Climbing type steel wire rope ladder

A steel wire rope and climbing technology, which is applied in the field of tools with secondary protection function, can solve the problems that the upper end of the aluminum alloy hanging ladder cannot be fixed, and the labor intensity and operation risk of high-altitude operators are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

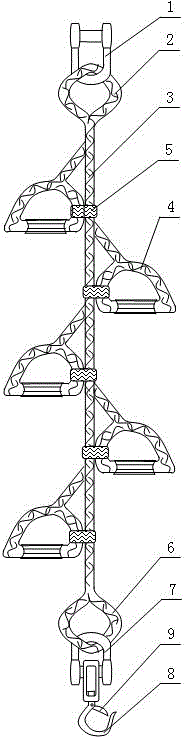

[0017] The climbing type wire rope ladder of the present invention comprises stirrup type pedal 4, rope ladder main wire rope 3 and wire hook 8 etc. The main wire rope 3 of the rope ladder is evenly inserted into a stirrup type pedal 3 every 40cm distance from the upper end to the lower end.

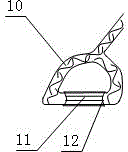

[0018] Stirrup type pedal 4 is inserted on the rope ladder main wire rope 3 by the upper end wire rope of its pedal wire rope cover 10, and pedal steel wire rope cover 10 is wound and fixed on the rope ladder main wire rope 3 by iron binding wire 5. The general 400mm of the circumference of described pedal wire rope cover 10.

[0019] Have upper U-shaped ring 1 on the upper end wire rope cover 2 of rope ladder main wire rope 4, the lower end wire rope cover 7 of rope ladder main wire rope 4 is connected with lead hook 9 by following U-shaped ring 6. The general 300mm of the circumference of described upper end wire rope cover 2, the general 200mm of the circumference of lower end wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com