Structural member capable of replacing Australian ladder

A technology for structural parts and ladders, which is applied to ship accessories, ships, cargo handling equipment, etc., can solve the problems of increasing plate thickness and increasing the weight of ships, and achieves the effect of reducing the cost of using ships, reducing the weight of ships, and saving the weight of empty ships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

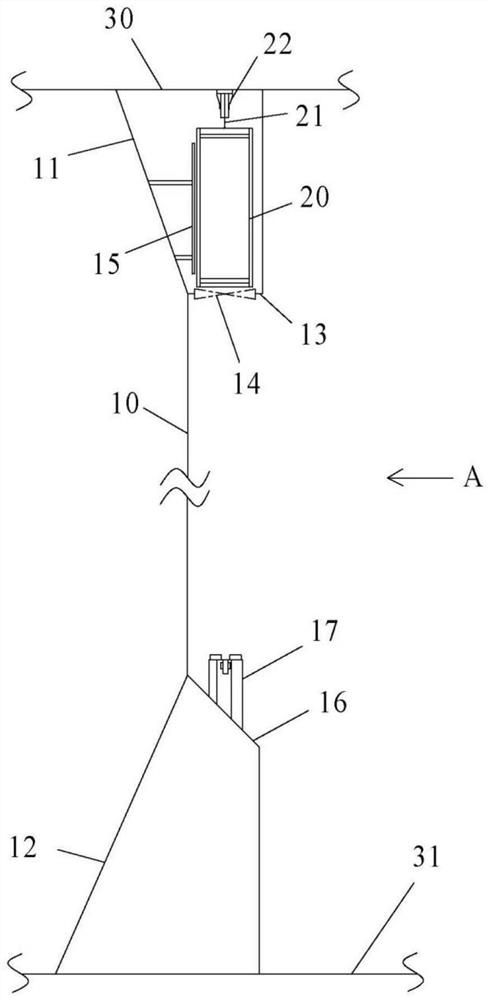

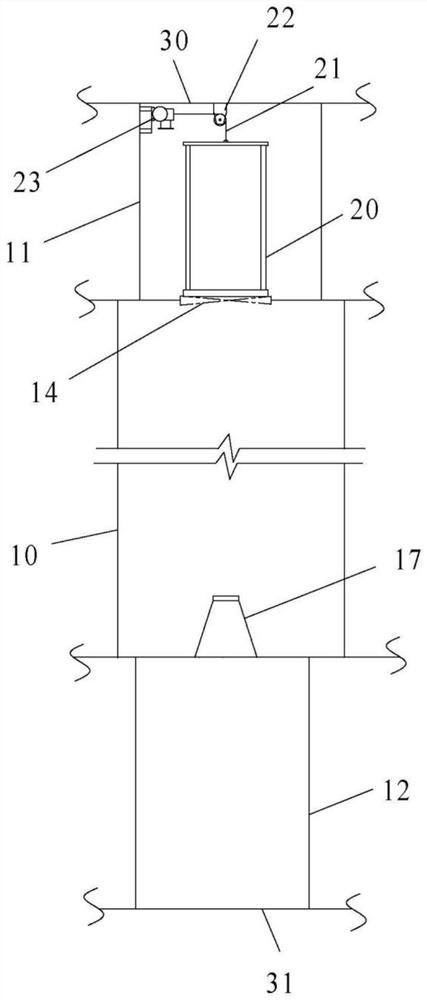

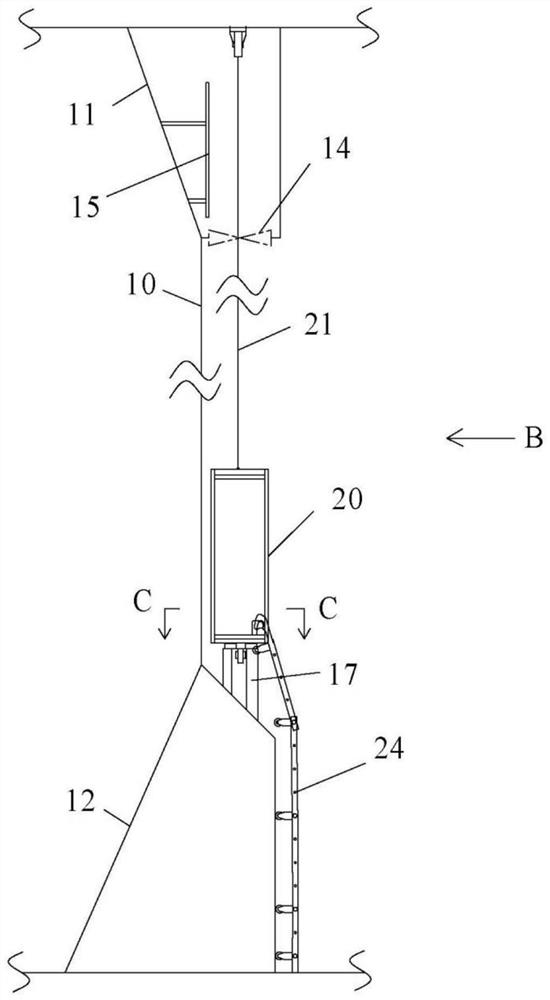

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a structural member that can replace the Australian ladder is arranged between the top pier 11 above the corrugated bulkhead 10 and the bottom pier 12 below the corrugated bulkhead.

[0025] The structural parts that can replace the Australian ladder include a lift box 20, a lifting cable 21 connected to the top of the lift box, a pulley block 22 located above the lift box and an electric winch 23 for controlling the lifting cable.

[0026] The block pulley 22 is fixed on the bottom of the main deck 30 .

[0027] The electric winch 23 is fixed on the inner wall of the top pier, and the lifting cable 21 is passed through the pulley block 22 .

[0028] The bottom plate 13 of the top pier is provided with a through hole 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com