Method for measuring micron-order depths of pits of component

A technology for measuring components and microns, which is applied in the direction of measuring devices, instruments, and optical devices, etc. It can solve the problems of slow detection speed, inconvenient operation, and high cost, improve accuracy and traceability, and solve blind areas that cannot be measured , the effect of no hidden danger of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

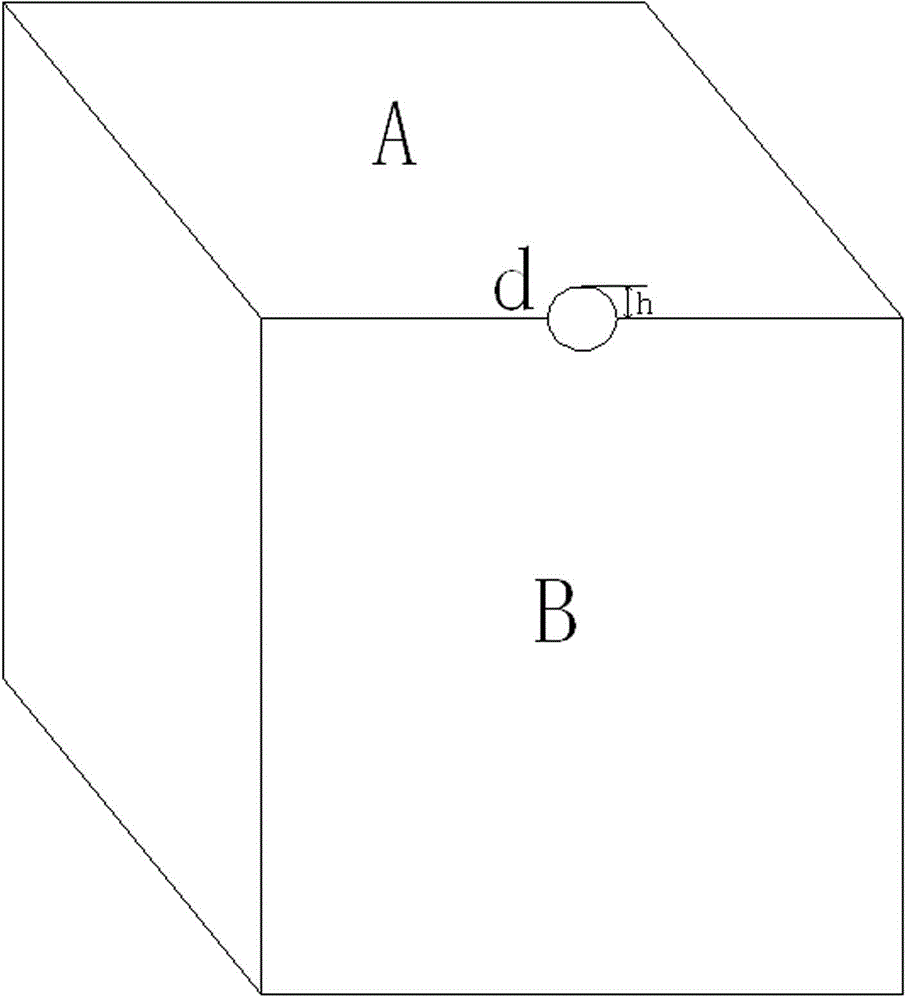

[0036] The characteristics of this embodiment are: according to step 1 and step 2, the depth of part of the concave notch on the standard depth sample block and the corresponding focusing scale difference J 2 -J 1, Step 3. Count the depth of each concave notch on some standard depth samples and the corresponding focusing scale difference J 2 -J 1 , made into the standard depth block scale as shown in Table 2;

[0037] Refer to Table 2 for the scale of standard depth samples

[0038] Focus scale difference / mm 2 3 5 8 Depth / μm 5 8 12 20

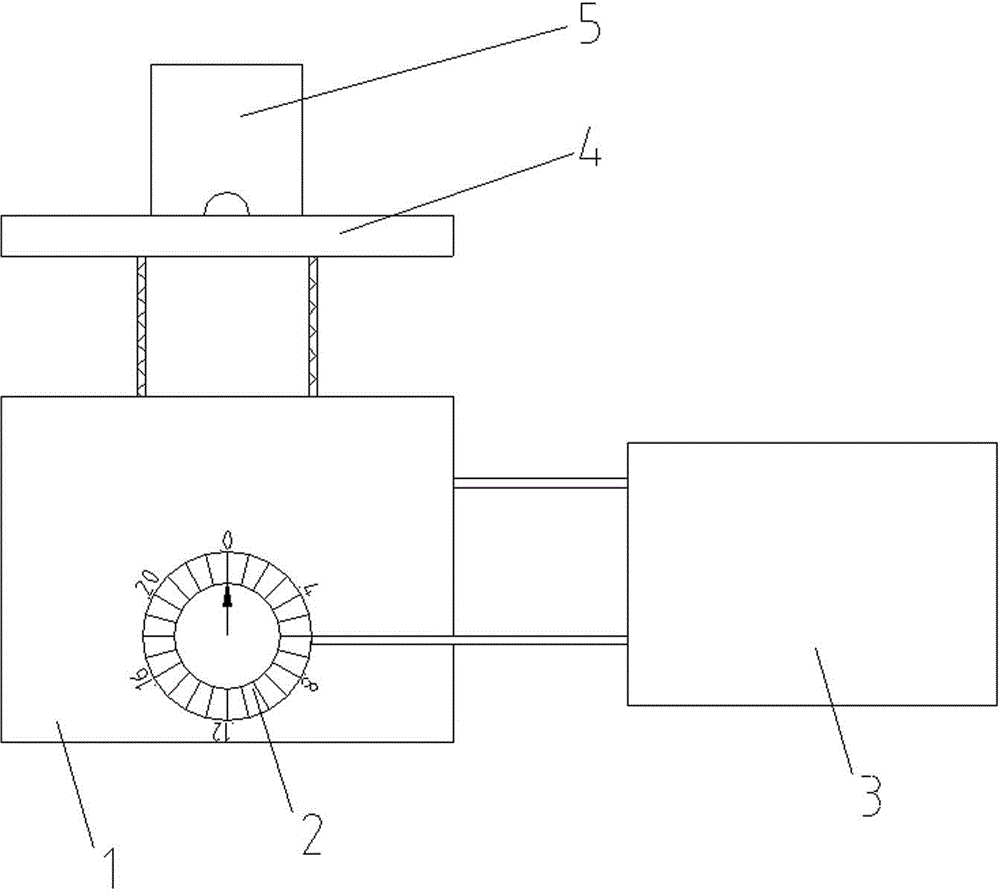

[0039] In step 4, the pit reference plane of the part to be tested is placed on the metallographic microscope 1, and by adjusting the focus knob 2 of the metallographic microscope 1, when the arc outline of the pit reference plane is clear, record the focus knob Focus scale J 1 , and then adjust the focus knob 2 of the metallographic microscope 1 again, when the bottom contour of the pit is as clear as the ar...

specific Embodiment 3

[0040] The characteristics of this embodiment are: the focusing scale J of the focusing knob 2 1 、J 2 Using manual input into the computer, the metallographic microscope 1 measures the horizontal distance h of the concave notch through its own ruler, and manually inputs it into the computer 3 for storage. Other features are the same as those of the specific embodiment 1 and the specific embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com