A soldering pad for a six-pin 5050 led lamp

A six-pin, pad technology, applied to the pad field of six-pin 5050 LED lamp, can solve the problem of low heat dissipation efficiency, achieve the effect of improving heat dissipation efficiency, avoiding tin connection, and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

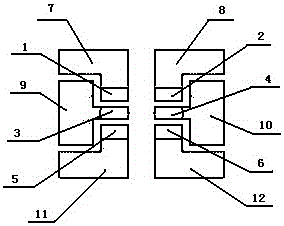

[0028] A welding pad for a six-pin 5050 LED lamp, comprising first to sixth pin pads, and first to sixth copper skins correspondingly connected to the first to sixth pin pads, the first pin soldering pads Plate 1 and the second pin pad 2 form a group, the third pin pad 3 and the fourth pin pad 4 form a group, the fifth pin pad 5 and the sixth pin pad 6 form a group Group, three groups of pads are arranged in turn, wherein, the centers of the first pin pad 1, the third pin pad 3, and the fifth pin pad 5 are located on the same straight line, and the centers of the second pin pad 2, The centers of the fourth pin pad 4 and the sixth pin pad 6 are located on the same straight line, and the two straight lines are parallel to each other, and the areas of the first to sixth copper skins are the same, wherein the first copper skin 7, the sixth copper skin The second copper skin 8, the fifth copper skin 11, and the sixth copper skin 12 have the same shape, the third copper skin 9 and t...

specific Embodiment 2

[0030]A welding pad for a six-pin 5050 LED lamp, comprising first to sixth pin pads, and first to sixth copper skins correspondingly connected to the first to sixth pin pads, the first pin soldering pads Plate 1 and the second pin pad 2 form a group, the third pin pad 3 and the fourth pin pad 4 form a group, the fifth pin pad 5 and the sixth pin pad 6 form a group Group, three groups of pads are arranged in turn, wherein, the centers of the first pin pad 1, the third pin pad 3, and the fifth pin pad 5 are located on the same straight line, and the centers of the second pin pad 2, The centers of the fourth pin pad 4 and the sixth pin pad 6 are located on the same straight line, and the two straight lines are parallel to each other, and the areas of the first to sixth copper skins are the same, wherein the first copper skin 7, the sixth copper skin The second copper skin 8, the fifth copper skin 11, and the sixth copper skin 12 have the same shape, the third copper skin 9 and th...

specific Embodiment 3

[0032] A welding pad for a six-pin 5050 LED lamp, comprising first to sixth pin pads, and first to sixth copper skins correspondingly connected to the first to sixth pin pads, the first pin soldering pads Plate 1 and the second pin pad 2 form a group, the third pin pad 3 and the fourth pin pad 4 form a group, the fifth pin pad 5 and the sixth pin pad 6 form a group Group, three groups of pads are arranged in turn, wherein, the centers of the first pin pad 1, the third pin pad 3, and the fifth pin pad 5 are located on the same straight line, and the centers of the second pin pad 2, The centers of the fourth pin pad 4 and the sixth pin pad 6 are located on the same straight line, and the two straight lines are parallel to each other, and the areas of the first to sixth copper skins are the same, wherein the first copper skin 7, the sixth copper skin The second copper skin 8, the fifth copper skin 11, and the sixth copper skin 12 have the same shape, the third copper skin 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com