Air release plug of antiseep automobile transmission

A technology for automotive transmissions and exhaust plugs, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve the problems of exhaust plug loss of exhaust, increased lubricating oil pressure, etc., and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

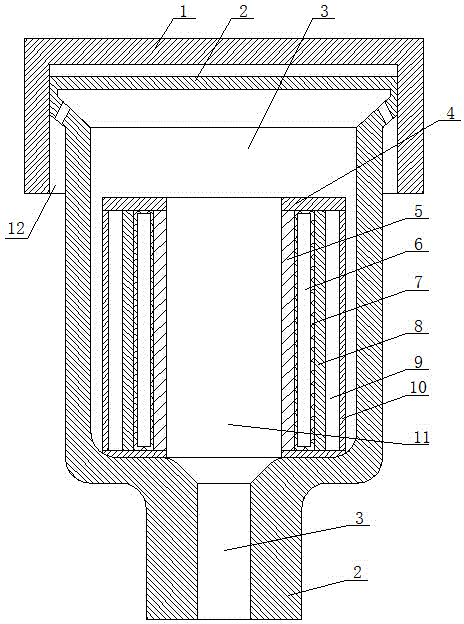

Embodiment 1

[0033]The air vent plug of the anti-leakage automobile transmission of the present embodiment comprises a plug cover and a plug body having an exhaust cavity, the plug cover is sleeved on the plug body, and an annular air outlet is formed between the inner wall of the plug cover and the outer wall of the plug , there is a ventilation pipe in the exhaust chamber, the ventilation pipe includes an outer shell and an inner shell with a cavity, the outer shell is sleeved around the periphery of the inner shell and forms a vacuum steam chamber, and the two ends of the outer shell are connected to the inner shell through end caps Together; the outer wall of the steam chamber is laid with a liquid-absorbing core, and the steam chamber is filled with working liquid; the lower end of the cavity of the inner shell is connected with the lower end of the exhaust chamber, and the upper end of the cavity of the inner shell is connected with the upper end of the exhaust chamber. communication;...

Embodiment 2

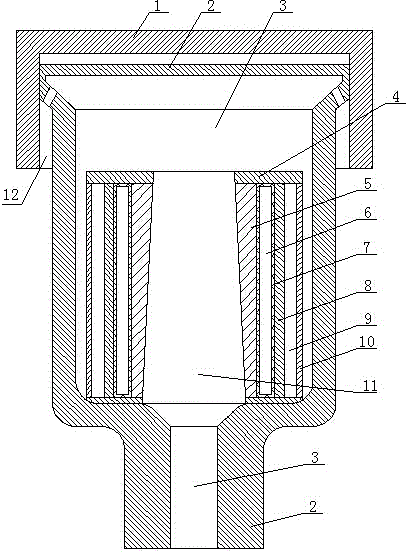

[0035] The air vent plug of the anti-leakage automobile transmission of the present embodiment comprises a plug cover and a plug body having an exhaust cavity, the plug cover is sleeved on the plug body, and an annular air outlet is formed between the inner wall of the plug cover and the outer wall of the plug , there is a ventilation pipe in the exhaust chamber, the ventilation pipe includes an outer shell and an inner shell with a cavity, the outer shell is sleeved around the periphery of the inner shell and forms a vacuum steam chamber, and the two ends of the outer shell are connected to the inner shell through end caps Together; the outer wall of the steam chamber is laid with a liquid-absorbing core, and the steam chamber is filled with working liquid; the lower end of the cavity of the inner shell is connected with the lower end of the exhaust chamber, and the upper end of the cavity of the inner shell is connected with the upper end of the exhaust chamber. Connected; th...

Embodiment 3

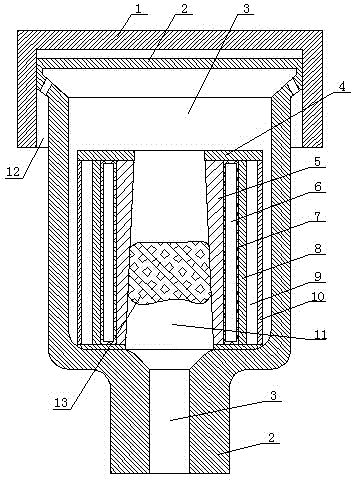

[0037] The air vent plug of the anti-leakage automobile transmission of the present embodiment comprises a plug cover and a plug body having an exhaust cavity, the plug cover is sleeved on the plug body, and an annular air outlet is formed between the inner wall of the plug cover and the outer wall of the plug , there is a ventilation pipe in the exhaust chamber, the ventilation pipe includes an outer shell and an inner shell with a cavity, the outer shell is sleeved around the periphery of the inner shell and forms a vacuum steam chamber, and the two ends of the outer shell are connected to the inner shell through end caps Together; the outer wall of the steam chamber is laid with a liquid-absorbing core, and the steam chamber is filled with working liquid; the lower end of the cavity of the inner shell is connected with the lower end of the exhaust chamber, and the upper end of the cavity of the inner shell is connected with the upper end of the exhaust chamber. Connected; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com