Hopkinson rod stress wave measurement system and measurement method using flexoelectric effect

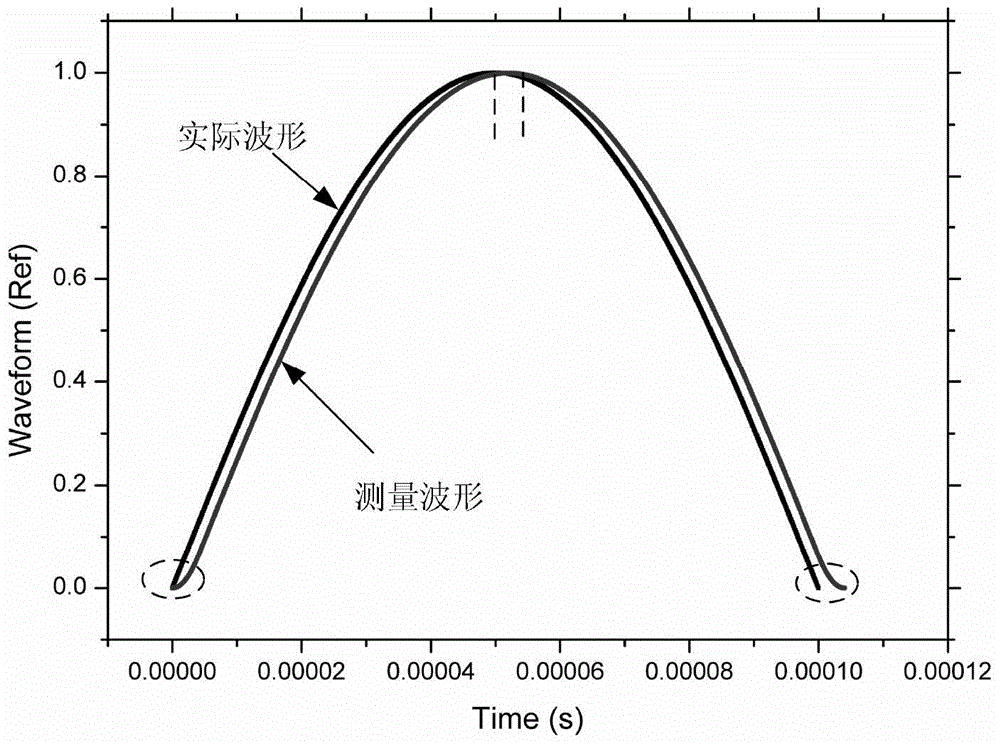

A Hopkinson rod, flexoelectric effect technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of short holding time, waveform distortion, distortion, etc., and achieve accurate measurement of high stress waveforms the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

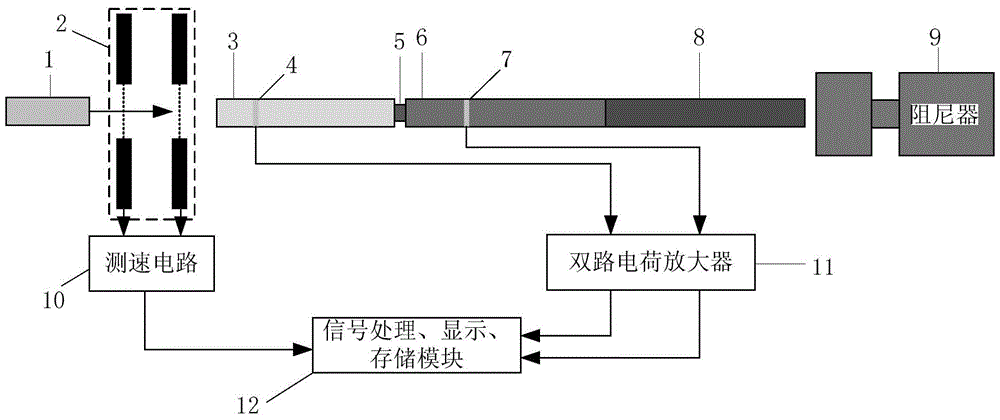

[0032] As shown in the accompanying drawings, the Hopkinson rod stress wave measurement system utilizing the flexoelectric effect of the present invention includes a bullet 1, a laser velocimeter 2, an input rod 3, an output rod 6, an absorption rod 8 and a damper 9, respectively attached to The first strain gradient sensor 4 and the second strain gradient sensor 7 on the input rod 3 and the output rod 6, the velocimetry circuit 10 optically connected to the laser velocimeter 2, and the first strain gradient sensor 4 and the second strain gradient sensor 7 Two-way charge amplifiers 11 electrically connected, wherein the output ends of the speed measuring circuit 10 and the two-way charge amplifiers 11 are electrically connected with the signal processing, display, and storage modules 12; when measuring stress waves, the test piece 5 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com