Auxiliary loading device for bogie frame strength test

A strength test and loading device technology, applied in railway vehicle testing and other directions, can solve the problems of deviation between simulation results and actual conditions, errors in the validity of mechanical data, hidden dangers of design risks, etc., to achieve true and accurate test results, sufficient layout space, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

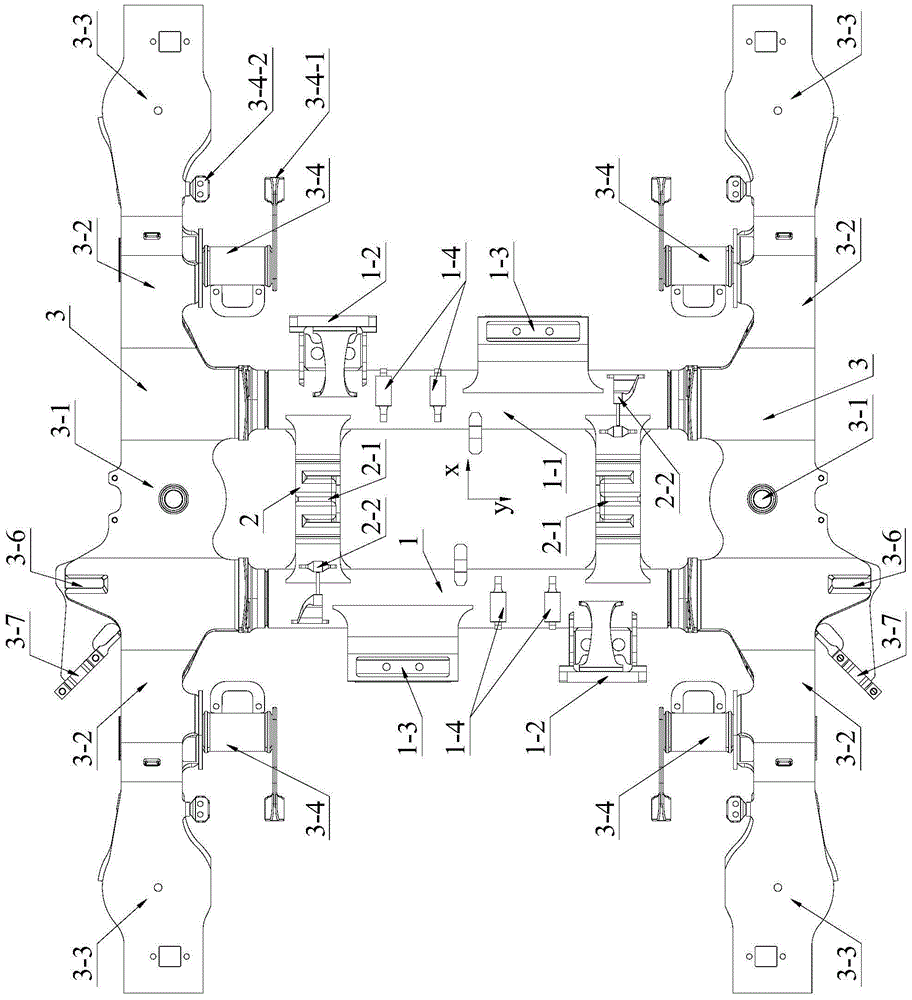

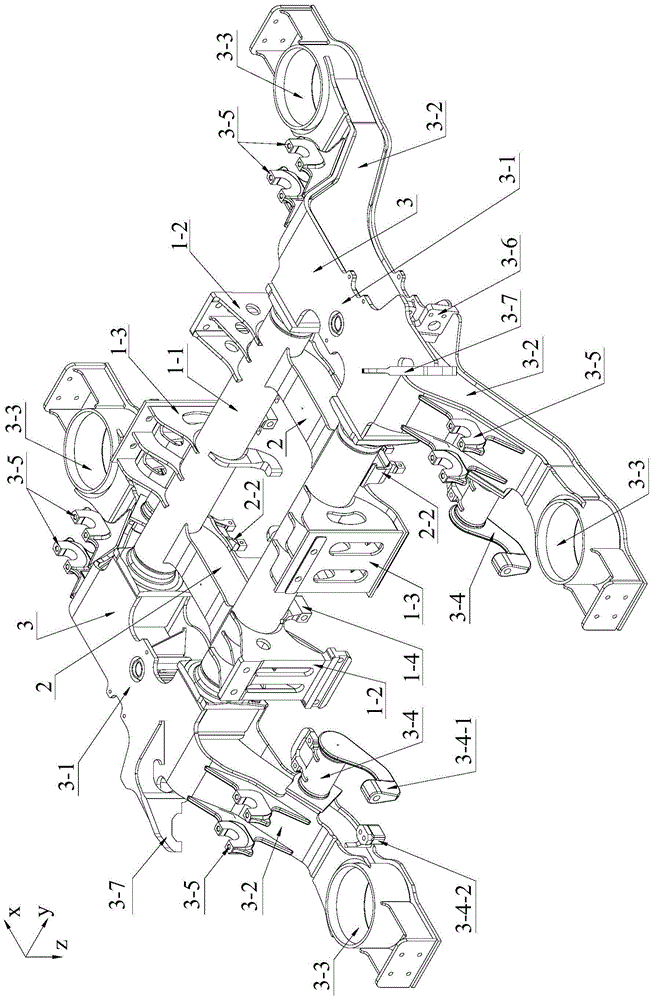

[0045] Such as Figure 4 to Figure 5 As shown, the auxiliary loading device of the bogie frame strength test of the present invention includes four vertical torsional load loading seats 4, two vertical load loading seats 5, two groups of nut spacers 6, lateral load loading devices 7, four Brake load loading seat 8, two anti-serpentine swing load loading seats 9, two gearbox load loading seats 10, two longitudinal load and lateral constraint loading beams 11, two motor load loading seats 12, longitudinal constraint traction seat 13 and two test traction rods 14.

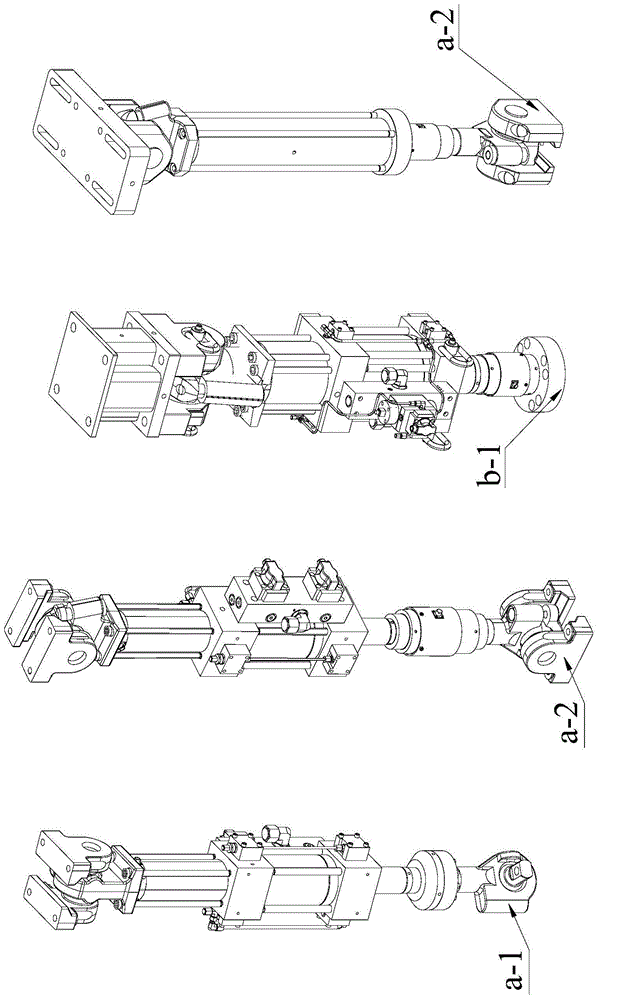

[0046] Such as Image 6 As shown, the vertical torsion load loading seat 4 includes the upper end plate 4-2 of the vertical torsion seat, the lower end plate 4-1 of the vertical torsion seat, the ball head fixing cylinder 4-3, the ball and socket disc 4-4 and four fourth A screw 4-5, a first ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com