Water flow impacting system of ship ballast tank

A water impact and ballast tank technology, applied in the field of ships, can solve the problems of costing a lot of manpower, material resources, time, etc., and achieve the effect of reducing the required time and reducing the time in port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

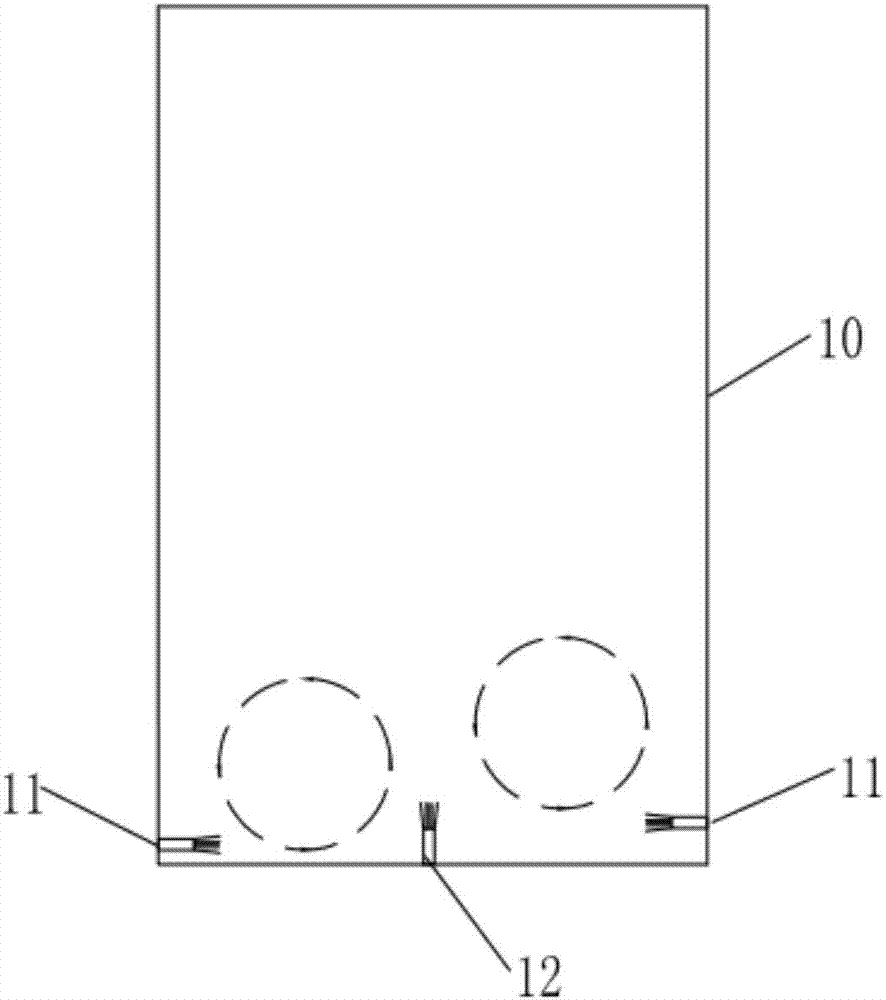

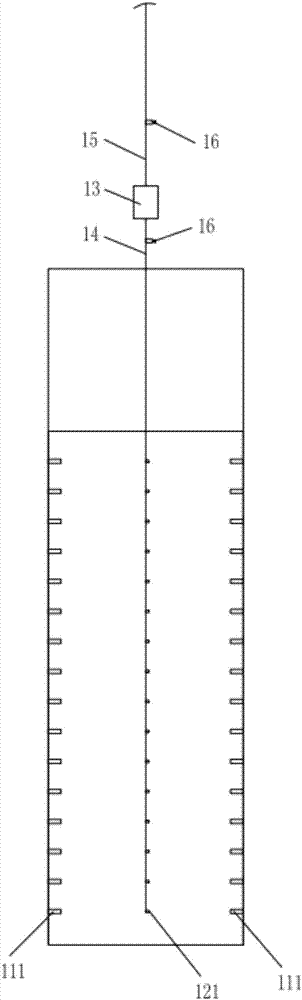

[0028] Such as figure 1 with figure 2 As shown, the present embodiment provides a ballast tank water impact system of a ship, comprising a first water nozzle group 11 composed of a plurality of first water nozzles 111, a second water nozzle group 121 composed of a plurality of second water nozzles 121. Water nozzle group 12, and water pump 13; Wherein, the first water nozzle group 11 is arranged on the sidewall of ballast tank 10, and the second water nozzle group 12 is arranged on the bilge of ballast tank 10; The water end communicates with the water source, and the water outlet end of the water pump 13 supplies water for the first water nozzle group 11 and the second water nozzle group 12 .

[0029] When the ballast water is injected into the ballast tank 10, the first water nozzle group 11 and the second water nozzle group 12 are opened, and the water flow ejected by each pair of the first water nozzle 111 and the second water nozzle 121 can be pressed against The silt ...

Embodiment 2

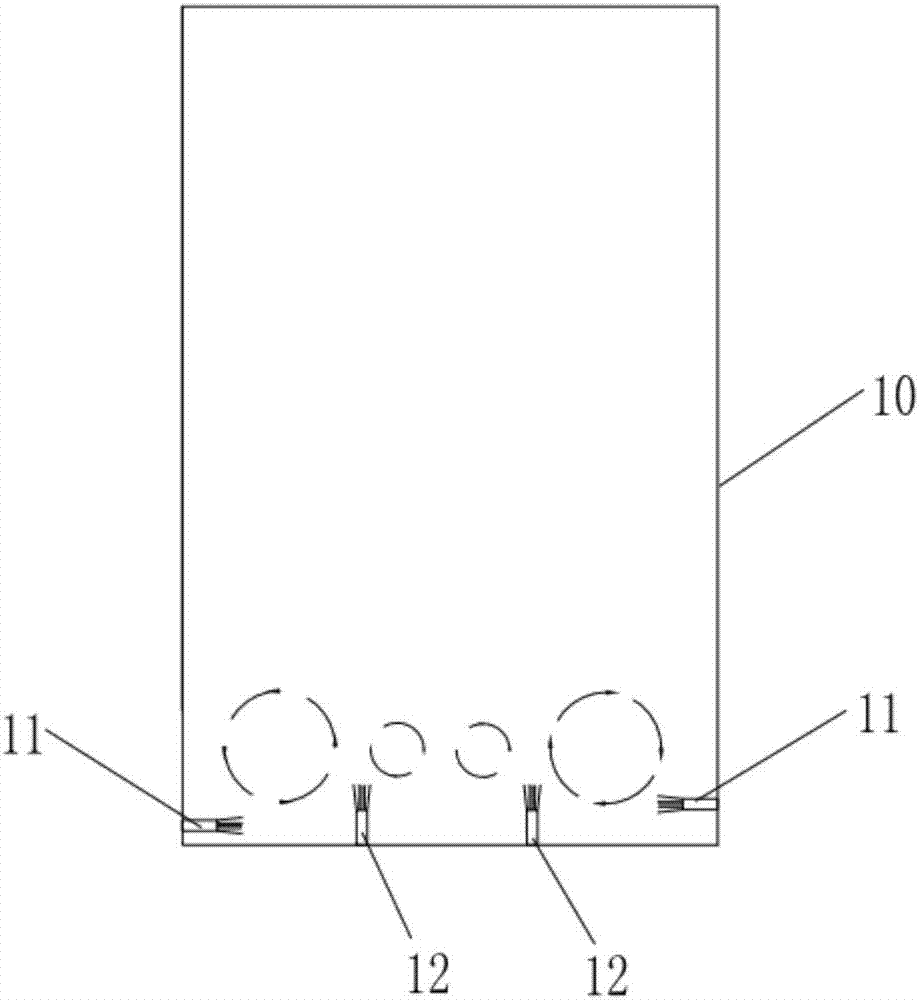

[0036] Such as Figure 3 to Figure 5 As shown, this embodiment provides a ballast tank water impact system of a ship. For the sake of brevity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that in this embodiment, the first water nozzle The number of groups 11 is two groups, and they are respectively arranged on two opposite side walls of the ballast tank 10; The bilges of 10 are distributed at intervals and correspond to two groups of first water nozzle groups 11 respectively.

[0037] The setting form of the second water nozzle group 12 has two kinds, one such as image 3 As shown, two groups of second water nozzle groups 12 are arranged vertically with the bilge; Figure 4 As shown, the two groups of second water nozzle groups 12 are all obliquely arranged on the bottom of the ballast tank 10, and the inclination direction of one group of second water nozzle groups 12 is different from the inclination direction of the other gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com