A large-scale aerial slope adjustment hoisting system and its application

A kind of slope and large-scale technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems that it is difficult to meet the needs of full-scale scaffolding support sites, the economy and safety cannot be satisfied, and the tonnage of steel structure bridges is large. Save and temporarily support materials, meet the design intent, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

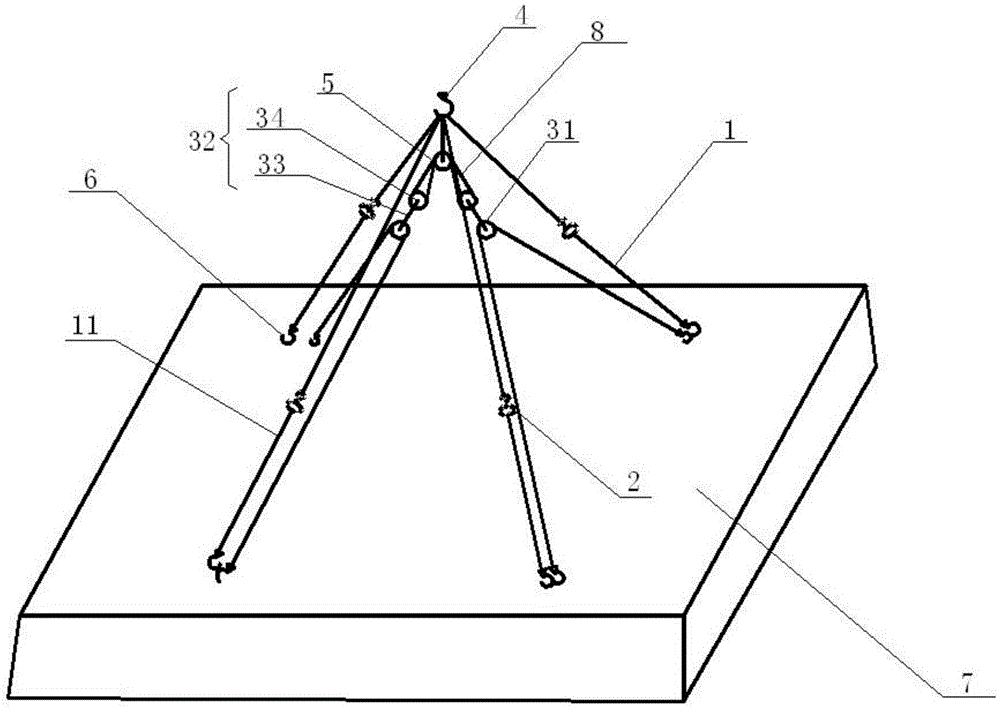

[0023] Referring to the accompanying drawings, a detailed description will be given of a large-scale aerial slope adjustment hoisting system of the present invention.

[0024] A large-scale aerial gradient adjustment hoisting system includes an adjustment cable 1, a balance cable 2, a transmission wheel 3, a hook 4, and a hook pulley 5, such as figure 1 As shown, there are four adjusting cables 1 , a chain block 11 is provided at the lower end of the adjusting cables 1 , the upper end of the adjusting cables 1 is hung on the hook 4 , and the adjusting cables 1 are connected to the box girder 7 through the lifting lug 6 . The present invention adopts chain block 11, which is strong and wear-resistant, has high safety performance and is convenient for adjustment. Such as figure 1 As shown, there are two balance cables 2, the ends of which are directly hung on the box girder 7 through lifting lugs 6 respectively, and the two balance cables 2 pass through the transmission wheel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com