One-way self-powered net box

A self-powered, cage technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of large longitudinal traction force of wedge-shaped diverter, low level of technical informatization, unbalanced lateral force, etc. high risk, high safety and balanced traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

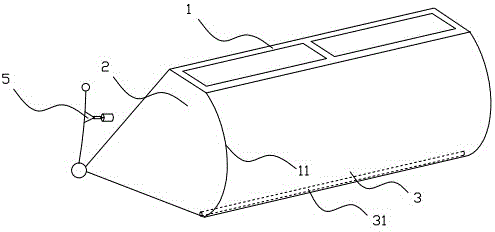

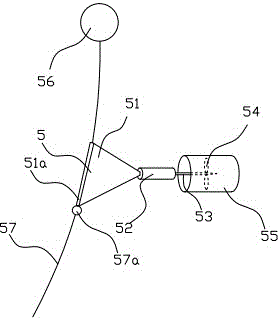

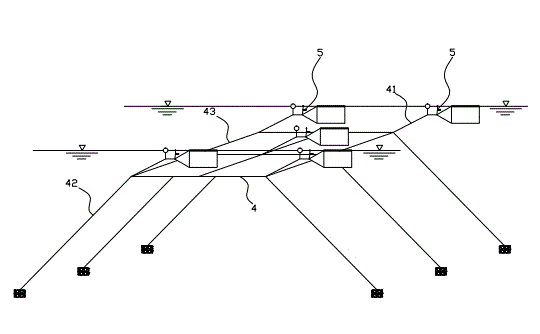

[0021] Example: refer to Figure 1 to Figure 3, a one-way self-power supply cage, including a rectangular floating tube 1 located at the top of the cage, wherein: below the floating tube 1 is connected a cylindrical cage 3 whose axis is a horizontal direction; one end of the cylindrical cage 3 has a ring-shaped reinforcement truss 11, and the other side of the reinforced truss 11 is connected with a diverter 2 with a conical steel pipe truss structure; the bottom of the cylindrical cage 3 is provided with an HDPE immersed pipe 31 along the direction parallel to the axis; HDPE immersed pipe 31 is filled with iron sand; the shunt 2 is also connected with a floating power supply module 5 that can monitor the surface flow velocity. The application of the conical diverter 2 has better stability for water body fluctuations than the prior art, so it can effectively achieve the instantaneous tension extreme value of the mooring rope system, effectively reduce the risk of anchoring, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com