A method for quickly tightening screen mesh and vibrating sieve

A sieve and tensioning technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve problems such as large impact on production and no good solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

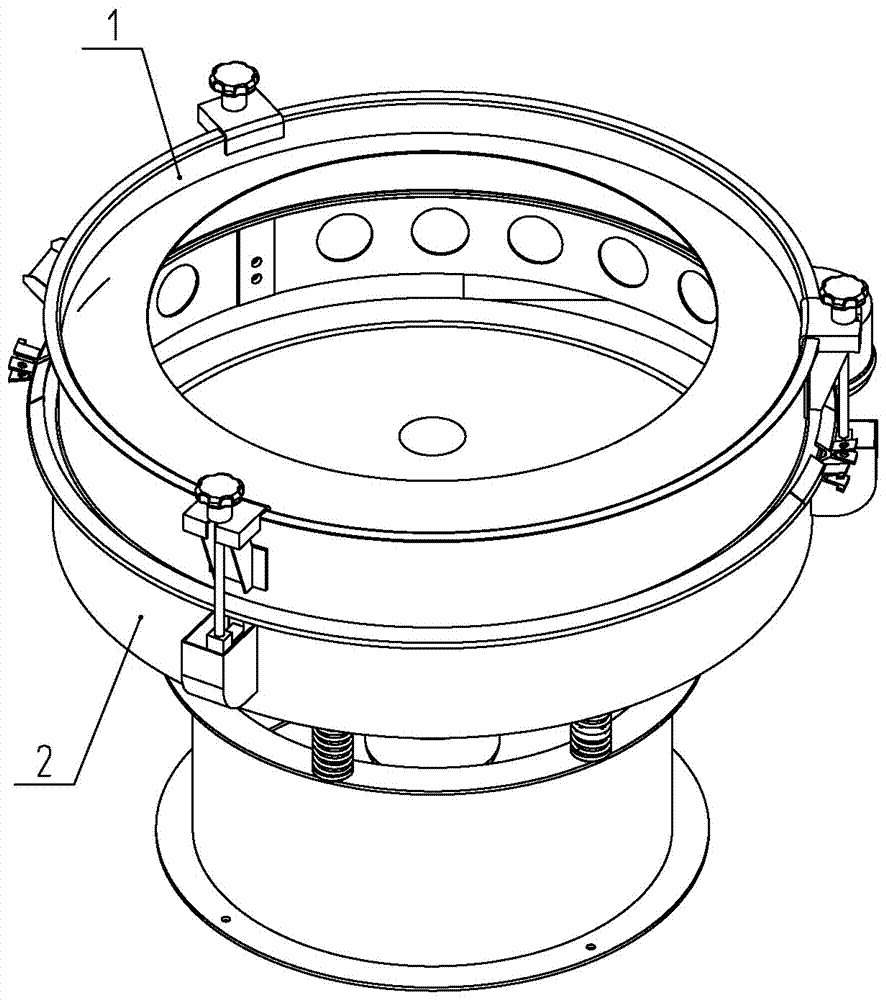

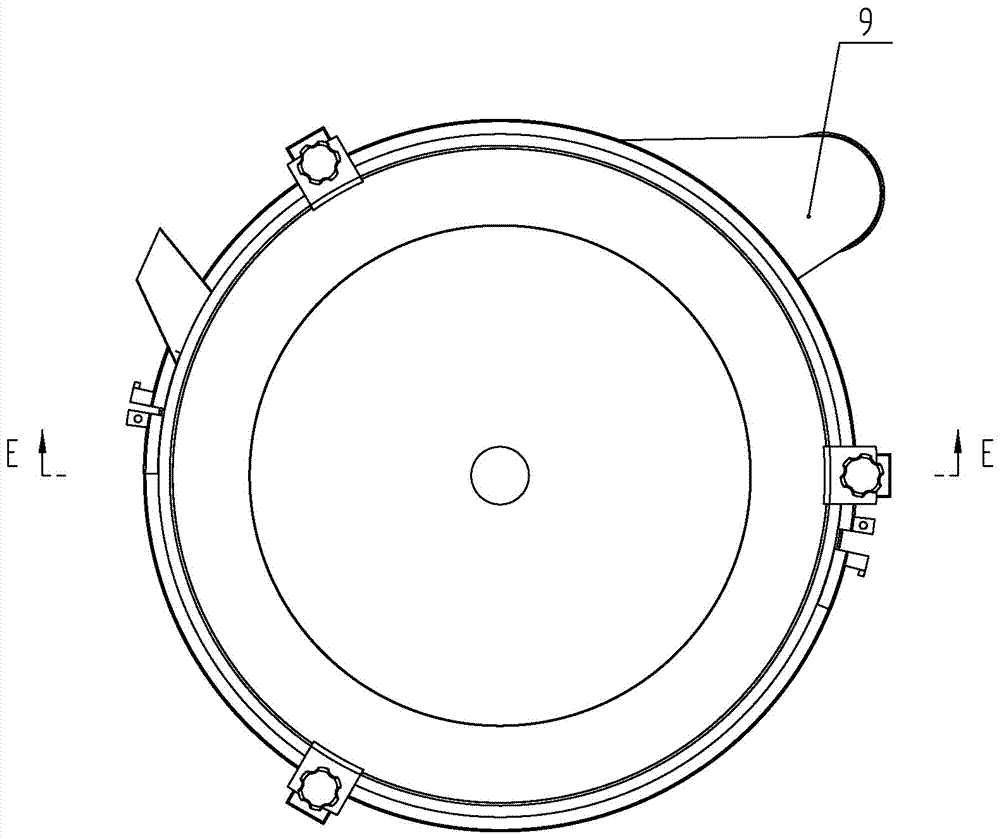

[0041] Such as Figures 1 to 4 As shown, the main part of the vibrating screen includes an upper screen frame 1, a lower screen frame 2, a screen mesh, a press ring and a tension ring. The tension ring is arranged below the screen cloth, and the pressure net ring is fixedly arranged at the bottom of the upper screen frame 1 . The connection between the upper and lower screen frames is provided with a flange structure, and the specific connection method is that the lower end of the upper screen frame 1 is provided with a first flange, and the upper end of the lower screen frame 2 is provided with a second flange. The first flange is aligned with the second flange, and the edge portion of the screen is clamped by the first flange and the second flange. The inner diameter of the upper screen frame 1 is smaller than that of the lower screen frame 2, so when the first flange and the second flange are aligned, the first flange must protrude a part inward to form an annular boss str...

Embodiment 2

[0050] Compared with Embodiment 1, the clamping mechanism in this embodiment can adopt the following scheme:

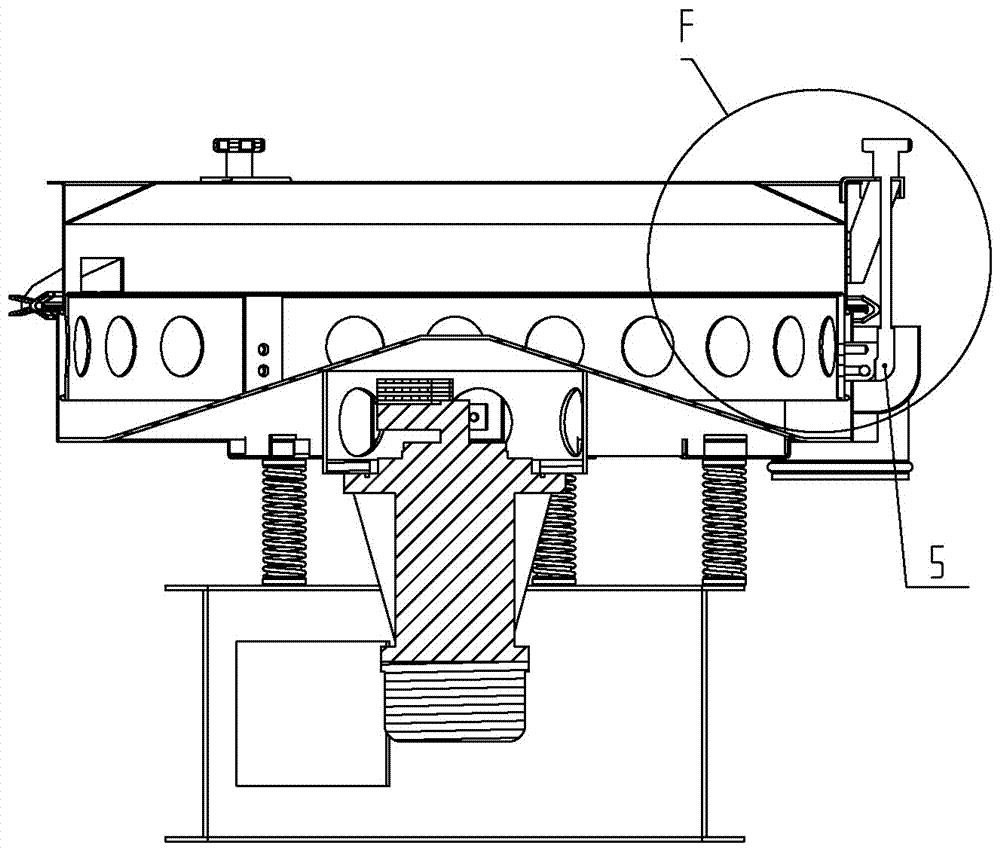

[0051] Such as Figures 5 to 11As shown, the jacking mechanism includes a pedestal 5.1, a tension bolt 5.2 and a C-shaped hook body 5.3; a notch is opened on the lower screen frame 1, the pedestal 5.1 is fixed on the outer wall of the upper screen frame 1, and the tension bolt 5.2 is vertically arranged on the On the pedestal 5.1, the lower end is processed with external threads; the upper end of the C-shaped hook body 5.3 has a threaded hole and is connected with the tension bolt 5.2 through a thread pair, and the lower end of the C-shaped hook body 5.3 passes through the notch and the tension ring 10 connect.

[0052] Although there is no direct fixed relationship between the tension bolt 5.2 and the pedestal 5.1, since the tension ring 10 can contact the screen 3 and be tightened by pressure, and three tightening mechanisms are provided at the same time, the tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com