Calculating method for fatigue damage coefficient of steel pipe-encased concrete tube-gusset joint

A steel tube concrete, fatigue damage technology, applied in the field of bridge engineering, can solve problems such as fatigue bearing capacity of difficult engineering components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0040] This embodiment provides a method for calculating the fatigue damage coefficient of the concrete-filled steel tube slab joint.

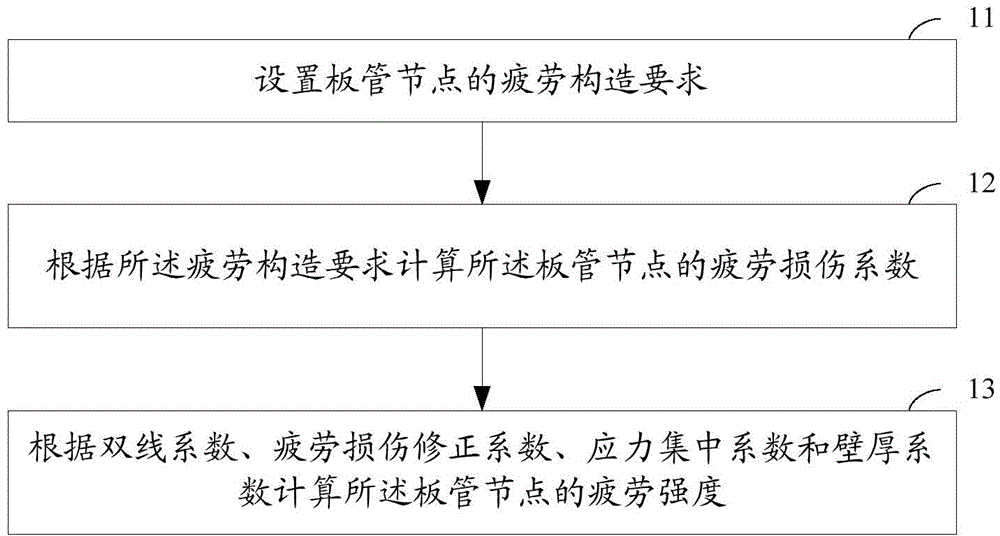

[0041] figure 1 It is a schematic flowchart of the calculation method of the fatigue damage coefficient of the concrete-filled steel tube slab-tube joint in the embodiment of the present invention. Such as figure 1 As shown, the calculation method of the fatigue damage coefficient of the concrete-filled steel pipe slab joint in the embodiment of the present invention mainly includes the following steps:

[0042] Step 11, setting the fatigue structure requirements of the plate-tube joints.

[0043] In the technical solution of the present invention, the fatigue structure requirements of the plate-tube joints can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com