Rat hole blaster

A blaster, rat hole technology, applied in the direction of killing equipment, poison, hunting equipment, etc., can solve the problems of easily destroying the ecological balance, difficult to implement, and high cost, and achieves easy large-scale implementation, outstanding substantive features, and stable working performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

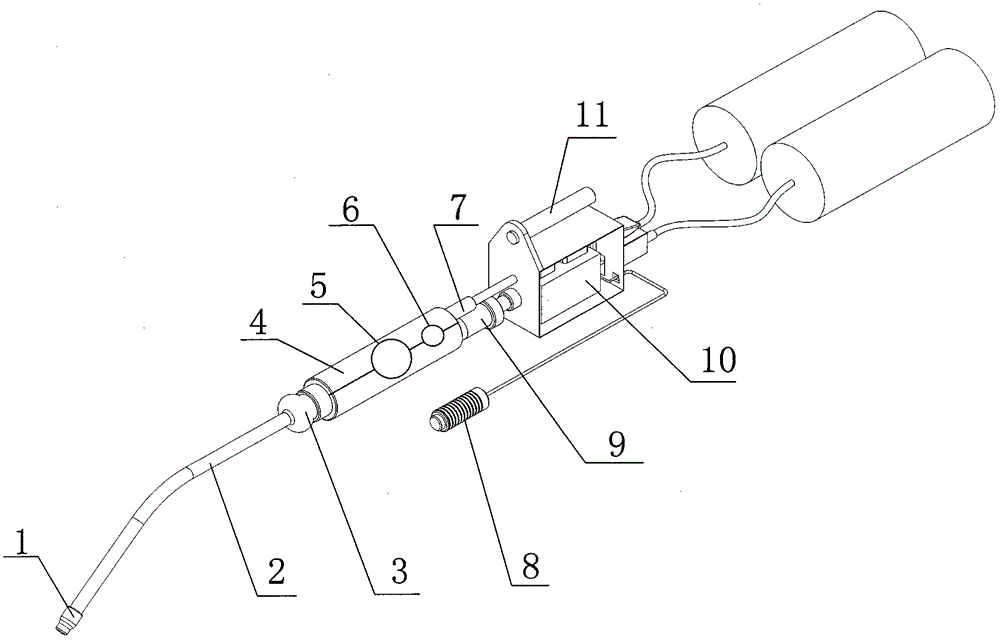

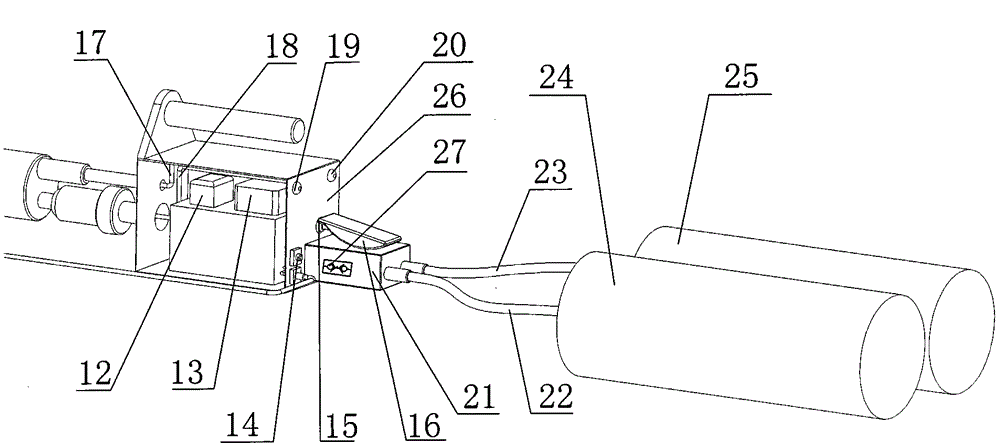

[0018] see figure 1 and figure 2 Shown mouse hole blaster comprises fuel tank, gas jet pipeline 4 and blasting controller 26, and blasting controller 26 is arranged on the pipeline that fuel tank communicates with gas jet pipeline 4; Fuel tank is made up of propane high-pressure gas tank 24 and oxygen high-pressure gas tank 25 components; the front end of the jet pipeline 4 is provided with an extension tube 2, and the extension tube 2 is provided with an ignition head 1; the rear end of the jet pipeline 4 is respectively connected to the sleeve 7 of the oxygen branch circuit and the reset check valve of the propane branch circuit 9 are connected, and are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com