Electromagnetic wave resistivity logging-while-drilling tool

A logging-while-drilling tool and resistivity technology, which is applied in the field of drilling, can solve the problems of complex manufacturing process and high process requirements, and achieve the effects of simplifying the manufacturing process, simplifying the process flow, and being easy to expand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

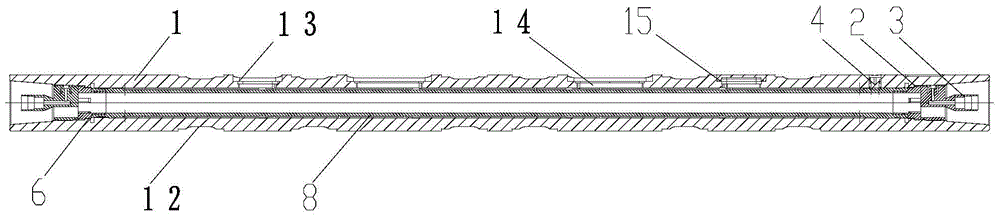

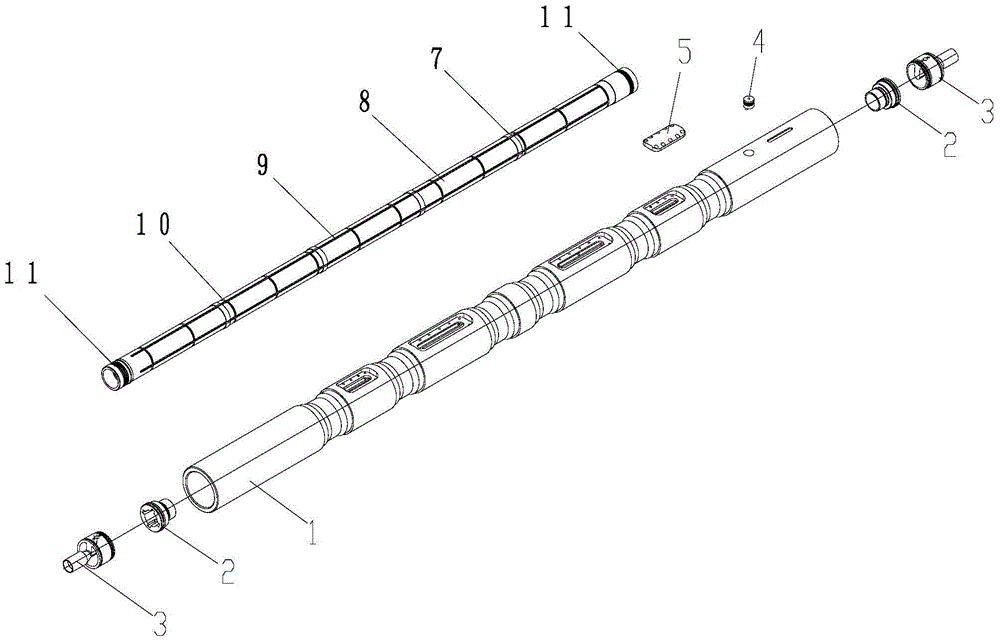

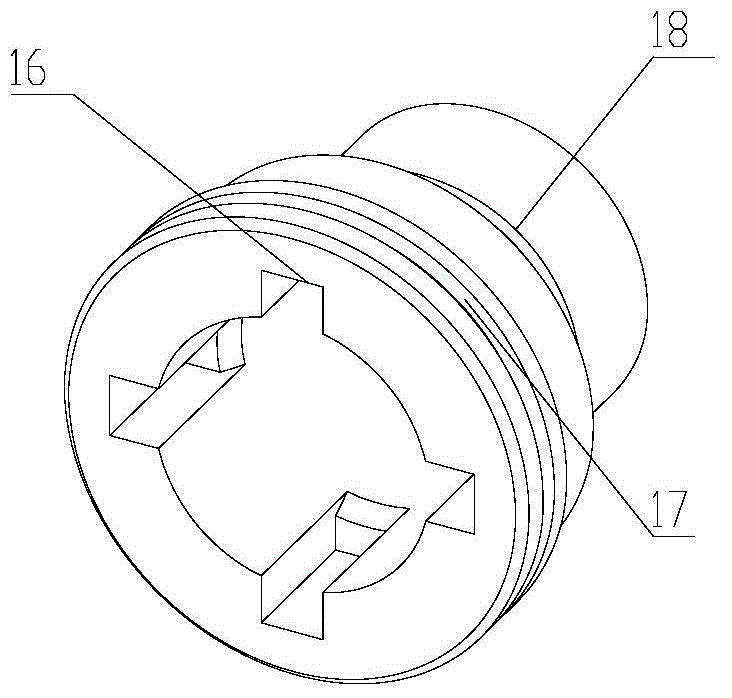

[0027] see Figure 1 to Figure 4 , an electromagnetic wave resistivity logging while drilling tool of the present invention, comprising an outer collar 1 and an inner collar 8 arranged in the outer collar 1, the positioning hole on the outer collar 1 and the positioning anti-rotation are passed between the outer collar 1 and the inner collar 8 The pin 4 is radially fixed, and the outer collar 1 and the inner collar 8 are assembled to form a sealed ring cavity; wherein, the two ends of the inner collar 8 are respectively provided with a locking ring 2 and a mud diversion sleeve 3, and the locking ring 2 is set in the inner collar 8, and the inner collar 8 is fixed by connecting the ACME thread 6 with the outer collar 1. The mud diversion sleeve 3 is set on the outer collar 1 and fixed radially with the outer collar 1 by screws. The mud diversion sleeve 3 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com