A photoelectric sensor smart submarine cable

A photoelectric sensing and intelligent technology, applied in the direction of insulated cables, power cables, submarine cables, etc., can solve the problems of impossibility, easy damage, reliability, and tightness cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

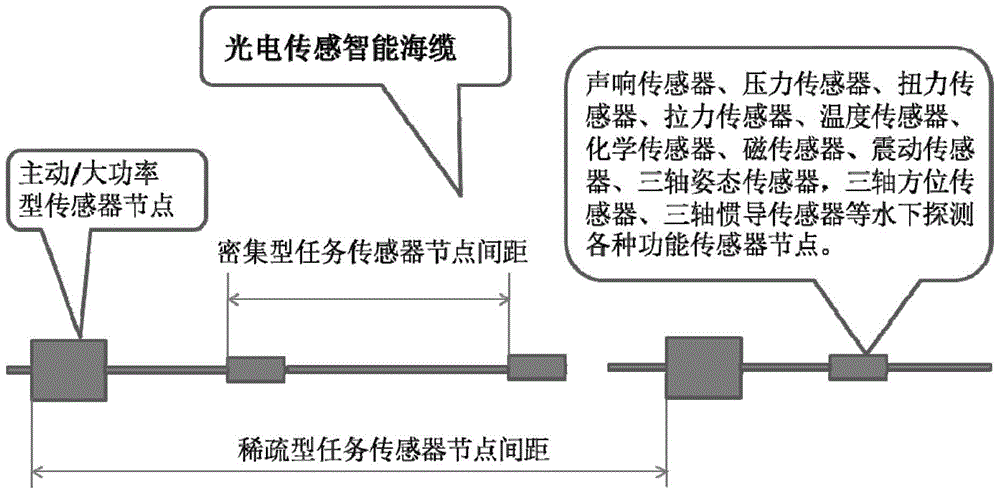

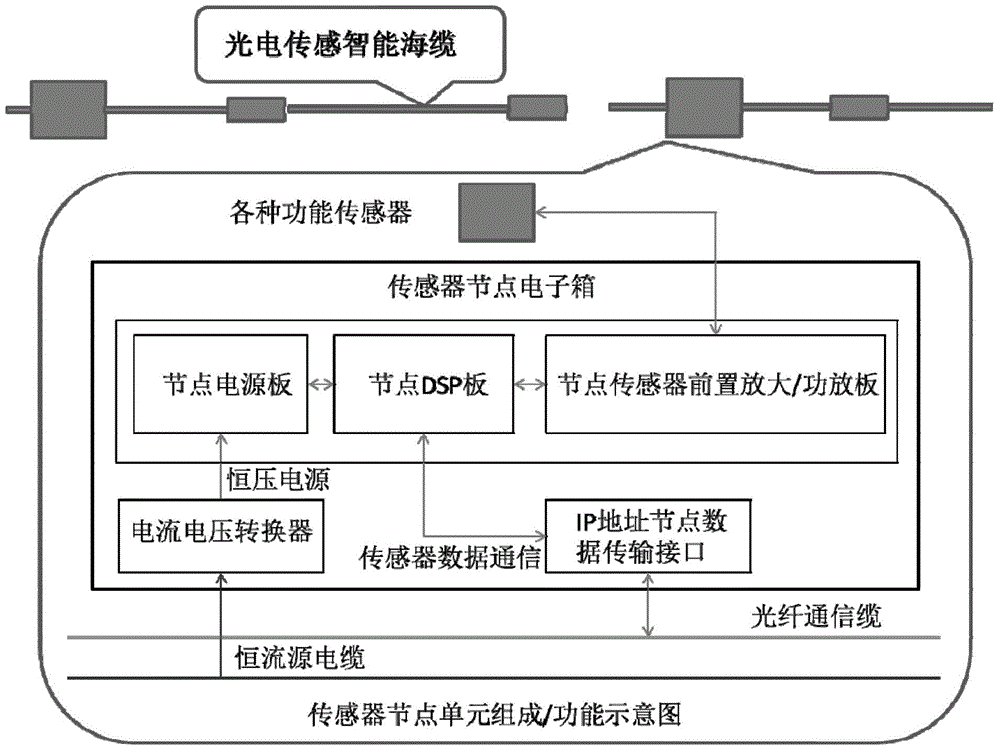

[0033] Such as figure 1 As shown, a photoelectric sensing intelligent submarine cable of the present invention includes a cable and one or more sensor nodes arranged on the cable.

[0034] The sensor node includes a pressure-resistant housing and a sensor installed in the pressure-resistant housing.

[0035] The core wire of the cable has a photoelectric connector in the housing of the sensor node.

[0036] The pressure-resistant casing of the sensor node is connected to the cable through a mechanical connection member.

[0037] The housing of the sensor node has a detachable window for protruding the probe of the sensor out of the housing of the sensor node, and the mechanical connection member can be a stuffing box or a flange with an "O" type The connection structure of the sealing ring.

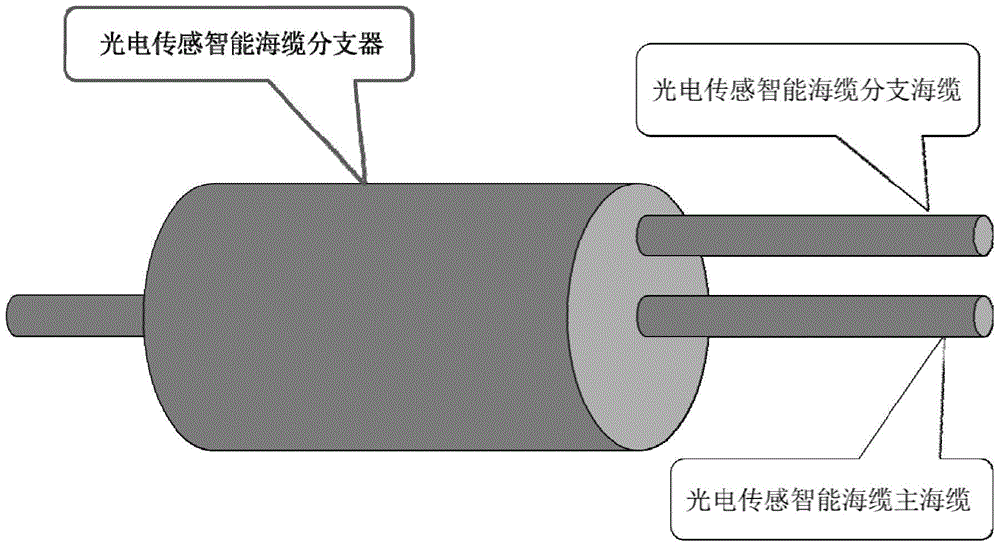

[0038] Such as figure 2 As shown, it also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com