Test point arrangement method for integrated circuit board

A technology of integrated circuit board and layout method, applied in the direction of electronic circuit testing, etc., can solve the problems of unoptimized processing layout, low precision, irregularity, etc., to facilitate subsequent debugging, improve utilization, and facilitate wiring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

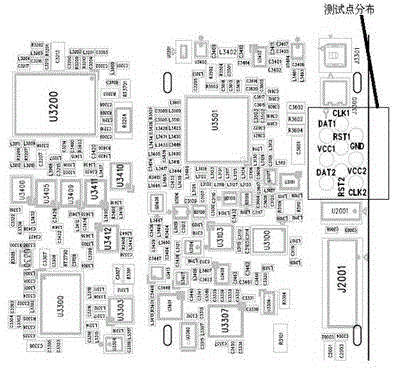

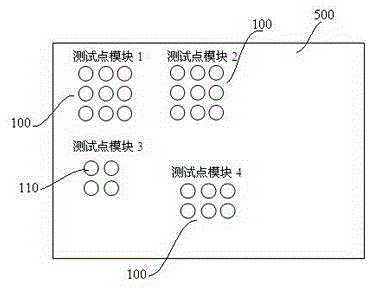

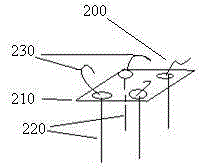

[0054] Such as Figure 2-Figure 6 As shown, a test module for integrated circuit board testing, the test module includes: a plurality of test point modules 100 , a plurality of test pin modules 200 and a plurality of test point combination modules 300 . Wherein, each test point module 100 is distributed and arranged on the integrated circuit board 500 , and the test point module 100 is composed of a plurality of test points 110 with the same function, and the plurality of test points 110 are arranged on the integrated circuit board 500 at equal intervals. Each test pin module 200 is connected to the corresponding test point module 100 for testing.

[0055] Such as figure 2 , Figure 4-Figure 6 As shown, in this embodiment, according to the actual situation of the integrated circuit board 500, the shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com