A Test Bench for Measuring Small Hole Discharge Coefficient under Rotating Condition

A flow coefficient and test bench technology, applied in the field of test benches, can solve the problem that the measurement of the flow coefficient of the rotating small hole has little reference value, the error of the experimental result is too large to accurately measure the flow coefficient of the rotating small hole, and the grate and rotation cannot be guaranteed. Disk gap consistency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

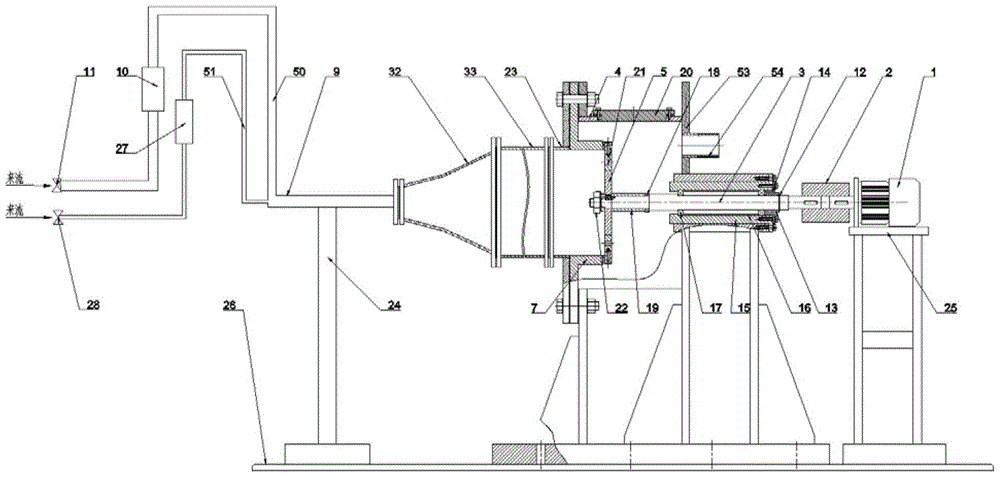

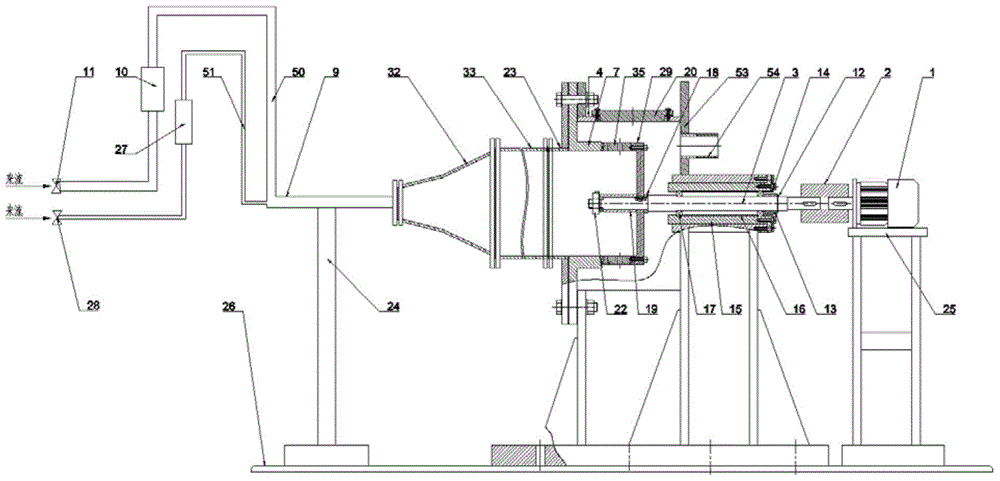

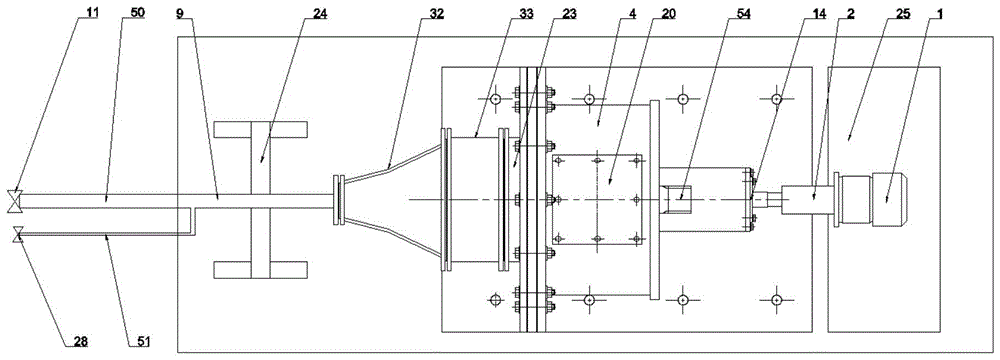

[0040] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] see figure 1 , 2, the present invention comprises successively connected intake section, mixing section, expansion section, stabilizing section, test section and main shaft and drive motor thereof, and test bench is fixed on the ground by support, is characterized in that:

[0042] The air intake section includes a thick and a thin double-pipe air intake (DN80 and DN50 are desirable), and the two air intake pipes 50 and 51 are respectively provided with air intake valves 11 and 28, and behind the two valves are respectively provided with respective channel flowmeters 10, 27 and thermocouple (not shown). The channel flowmeters 10 and 27 are used to measure the flow of gas entering the casing through the pipeline. The channel flowmeter is arranged near the valve of the pipeline and connected with the pipeline through a flange. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com