End surface contact type upper specimen clamp capable of automatically leveling

A sample fixture and automatic leveling technology, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of friction and wear test data deviation, and the end-face contact fixture cannot stably hold the sample, so as to improve the accuracy. , The structure is simple, the effect of ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

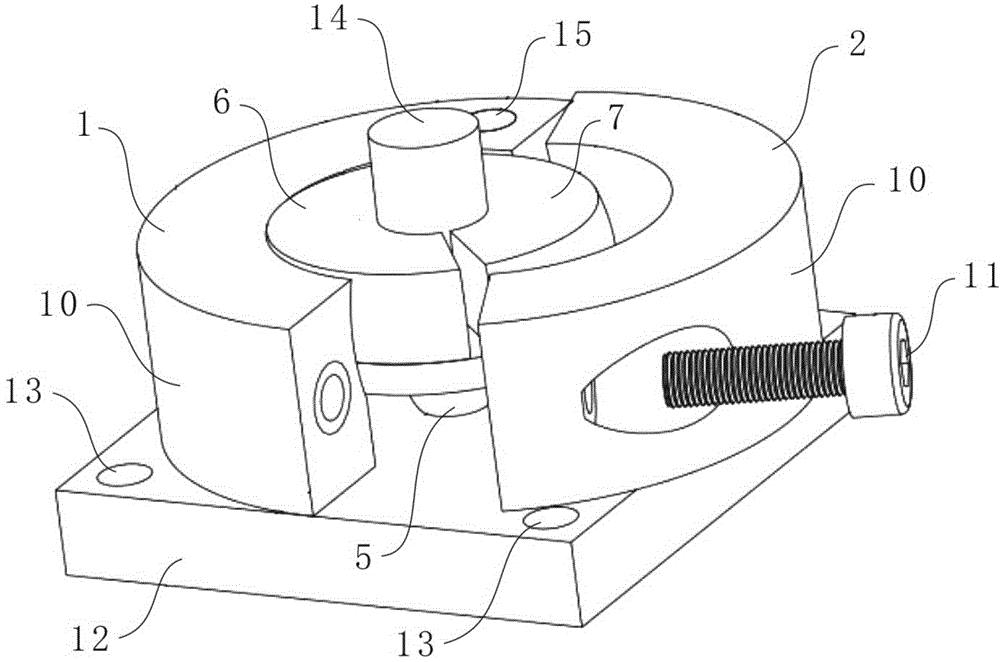

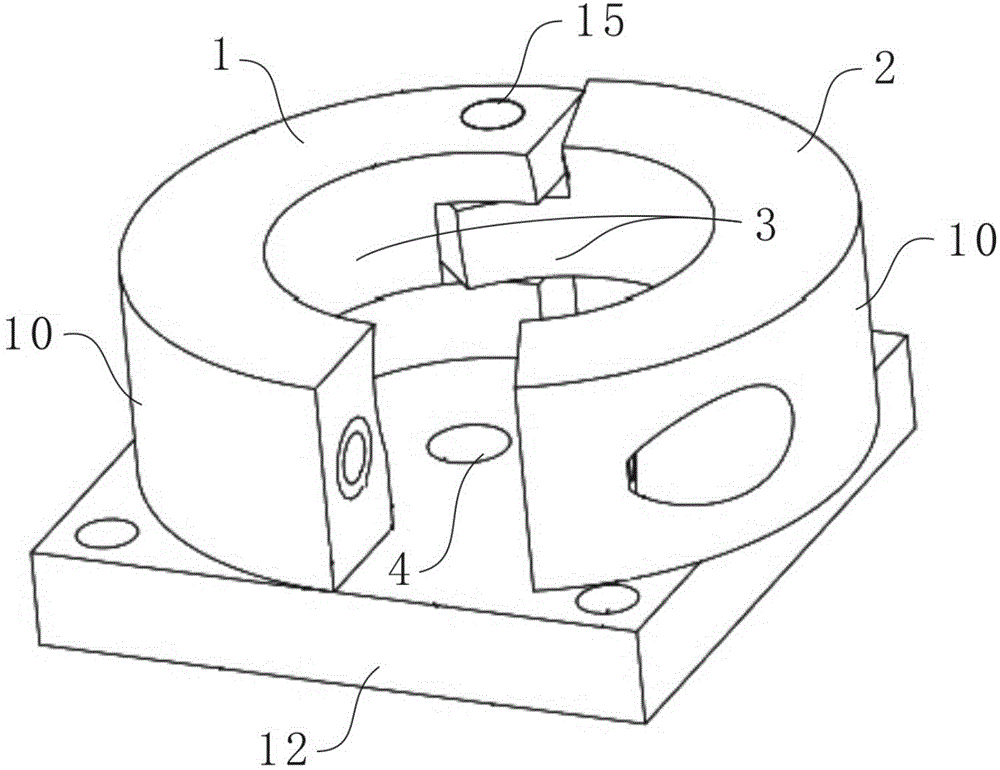

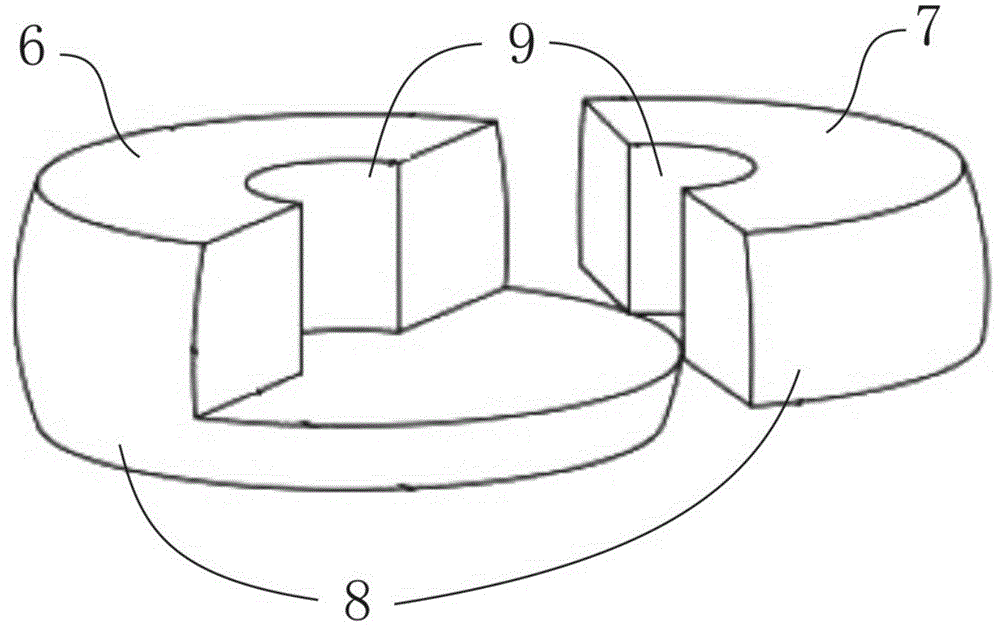

[0026] refer to figure 1 and figure 2 As shown, one embodiment of the present invention is a self-levelling end-face contact type upper sample fixture, including a base 1, which is fixed on a bottom plate 12, and the base 1 is also movably connected with a base platen 2, and more The most important thing is that the inner side of the above-mentioned base body 1 and the base body pressing plate 2 together form a concentric concave spherical surface 3, and on the bottom plate 12, a leveling ball socket 4 and a leveling ball 5 need to be added, and the leveling ball 5 needs to be connected with the leveling ball. The size of the flat ball socket 4 matches and is placed inside the leveling ball socket 4; in addition, combined image 3 As shown, the upper sample clamp in this embodiment is also provided with a clamp body 6 and a clamp pressure plate 7, and the clamp bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com