Oil fume check valve for range hood

A range hood and check valve technology, applied in the direction of oil fume removal, application, valve lift, etc., can solve the problems of returning smoke and smell, poor sealing, etc., and achieve the effects of preventing odor leakage, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

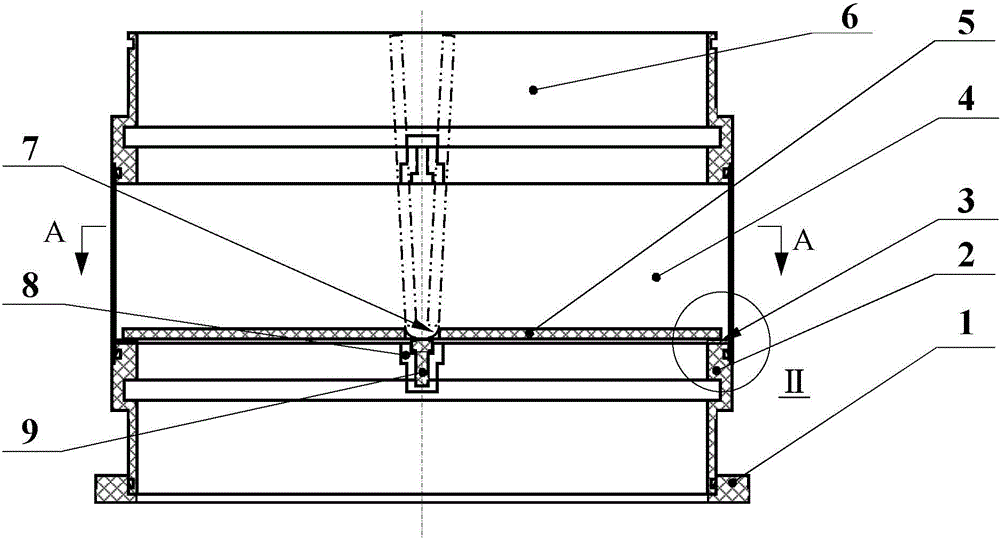

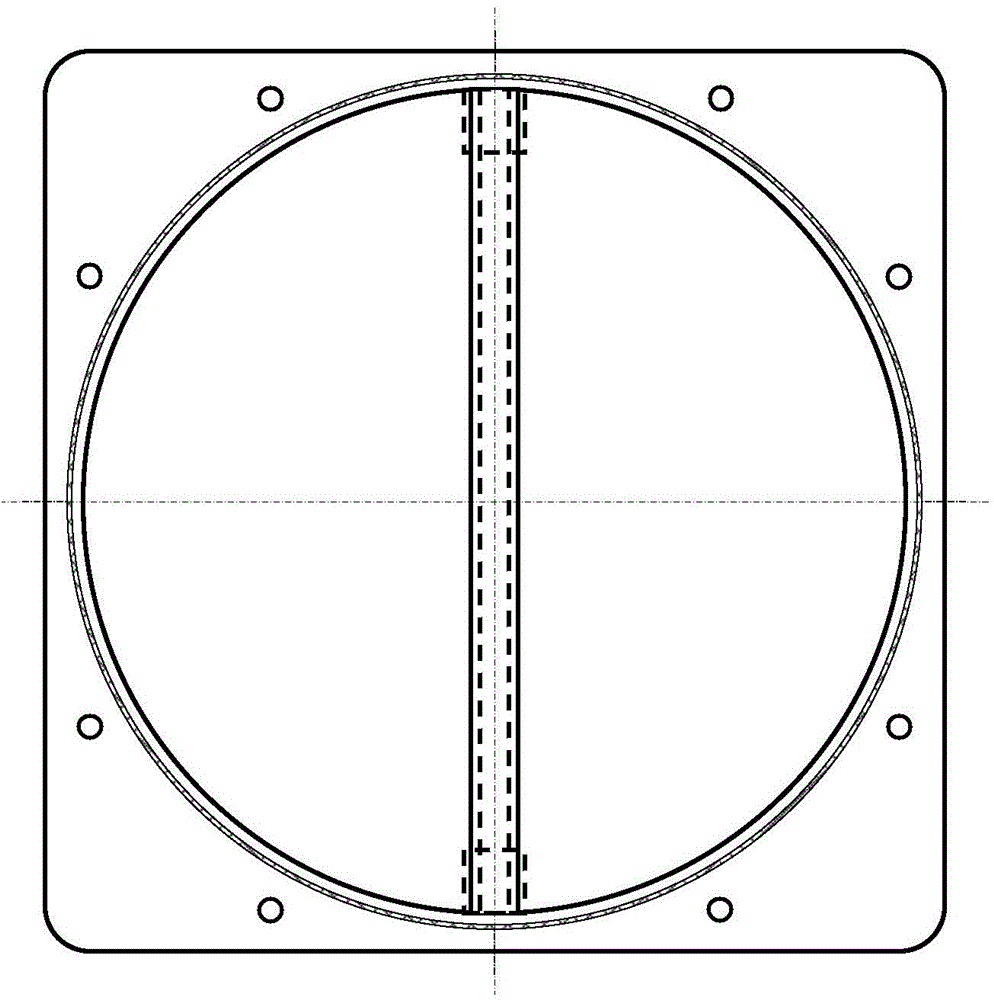

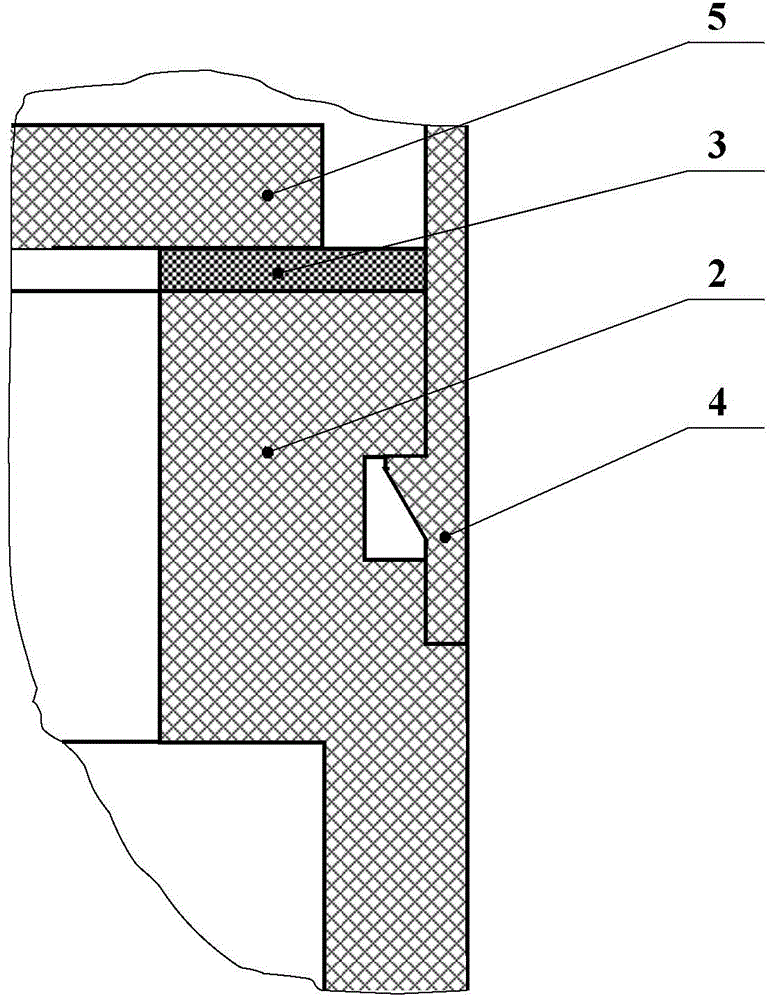

[0012] Specific implementation mode one: as Figure 1~4 As shown, the oil fume check valve for range hoods in this embodiment includes an installation interface 1, a housing and two flaps 5, and the oil fume check valve also includes a sealing layer 3, a support beam 9, two single The degree of freedom flexible hinge 7 and two support beam interfaces 8, the shell is composed of the upper shell 6, the middle shell 4 and the lower shell 2, the upper shell 6, the middle shell 4 and the lower shell 2 from top to bottom The bottom of the lower shell 2 is covered with an installation interface 1, and the inner wall of the lower shell 2 is symmetrically provided with two support beam interfaces 8, and the two ends of the support beam 9 are overlapped on the two support beam interfaces 8. , each flap 5 is connected to the side of the support beam 9 through a single-degree-of-freedom flexible hinge 7, the outer edges of the two flaps 5 overlap the upper end surface of the lower shell 2...

specific Embodiment approach 2

[0013] Specific implementation mode two: as image 3 As shown, in this embodiment, 3 to 6 arc-shaped grooves are evenly distributed along the circumferential direction on the outer walls of the upper shell 6 and the lower shell 2, and the inner walls of the upper and lower ends of the middle shell 4 are machined along the circumferential direction. There are protrusions corresponding to the arc grooves. Designed in this way, it is easy to connect and easy to install. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: as Figure 4 As shown, in this embodiment, the flap 5 and the support beam 9 are seamlessly connected through the single-degree-of-freedom flexible hinge 7 to form a non-detachable whole. With such a design, the support beam 9 is seamlessly connected with the flap 5, which avoids the phenomenon of aftertaste. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com