systems for handling cargo

A technology for goods and cargo ships, applied in the direction of goods, vehicles used for freight, and operation modes, etc., can solve the problems of inability to transport, limit the choice of mechanization, etc., and achieve the effect of reducing time in port and expanding market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

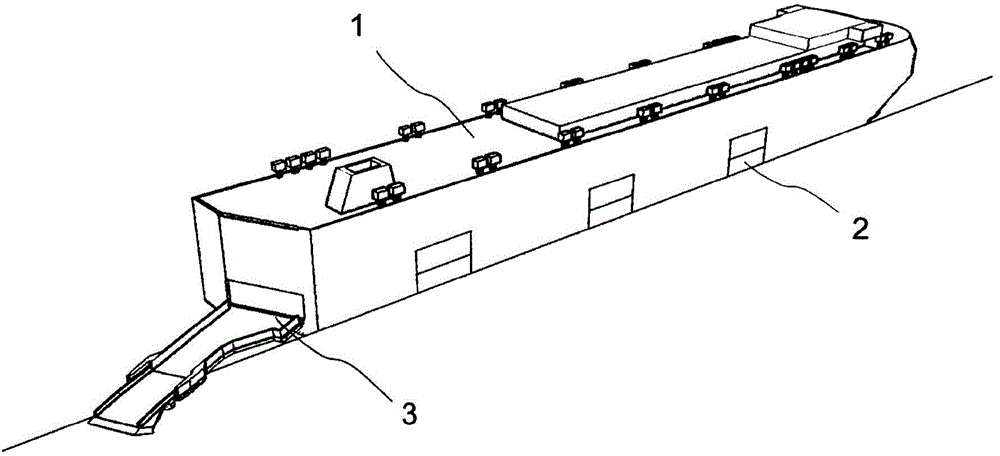

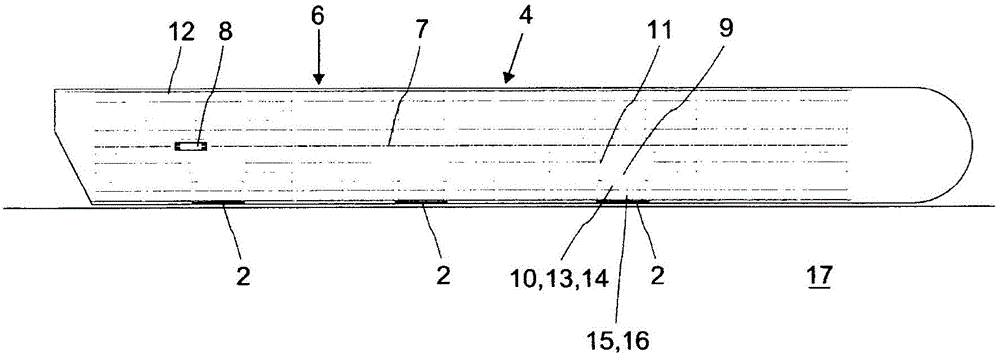

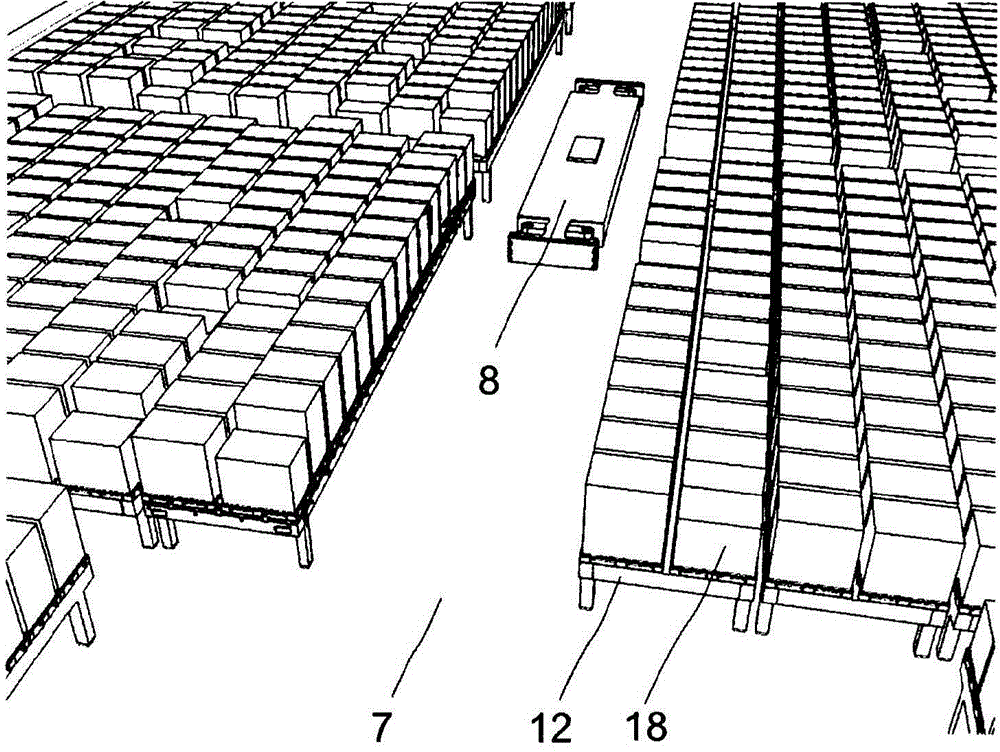

[0053] The present invention relates to a system for handling cargo on board a cargo ship and between the ship and the wharf. The system consists of three elements: a cargo ship, a loading platform for storing the cargo, and a specialized trolley for transporting the loading platform.

[0054] figure 1 A cargo ship 1 according to the invention is shown. The ship comprises a plurality of decks, one of which, the main deck, is accessible through side doors 2 . All decks are connected by cargo lifts. In addition, there is a rear skid 3 which folds down onto the quay to give access to cargo that cannot fit on a standard sized loading platform, as well as ro-ro cargo. Rear skids give access to a specially reinforced deck that can support heavy cargo.

[0055] figure 2 The main deck 4 is shown in plan view. The cargo is positioned on a loading platform 12 (described later) which is placed in a short slot 6 transverse to the longitudinal axis of the ship and has a central chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com