An automatic sewing unit sewing machine head position lifting device

A lifting device and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of inconvenient sewing machine needle loading, thread replacement and maintenance, and limit the space range of sewing machine threading and thread passing, and achieve The interlocking structure is ingeniously designed, the adjustment distance is fixed, and the effect of expanding the space range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

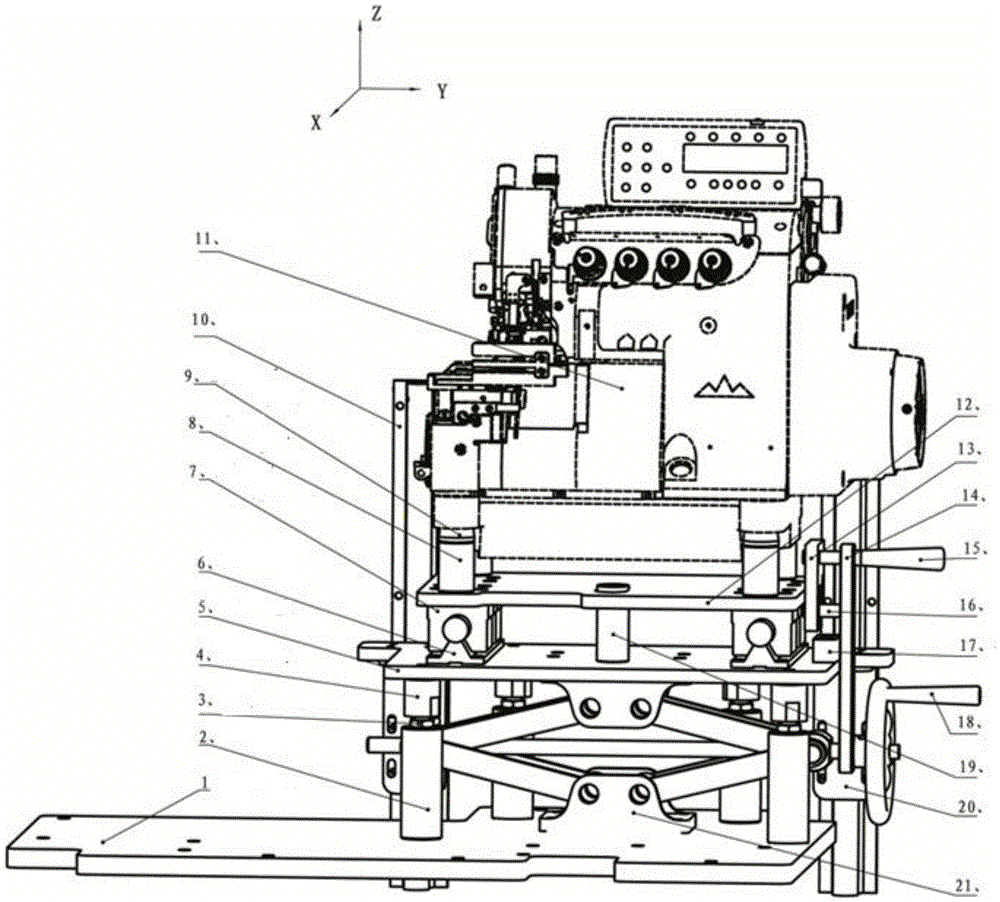

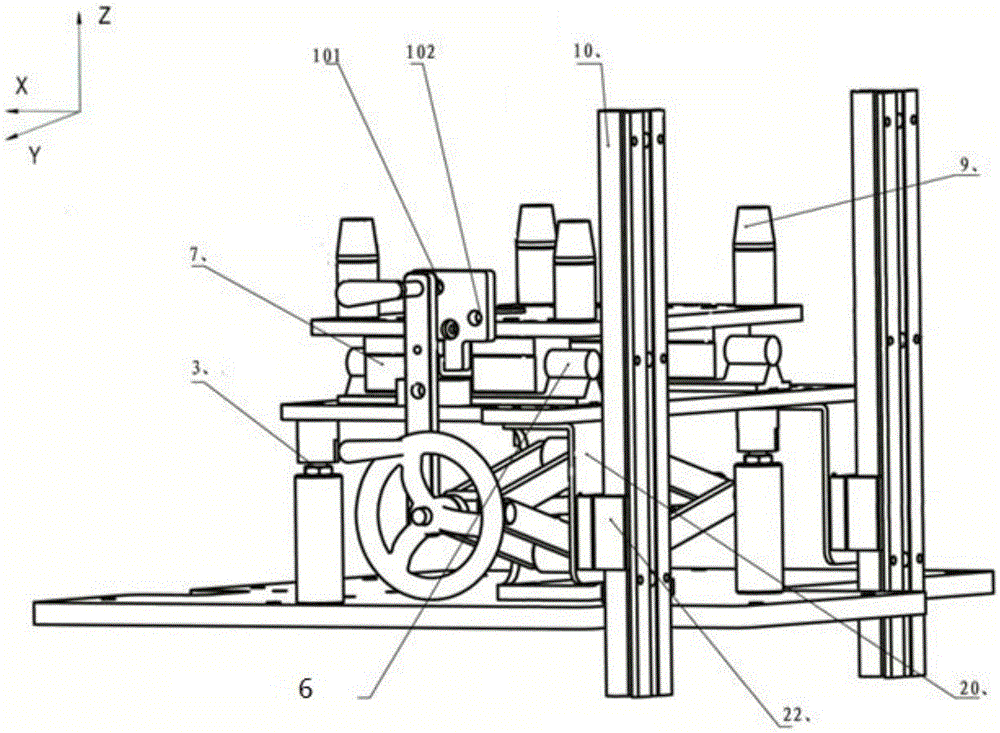

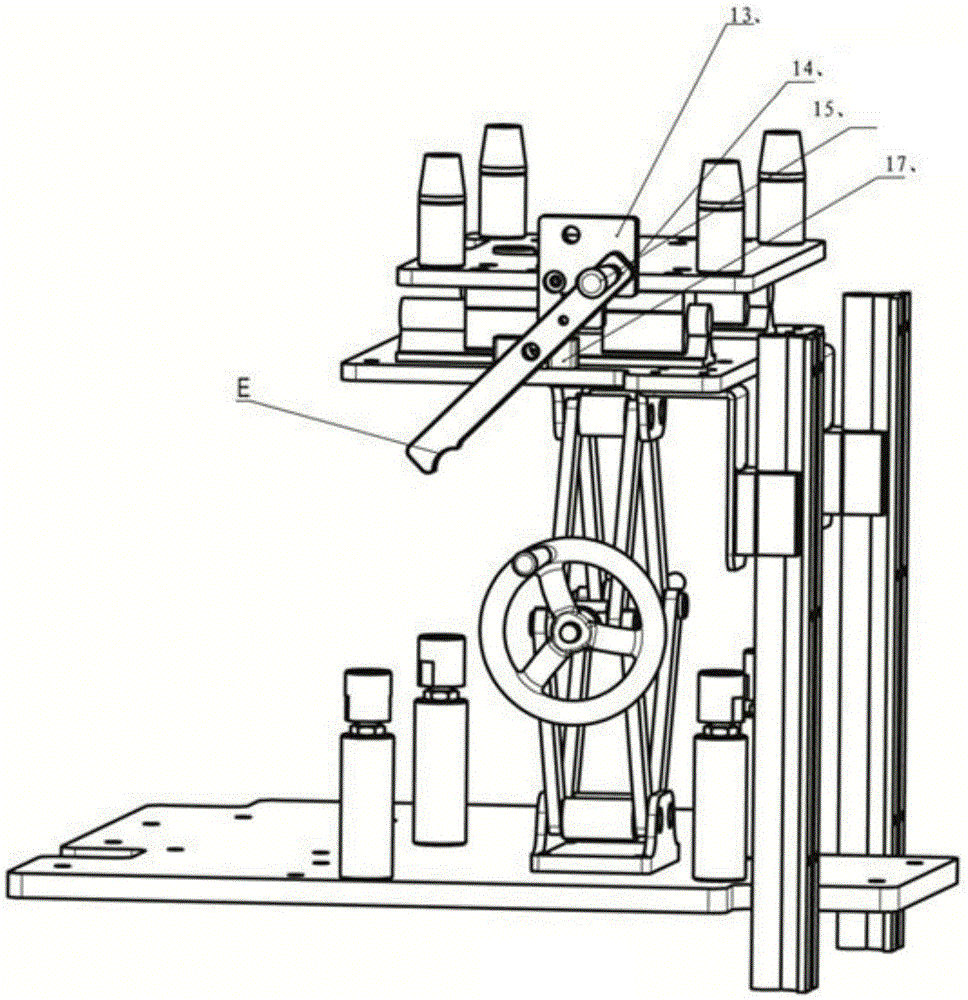

[0021] see Figure 1-3 , the automatic unit sewing machine head position lifting device, including the sewing machine body, the body base 1, the first chassis 5 cooperates with the four-bar jack 21 and the vertical guide rail 10 is responsible for lifting, and the vertical guide rail 10 moves up and down in the Z direction, The main purpose is to raise the sewing machine to a high place to complete needle changing, threading and maintenance work; the direction of the second chassis 12’s forward and backward movement is the X direction, and the interlocking parts of the linear guide rail 6 and the pulling rod allow the sewing machine to avoid the automatic auxiliary parts and detection parts. Further up the sewing machine, the interlocking part of the pulling bar is to first return the sewing machine to the safe lifting position through the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com