Non-platform structure of chip carrier power generator and power generator piping system pre-assembling method

A platform structure and generator technology, which is applied to ship parts, ship construction, transportation and packaging, etc. It can solve the problems of small repair space for generators, inconvenient cleaning and maintenance by crew, messy space, etc., and achieves convenient and convenient cleaning of pipes The effect of maintenance, space tidiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the drawings and embodiments. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

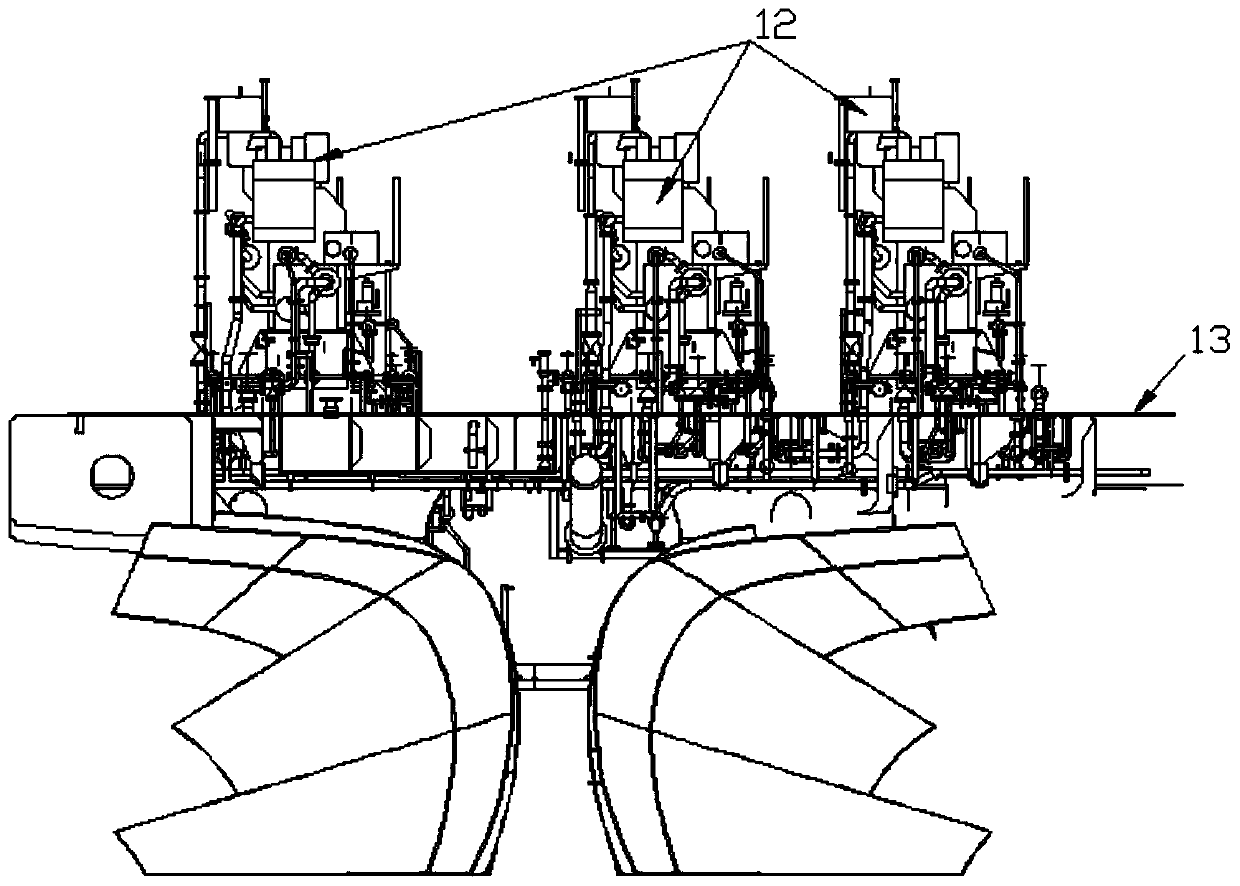

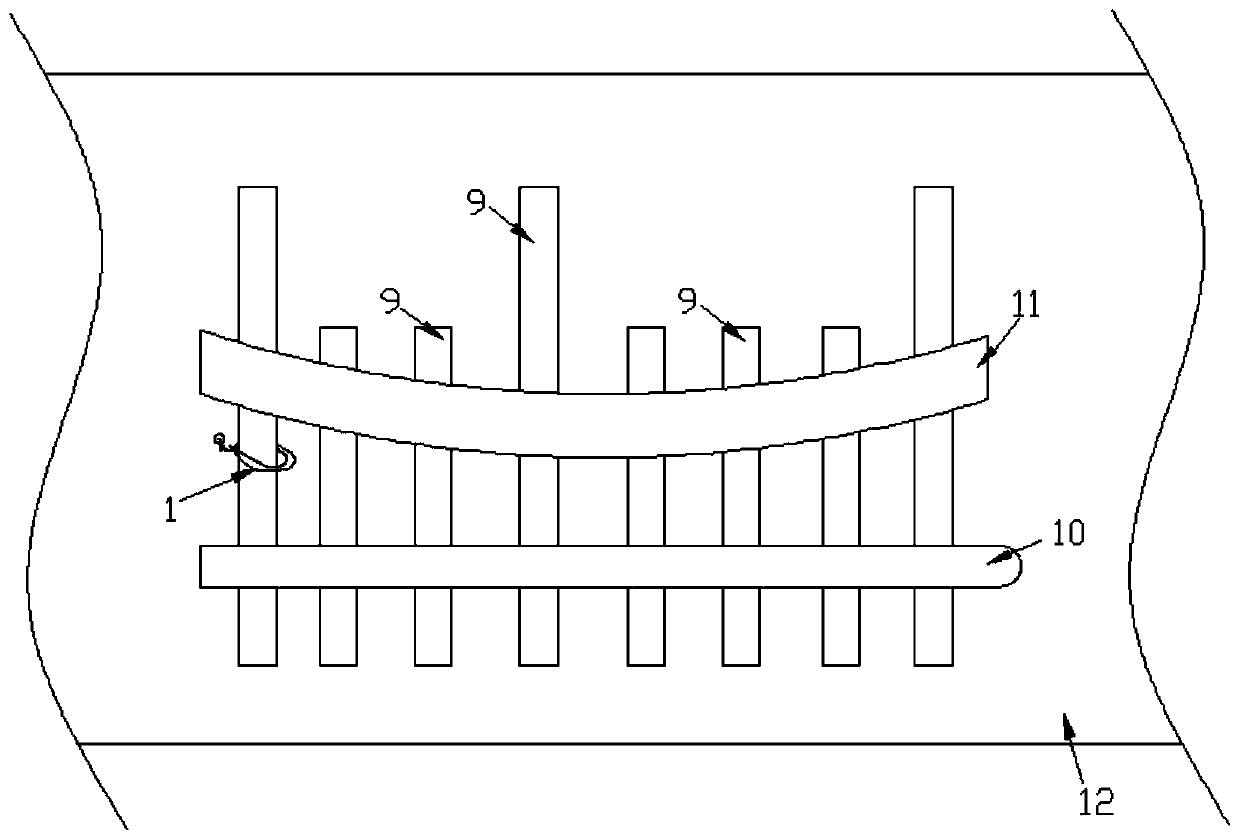

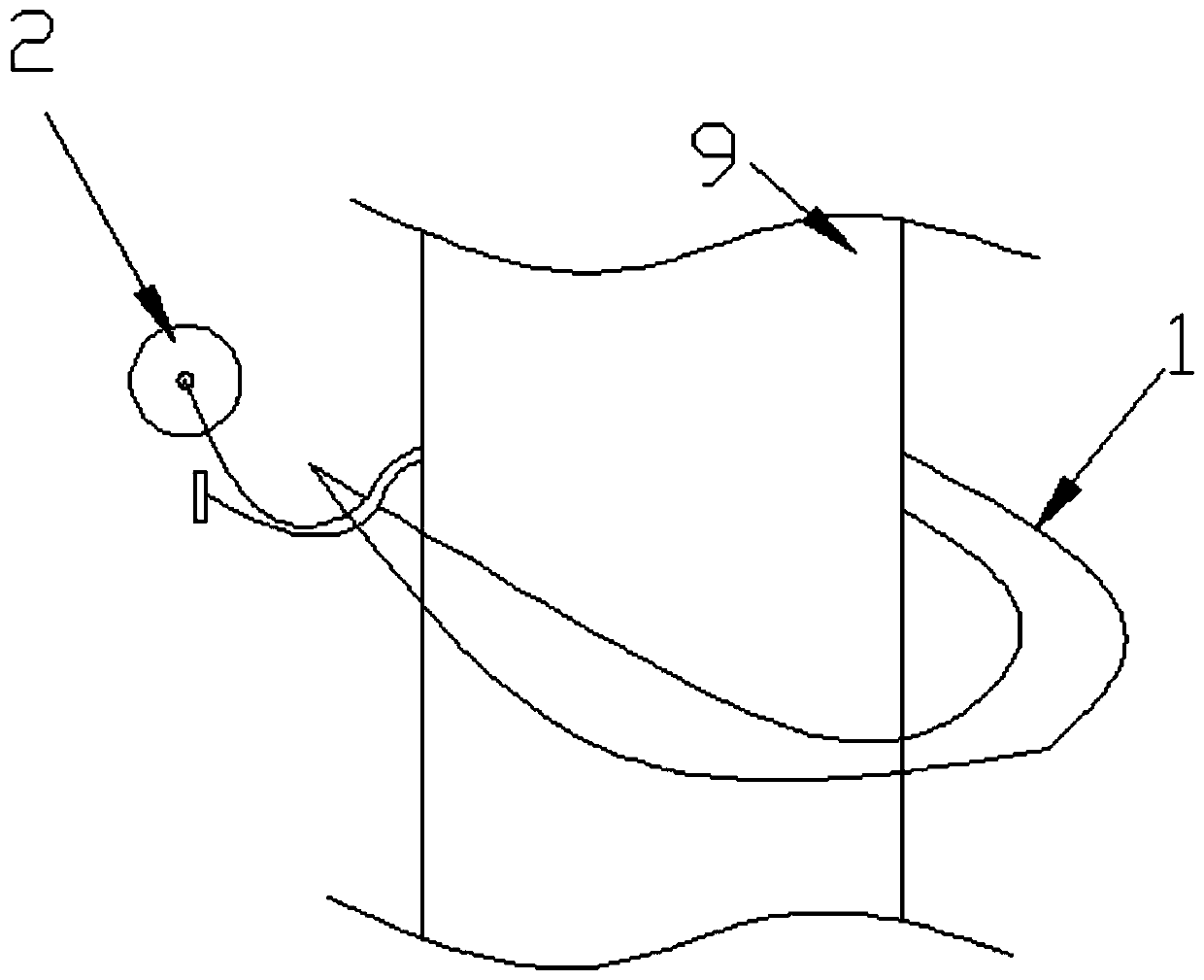

[0023] Figure 1 to Figure 6 As shown (for the sake of illustration, only two specifications of straight pipes are shown in the figure. In reality, there may be straight pipes of various specifications and lengths, but this does not affect the setting of this scheme), the present invention is a wood chip ship power generation The platform-free structure of the generator includes a tightening rope 1 fixedly connected with two rope ends and a suction cup 2 fixedly connected to the tightening rope 1. The tightening rope 1 is wound around the generator 12 and its tube; the platform-free structure also It includes an elastic rubber connector 3, the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com