Non-efflorescence high-strength tile adhesive

The technology of tile adhesive and efflorescence inhibitor is applied in the field of high-strength tile adhesive, which can solve the problems of impermeability, falling off of cement slurry, and difficulty in guaranteeing construction quality, and achieve the effects of inhibiting efflorescence, improving bonding strength and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

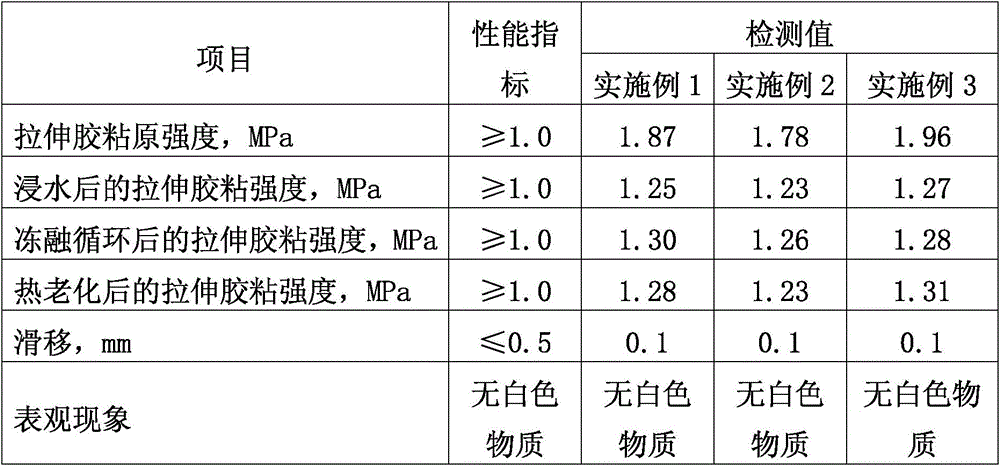

Examples

Embodiment 1

[0015] Weigh 26g of high alumina cement, 46g of fly ash, 14g of blast furnace slag, 8g of Shuangfei powder, 4g of styrene-acrylic acid copolymer latex powder, 1g of polydimethylsiloxane, 0.5g of carboxymethyl cellulose ether, ERA100 panthene Inhibitor 0.5g is put into a blender, and all raw materials are mixed and stirred evenly to obtain an efflorescence-free high-strength tile adhesive.

Embodiment 2

[0017] Weigh 23g of high alumina cement, 50g of fly ash, 13g of blast furnace slag, 10g of Shuangfei powder, 3g of ethylene-vinyl acetate copolymer latex powder, 0.5g of polydimethylsiloxane, 0.1g of methyl cellulose ether, carboxyethyl Put 0.1 g of cellulose ether and 0.3 g of ERA100 efflorescence inhibitor into a blender, and mix and stir all the raw materials evenly to obtain an efflorescence-free high-strength tile adhesive.

Embodiment 3

[0019] Weigh 30g of high alumina cement, 42g of fly ash, 15g of blast furnace slag, 6g of Shuangfei powder, 6g of ethylene-vinyl acetate copolymer latex powder, 0.6g of polydimethylsiloxane, 0.1g of carboxypropyl methylcellulose ether, Put 0.1 g of carboxyethyl cellulose ether and 0.2 g of ERA100 efflorescence inhibitor into a mixer, and mix and stir all the raw materials evenly to obtain an efflorescence-free high-strength tile adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com