Precise assembling and adjusting device and method for detector chip of imaging system

A technology of detector chip and imaging system, which is applied in measurement devices, instruments, optical devices, etc., to achieve the effect of easy automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

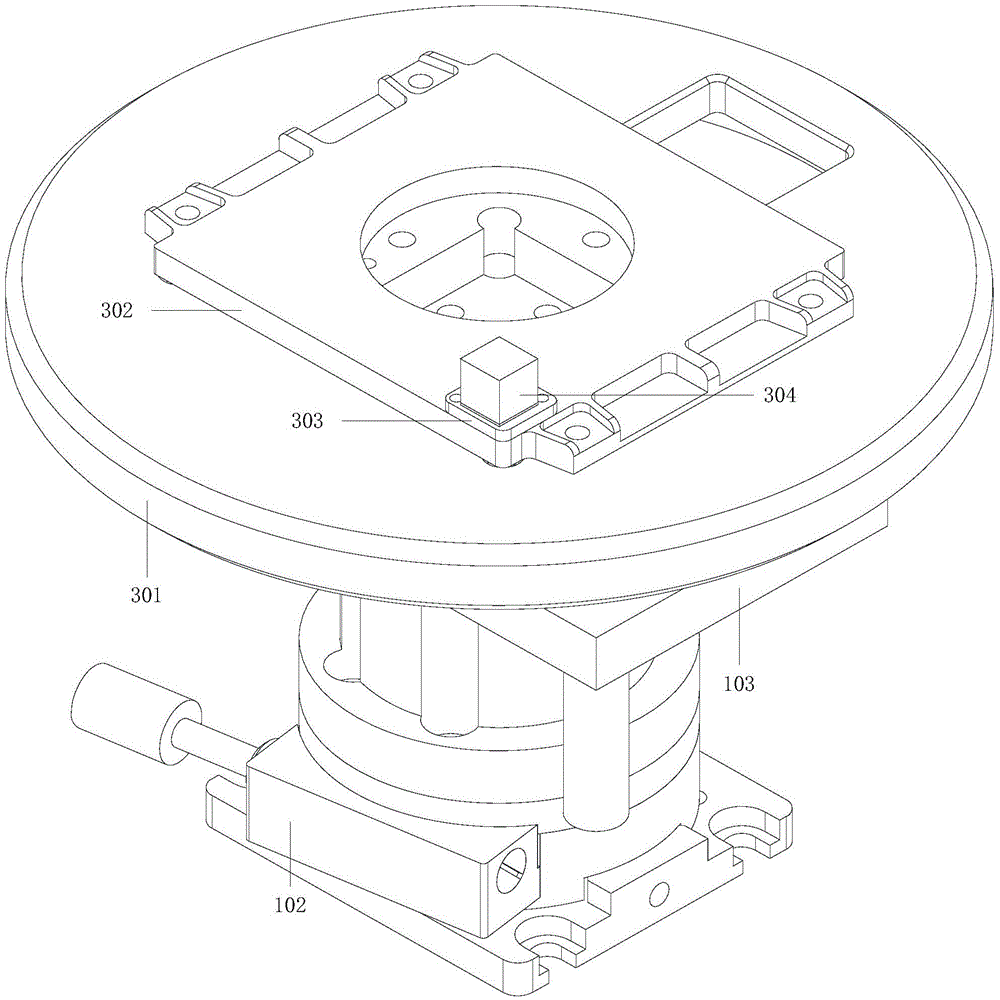

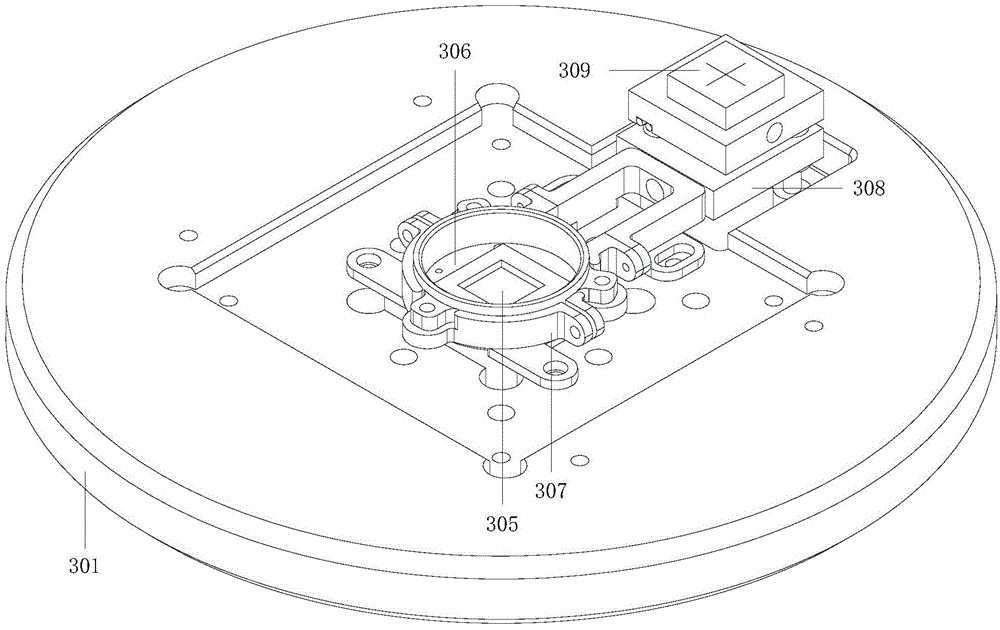

[0073] The imaging system to be assembled and adjusted of the present invention includes a main structure 302, a reference mirror base 303, a reference mirror 304, a detector chip 305, a chip mounting flange 306 and an optical lens 310, and the reference mirror 304 is glued on the reference mirror base 303 , the reference mirror base 303 and the optical lens 310 are installed on the main structure 302 , and the detector chip 305 is installed on the rear end of the optical lens 310 through the chip mounting flange 306 .

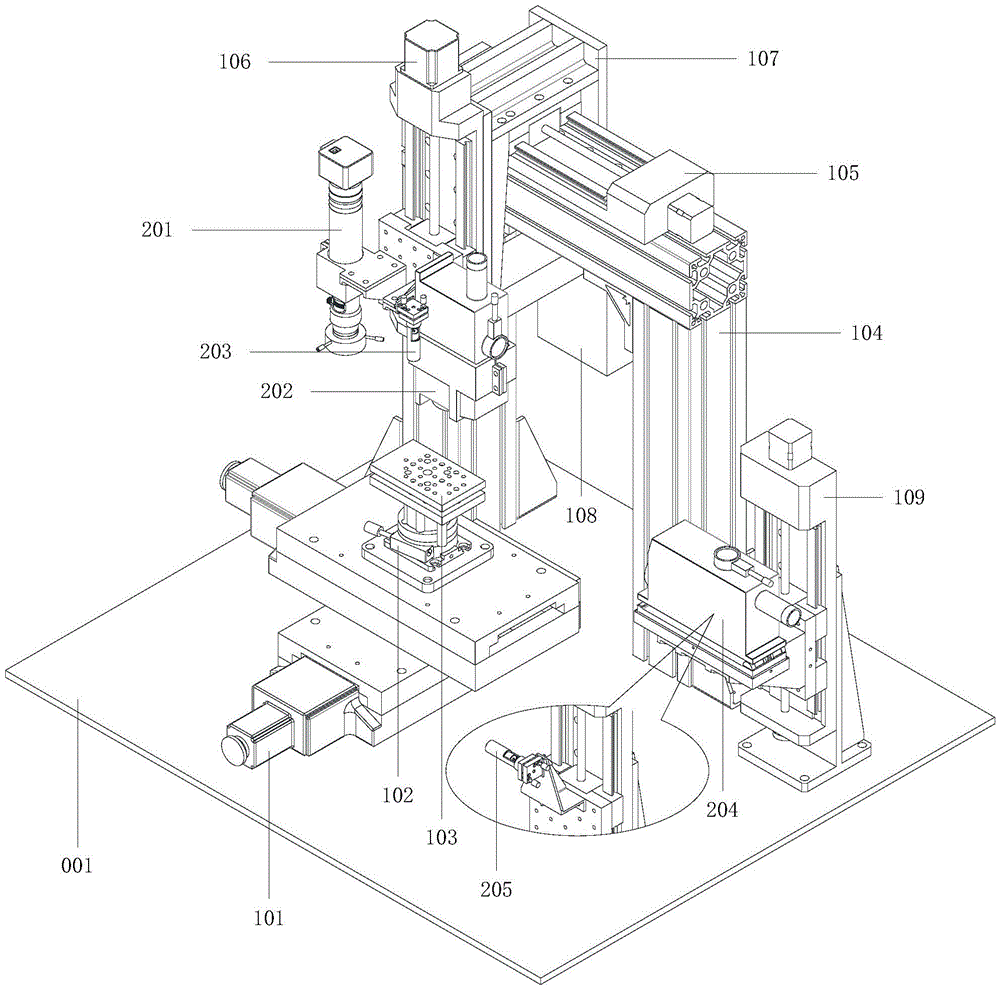

[0074] Such as figure 1 As shown, the imaging system detector chip precision assembly equipment of the present invention includes a motion control system, a detection system, an auxiliary structure and a computer.

[0075] The motion control system is fixed on the optical table 001 and is divided into three areas: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com