Method and system for automatically balancing ship body of large cargo ship with ballast function

A technology of automatic balance and hull, which is applied in the direction of ship safety, transportation and packaging, ships, etc., can solve the problems of hull imbalance, etc., and achieve the effect of easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

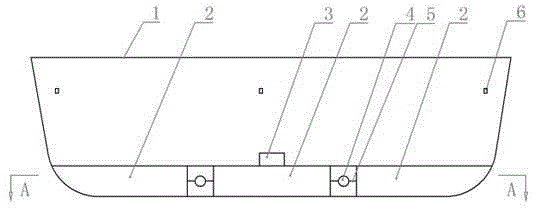

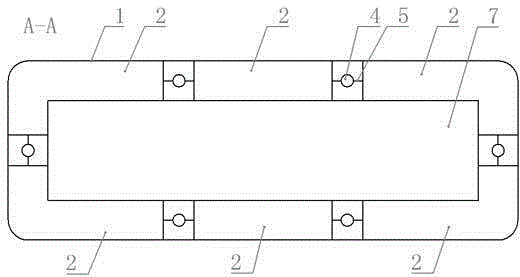

[0014] see figure 1 and figure 2 , the present invention has a large-scale cargo ship hull automatic balancing system with ballast function, including a ballast water tank 7 located at the bottom of the hull 1 and a ballast water treatment system (prior art) supporting it, characterized in that, in the There are at least four mutually independent balancing bins 2 around the bottom of the ballast water bunker 7 described above, and each balancing bin 2 is connected by a pipeline 5, and a water pump 4 is installed on each pipeline, and each water pump 4 is balanced by The controller 3 controls, when the cargo loaded on the hull is unbalanced, adjusts the water volume in each balance chamber 2 to keep the balance of the hull 1 .

[0015] The balance controller 3 adopts a sensor gyroscope, and is based on the horizontal plane. Once the weight of the cargo at one end of the hull is large, the hull at this end will sink a large distance, and the hull will tilt here. The balance co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com