Automatic binding system and binding method for roll-roll deck of ship

A ro-ro and deck technology, applied in the direction of detachable decks, devices to prevent multi-way movement of goods, etc., can solve the problems of low efficiency, long time of ships in port, easy omission, etc., to reduce labor intensity, improve lashing efficiency, The effect of reducing omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

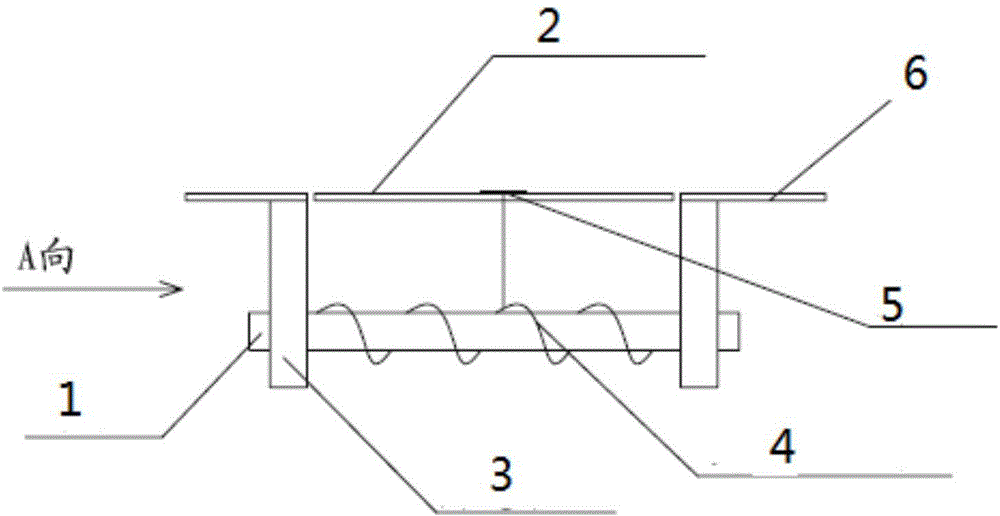

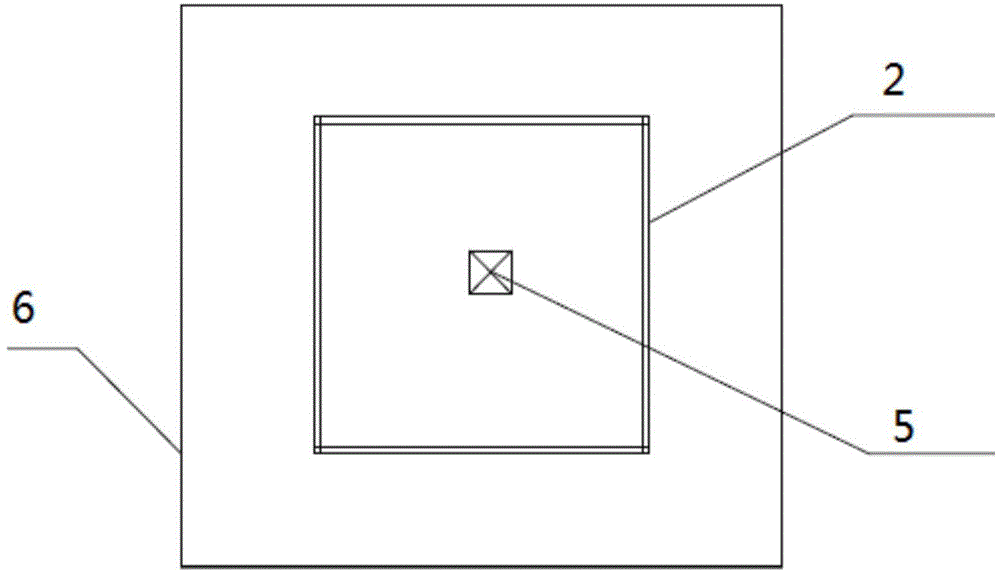

[0031] see Figure 1-5 , The ship ro-ro deck automatic lashing system consists of a lashing strap storage box and an automatic brake.

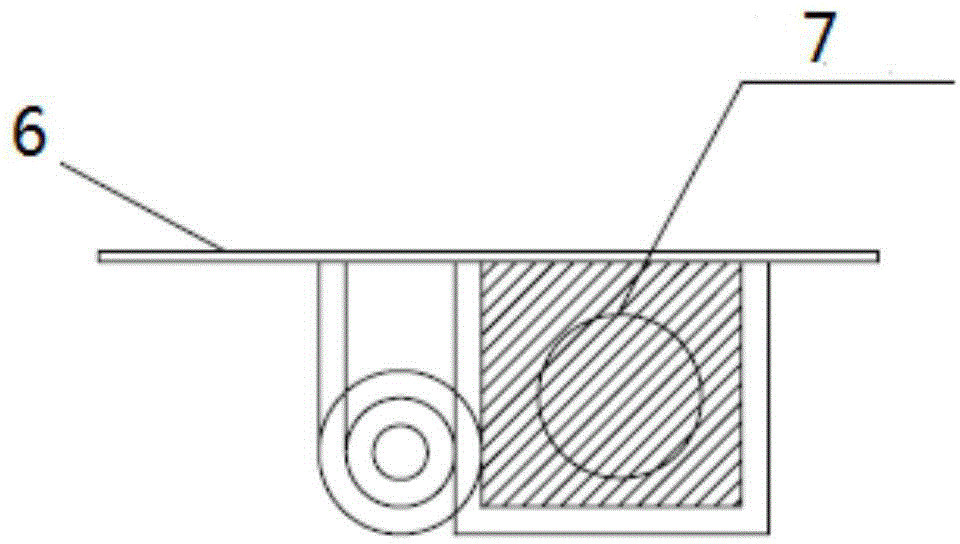

[0032] Binding strap storage box is made up of fixed eye ring 3, roller 1, binding wire rope 4, band hole small hatch 2, binding strap locking mechanism block 7. The locking mechanism block 7 of the binding belt can be constructed with reference to the locking mechanism of the safety belt of the car. When in use, slowly pull the binding buckle 5, the binding belt locking mechanism block 7 runs, and the binding belt 4 can be pulled out; Automatic retraction.

[0033] The specific working process is as follows: after the vehicle stops at the designated position, the owner gets off the vehicle and presses the automatic brake button 8a, starts the automatic brake 8, adjusts the position of the car body, lifts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com