Design method of horizontal pull rod of high furnace bustle pipe

A technology for a hot air enclosure and a design method, which can be used in computing, special data processing applications, instruments, etc., can solve problems such as material waste and cost, and achieve the effect of reducing costs and optimizing materials and structural dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

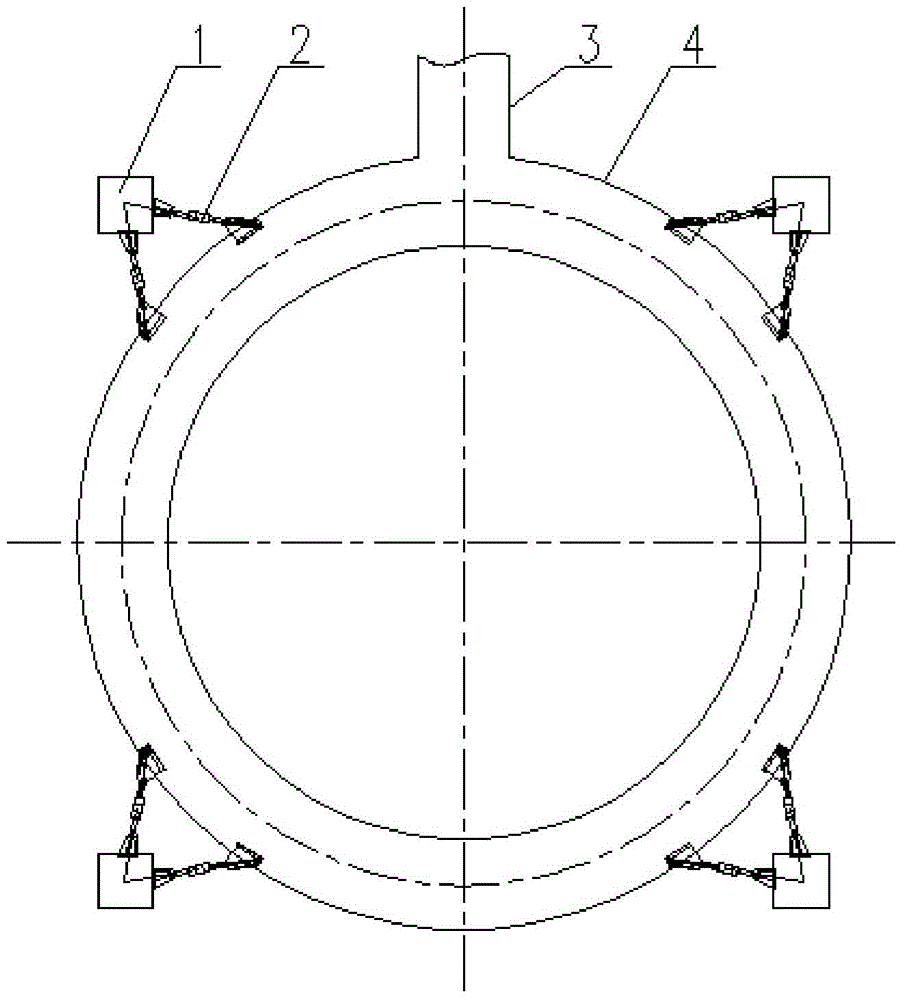

[0022] The present invention provides a design method for the horizontal tie rod of the blast furnace hot blast surrounding pipe, comprising the following steps: Step 1, calculating the force generated by the wind pressure of the hot blast main pipe 3 on the tie rod 2 and calculating the force generated by the deformation of the hot blast surrounding pipe 4 on the tie rod 2 Force; step 2, calculate the maximum force on a single tie rod 2 according to the calculation result in step 1; step 3, determine the diameter of the tie rod 2 according to the maximum force on a single tie rod 2.

[0023] Through the design method of the horizontal tie rod of the blast furnace hot blast surrounding pipe of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com