Slag scrapping machine special for cleaning paint slag in paint spray room

A slag scraper, paint spray booth technology, applied in the direction of spray device, device for coating liquid on the surface, coating, etc., can solve the problems of difficult maintenance, difficult to clean, complex structure, etc., to achieve simple structure, maintenance and repair. Convenient, scientifically designed and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

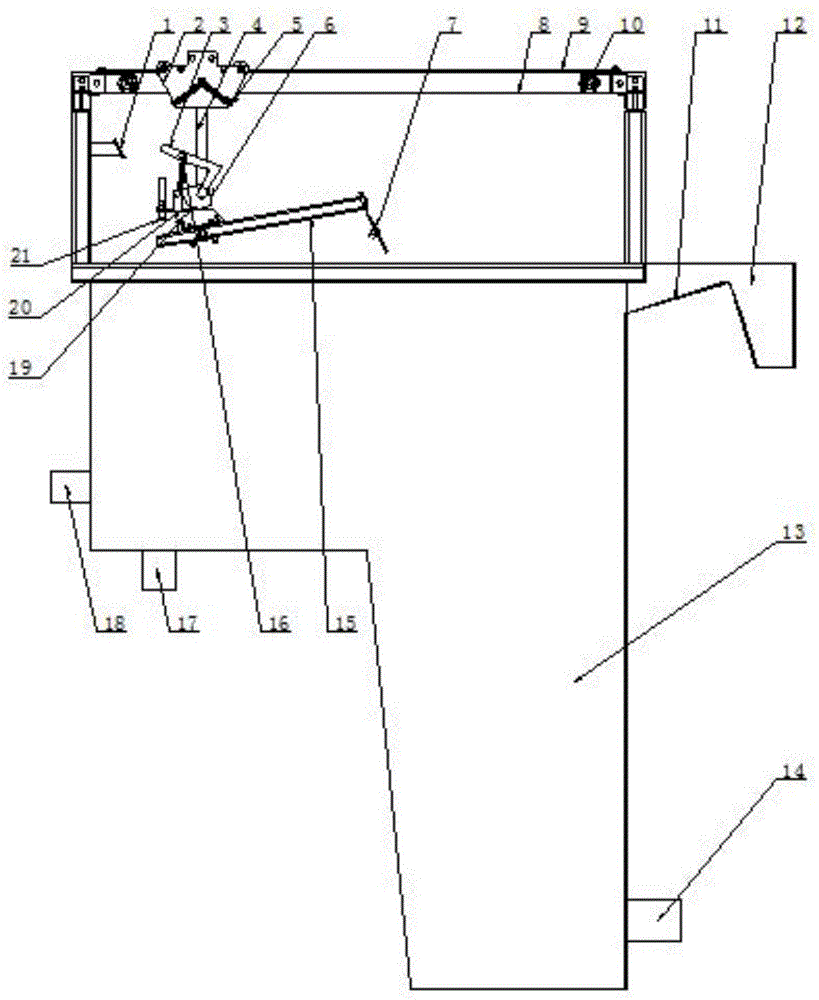

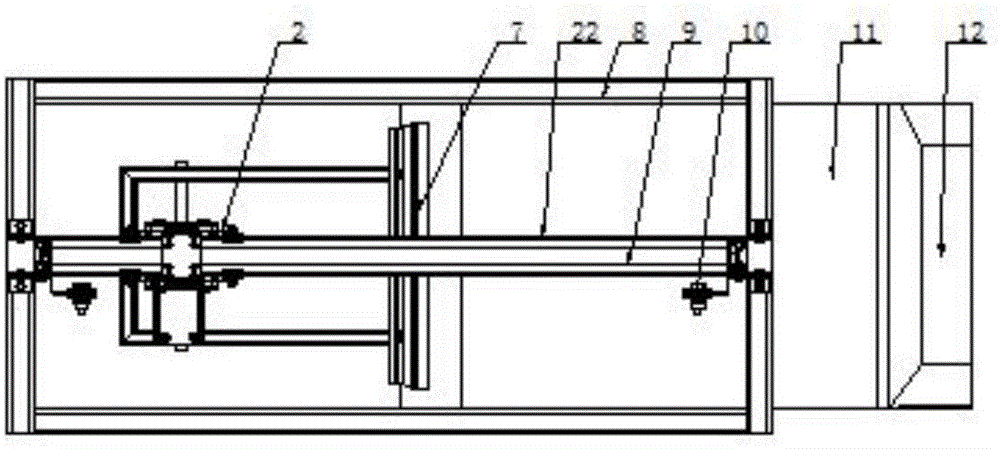

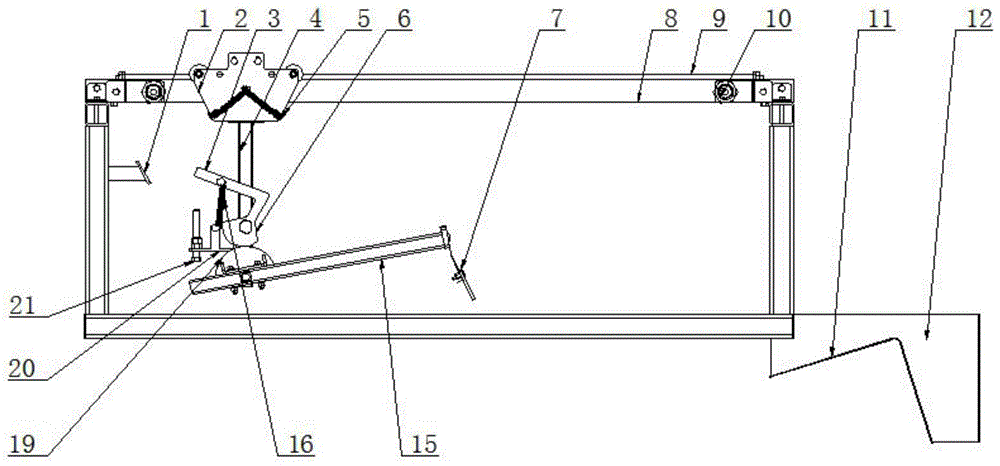

[0026] A slag scraper specially used for cleaning paint slag in a spray booth, the slag scraper includes a frame 8, a guide rail 22, a cylinder 9, a moving trolley 2, a cam lock slag releasing mechanism, and a liquid storage tank 13, on which A medicament inlet 17 , a liquid to be treated inlet 18 and a treatment liquid outlet 14 are provided. The frame is fixed on the liquid storage tank, the cylinder is a rodless cylinder, the guide rail and the cylinder are installed on the frame, electromagnetic induction limit switches 10 are respectively installed on the frame at both ends of the guide rail, and the moving trolley is slidably installed on the guide rail. Driven by a cylinder, limit rollers 5 are installed at both ends of the lower part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap