Skid-mounted air discharge recovery system and recovery method

A recovery system and jetting technology used in earth-moving drilling, fluid production, wellbore/well components, etc., to protect the environment, facilitate maintenance, and reduce installation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

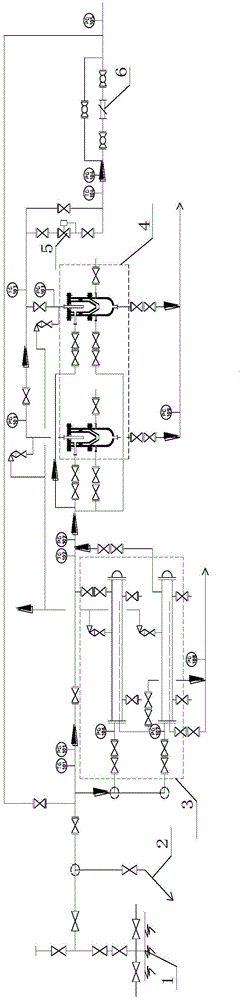

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the skid-mounted blowout gas recovery system includes a blowout prevention pipeline 2, a primary sand removal device 3 and a secondary sand removal device 4, and the primary sand removal device 3 and the secondary sand removal device 4 are all set in on a removable chassis. The primary desander device 3 includes two parallel primary desanders, and the secondary desander device 4 includes two parallel secondary desanders. There is a tee I7 between the wellhead and the oil nozzle, and the pipeline leading from the production test wellhead is respectively connected to the blowout prevention pipeline 2 and the air inlet of the first-stage sand removal device 3 through the three-way I7, and the gas outlet of the first-stage sand removal device 3 is connected to the second The air inlet connection of stage desanding device 4. The air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com