Wafer carrier processing device

A wafer carrying and processing device technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inability to maintain flatness, reduce production qualification rates, and wafer spread, and achieve convenient control and adjustment. Improves production yield and eliminates wafer spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

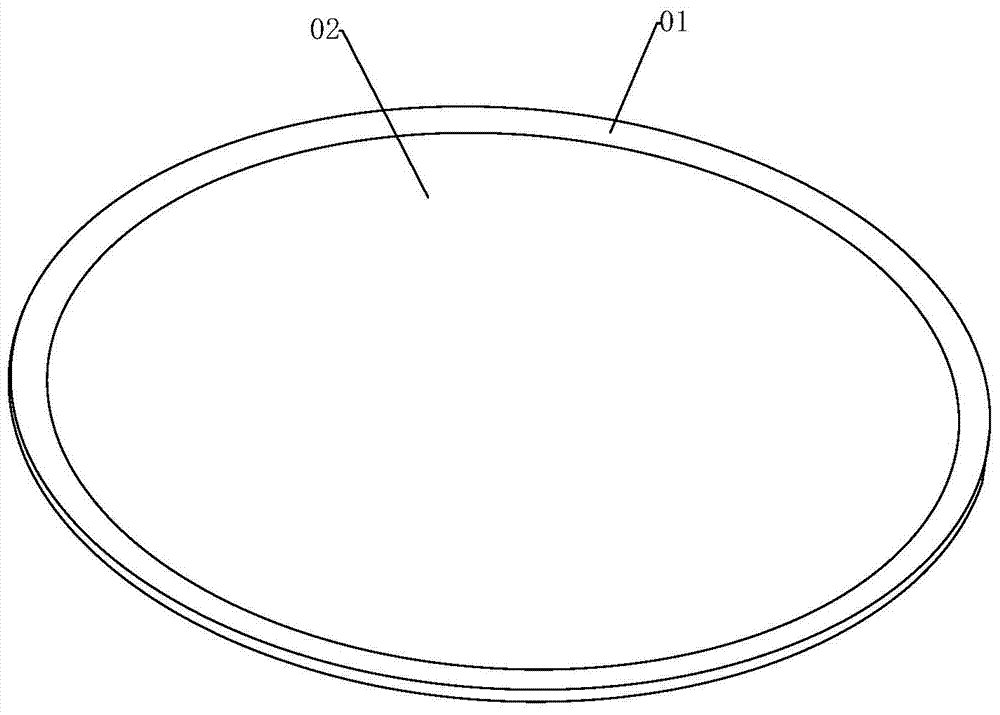

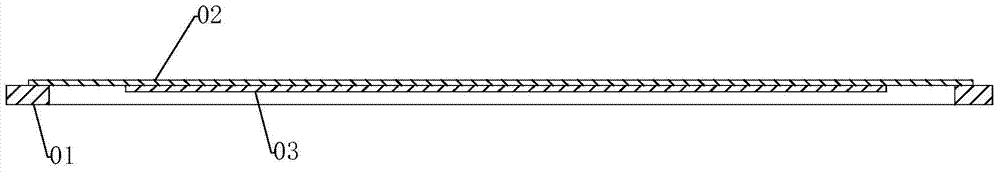

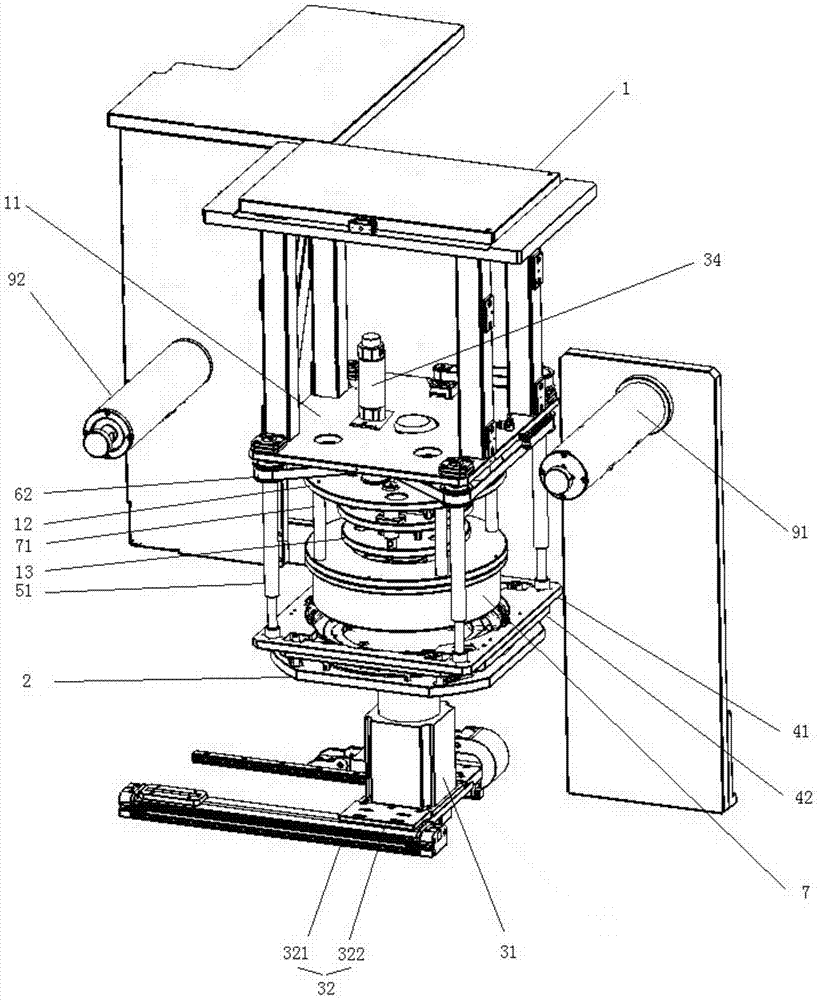

[0040] Such as Figure 4-7 As shown, the processing device of the wafer carrier frame includes a support 1 . The left and right sides of the support 1 are respectively provided with a film releasing device 91 and a film collecting device 92 . The film release device 91 is used to support the film roll and release the film during the rotation of the film roll. The film collecting device 92 is used to collect the leftover film after pasting. A stretch film device is arranged on the bracket 1 . The film passes under the stretcher device, and the stretcher device moves toward the film and then pushes against the film to tighten the film so that the film has tension. A support table 2 for supporting the bandage frame 01 is arranged below the bandage device. The bandage device and the support table 2 can be arranged close to or far away from each other. After the stretch film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com