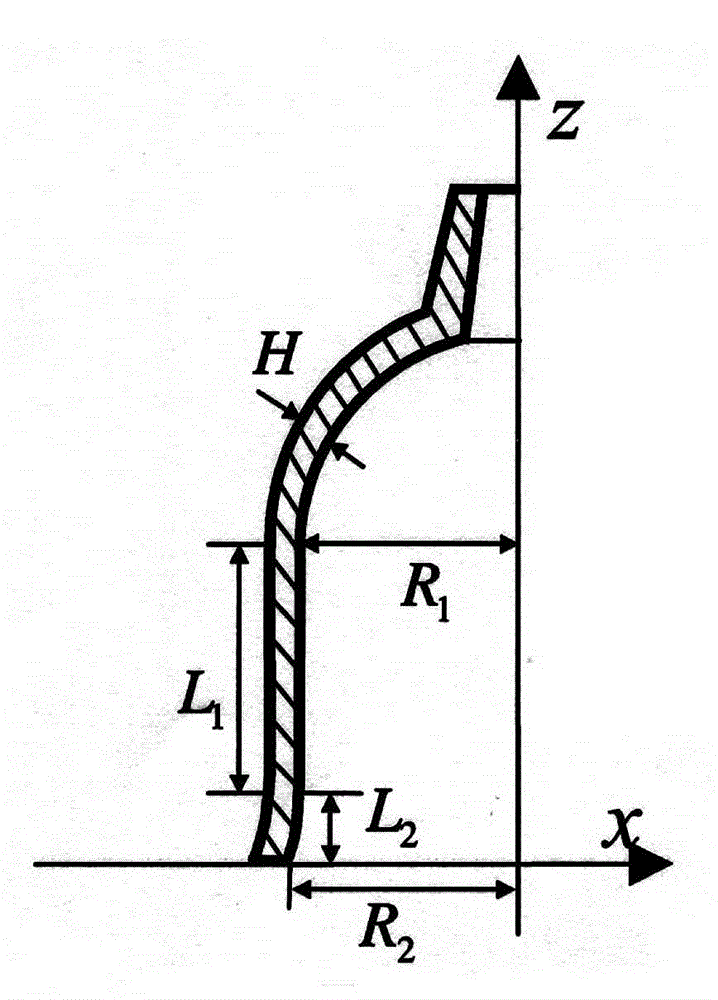

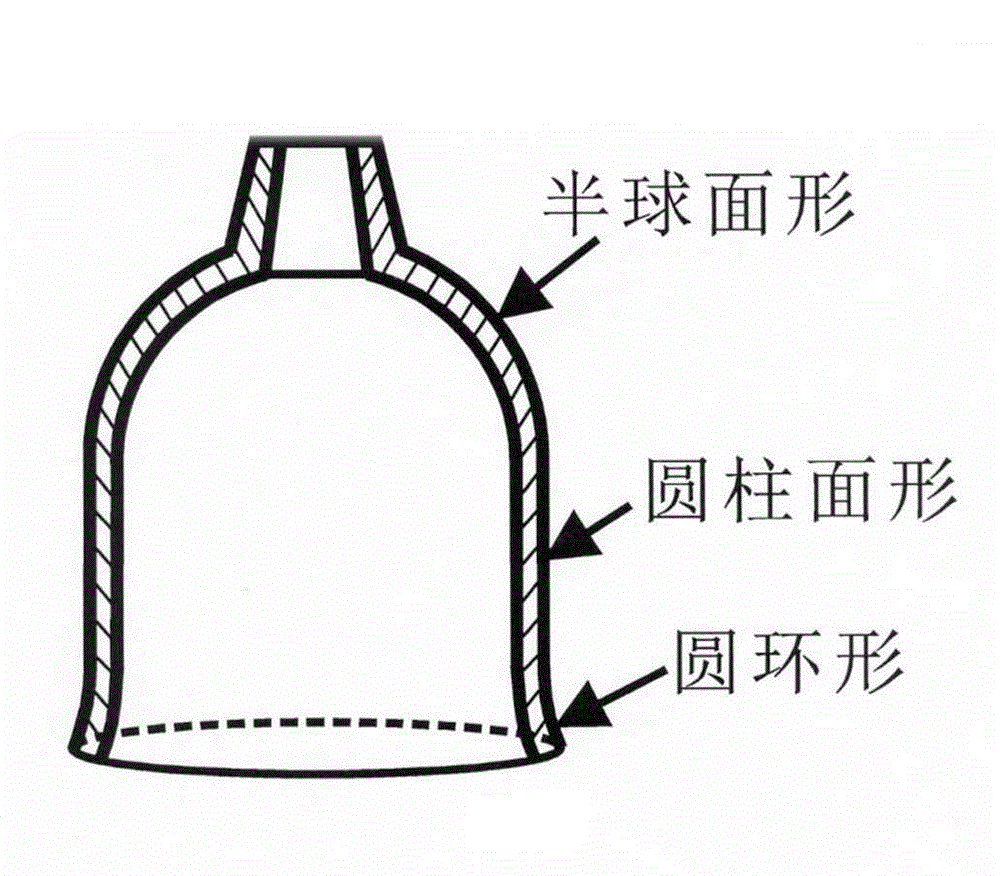

[0033] Such as figure 1 As shown, the core part of the three-dimensional multi-curved surface fusion sensitive structural element of the present invention includes a three-dimensional sensitive structure (1), a piezoelectric electrode (2), a supporting axis (3), a base (4) and a casing (5). According to the characteristics of the actual use environment, the three-dimensional sensitive structure (1) is integrally processed with a constant elastic alloy material, and its main material properties are: density ρ =8170 g / cm 3 ,Poisson's ratio mu =0.3, Young's modulus E =196.76Gpa, tensile strength σ b =500Mpa, yield strength σ s =275MPa. further, such as figure 2 As shown, the optimized parameters of the three-dimensional sensitive structure (1) obtained after the finite element simulation design are: the radius of the hemispherical surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com