Woodworking round carving machine

A round engraving machine and woodworking technology, which is applied in the fields of engraving and decorative arts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0017] The most critical idea of the present invention is: removing the original fixture of the woodworking round engraving machine, retaining the original engraving head structure, and installing a double-layer workbench at the same time, the surface engraving of large-sized wood can be realized.

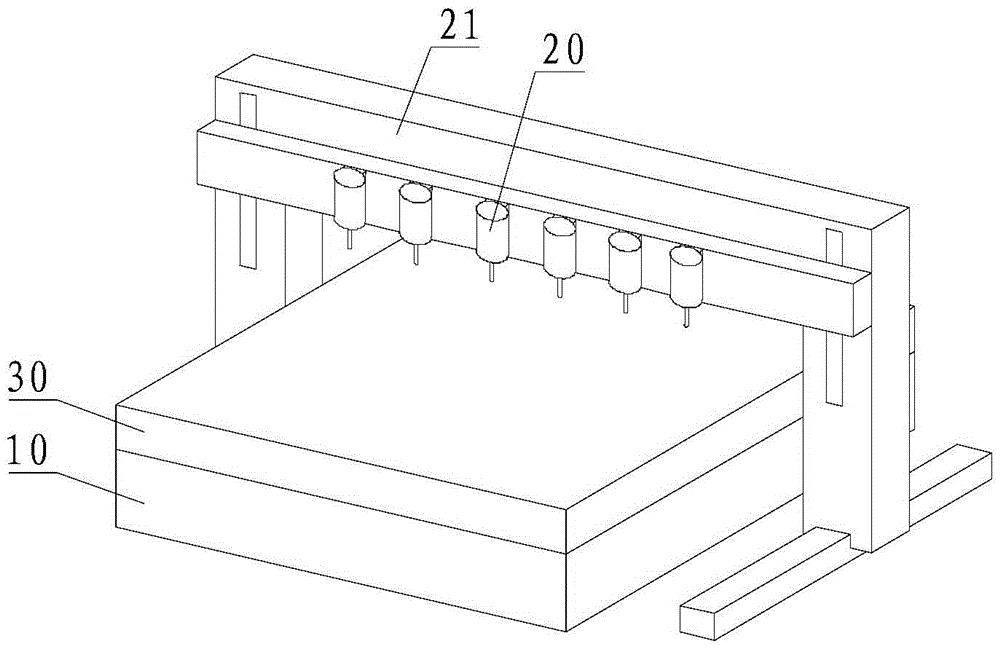

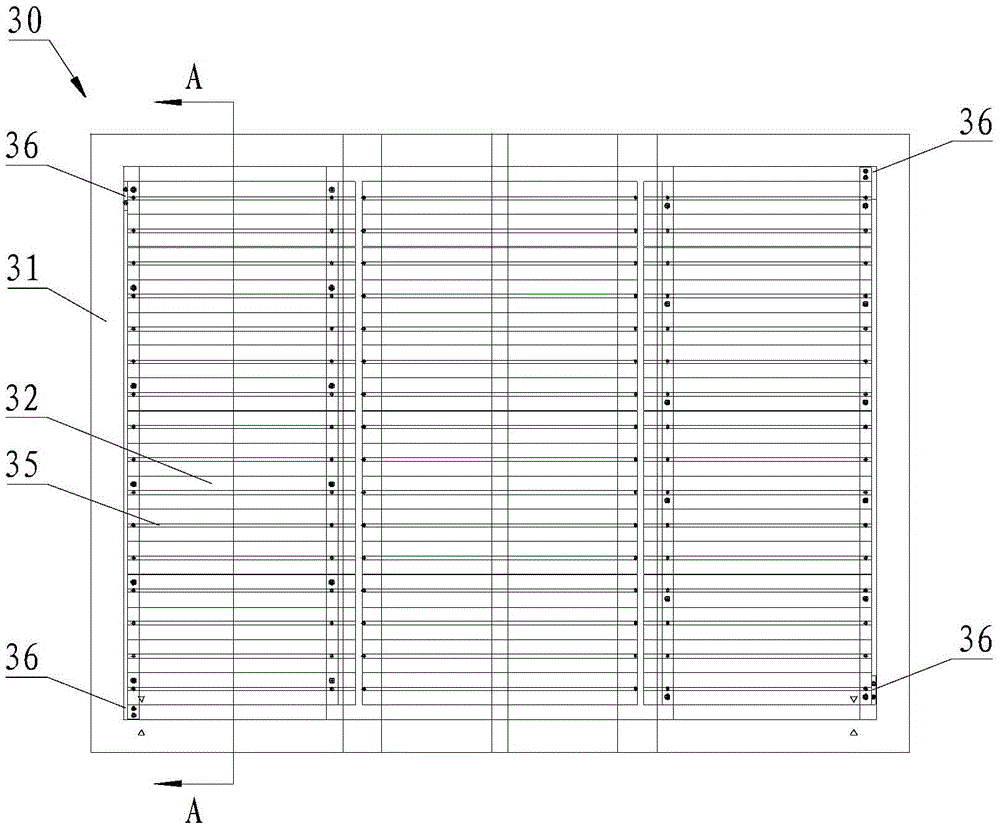

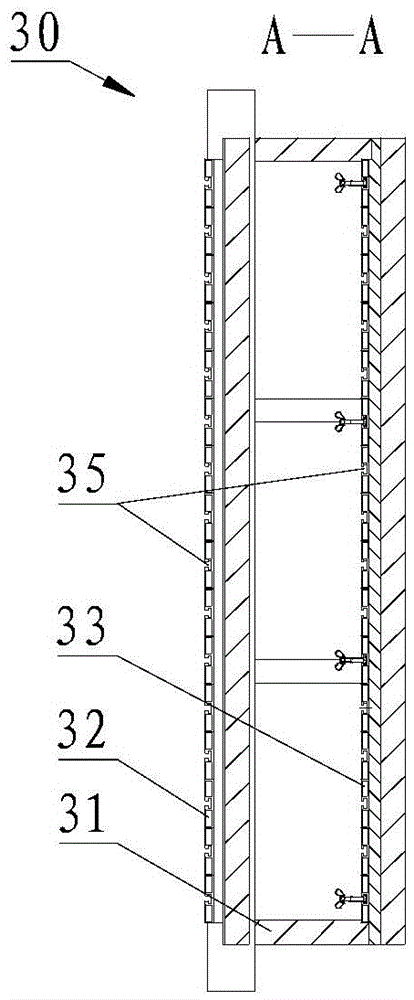

[0018] see Figure 1 to Figure 6 , a woodworking round engraving machine, comprising a machine base 10 and an engraving head 20, said machine base 10 is provided with multiple sets of screw rods arranged horizontally and parallel to each other, said engraving heads 20 are installed in a row on the base of the machine 10 above the mobile frame 21 also includes a double-layer workbench 30 detachably installed on the machine base 10, and the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com