A hoisting process for the overall entry and exit of the cabin cleaning vehicle

An overall, hoisting technology, applied in the directions of storage devices, loading/unloading, transportation and packaging, etc., can solve the problems of long time, long time of ships in port, poor sense of customer service quality, etc., achieve short time, reduce port Good effect of time and fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

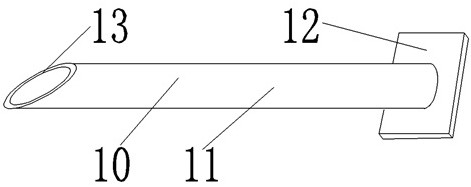

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

[0030] Taking the main rope of the gantry crane commonly used in the wharf to lift the forklift to the 180,000-ton capesize ship as an example, before formulating the hoisting process of the overall entry and exit of the clearing vehicle, the force calculation of the main rope used in the process is carried out. Wherein the main rope comprises two support ropes and two opening and closing ropes.

[0031] The specification of the main rope is 6*Fi(29)+IWRC-40 type steel wire rope, and its allowable tension is:

[0032] P=d 2 × R 0 × K / ÷1000÷K=126KN

[0033] Among them: d - wire rope diameter, 40mm;

[0034] R 0 ——Nominal tensile strength of steel wire rope, 1770MPa;

[0035] K / ——The minimum breaking force coefficient, 0.356;

[0036] K - safety factor, 8.

[0037] According to force analysis, when the gravity of the forklift is constant, the greater the inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com