A distributing device for a centrifuge

A technology of distributing device and centrifuge, which is applied in the direction of centrifuge, etc., can solve the problems of low strength of the outer cylinder of the distributing device, the crushing of materials that cannot be agglomerated, and the inability to be centrifugally thrown out by the distributing device, etc., so as to achieve a regular and extended distribution space. The effect of service life and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific examples.

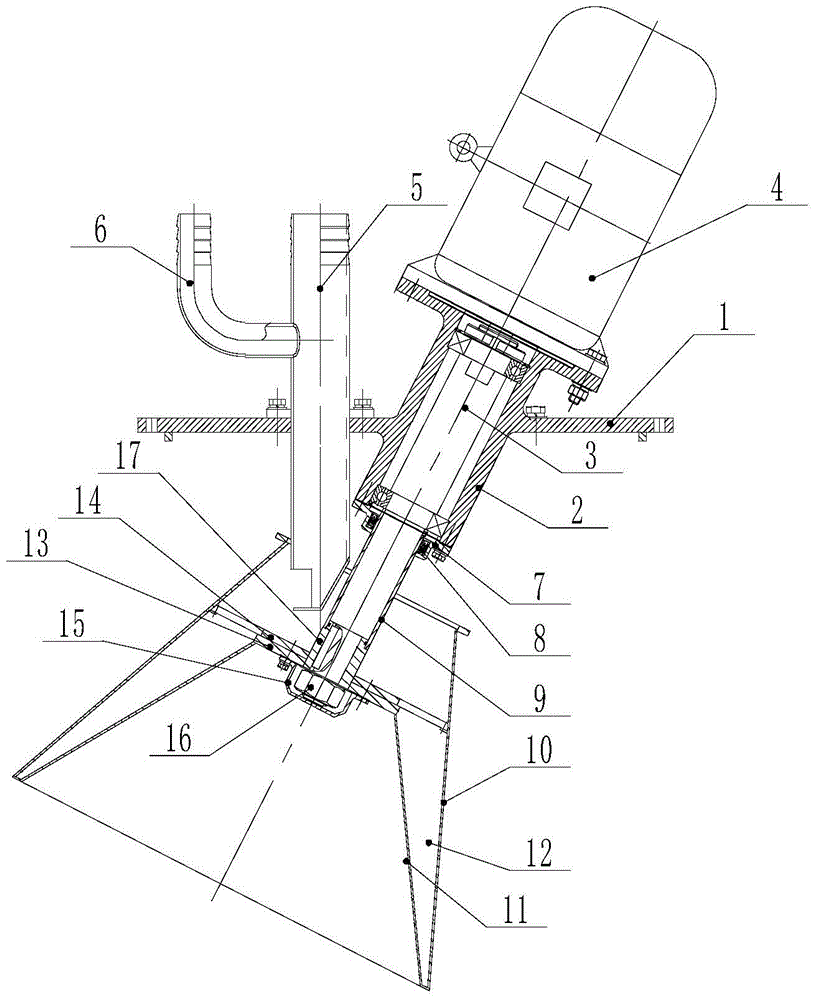

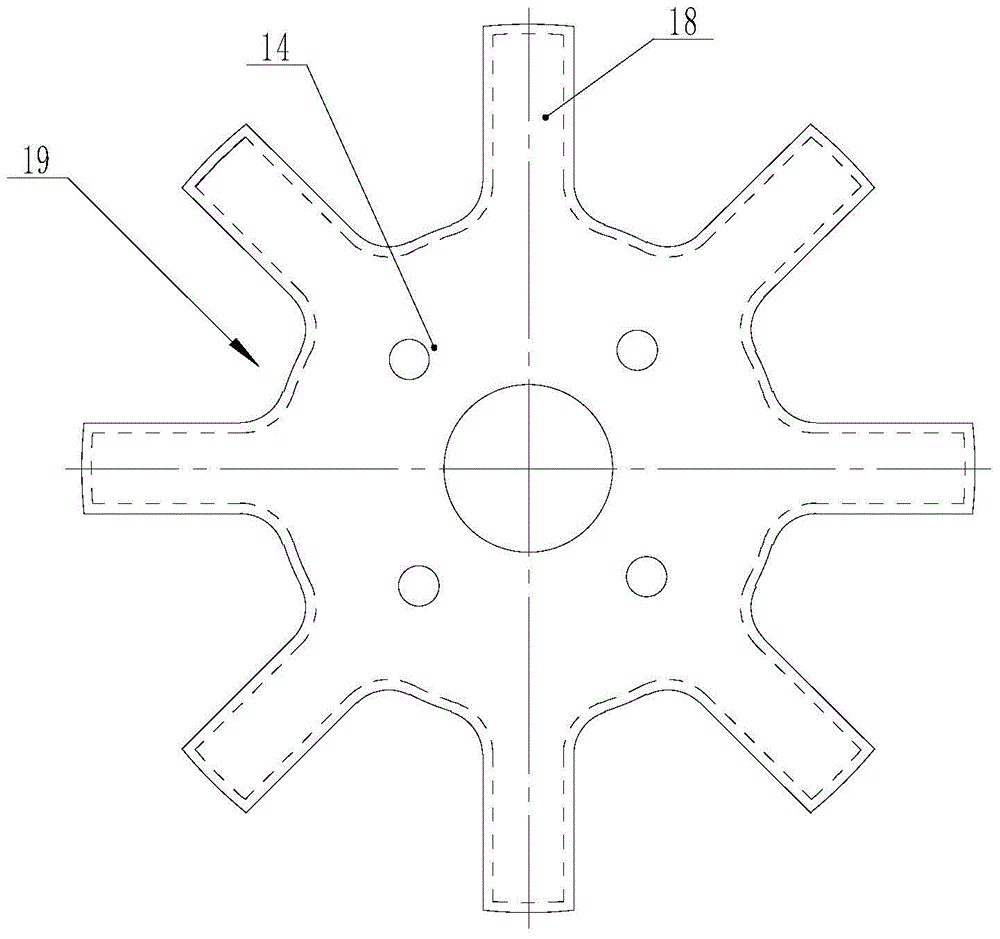

[0019] Such as figure 1 , 2 Shown, a kind of distributing device of centrifuge, comprises the distributing device that is installed on the top cover 1 of centrifuge and is arranged obliquely, is fixed on the feed pipe 5 on centrifuge top cover 1, and the lower end of this feed pipe 5 Extending into the distributor, the feed pipe 5 is vertically arranged, and the upper part of the feed pipe 5 communicates with the washing pipe 6, and the lower end side wall of the feed pipe 5 is provided with an outlet, which is convenient for directly spraying into the cloth space 12 Inside, the distributor is driven and rotated by a motor 4, a motor 4 seat 2 integrated with the top cover 1 is arranged on the top cover 1, and a through shaft hole is provided on the motor 4 seat 2, and the motor 4 is fixed on the motor 4 On the seat 2, the drive shaft 3 connected with the output shaft of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com