Corrugated board

A technology for corrugated cardboard and corrugated lining paper, applied in the field of corrugated cardboard, can solve the problems of low strength, poor bearing capacity, easy to break, etc., and achieve the effect of strong bearing capacity, simple production and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

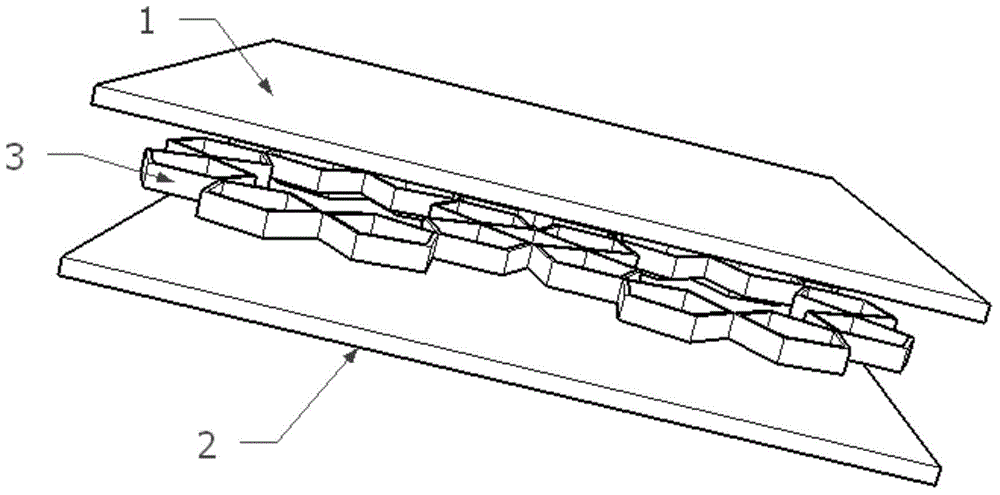

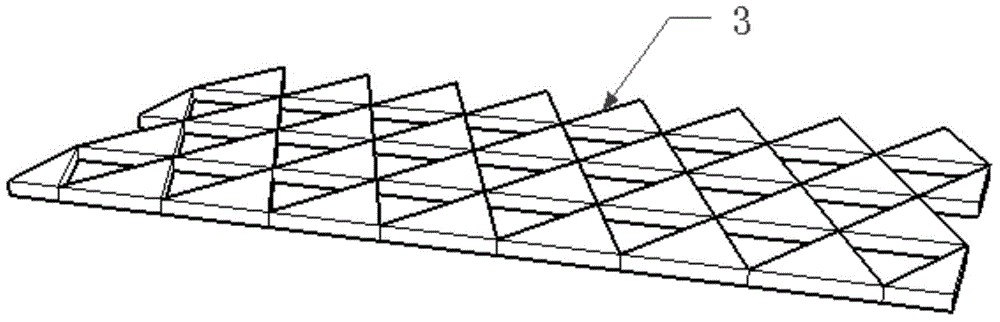

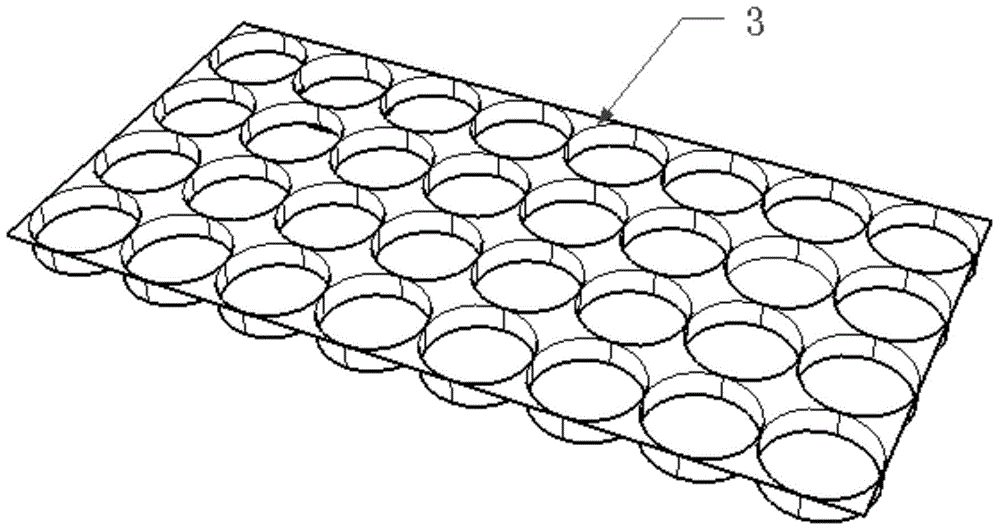

[0014] Such as Figure 1-Figure 3 As shown, the corrugated cardboard of the present invention includes an upper kraft cardboard 1 and a lower kraft cardboard 2, and the space formed between the upper kraft cardboard 1 and the lower kraft cardboard 2 is provided with a net-shaped corrugated backing paper 3, and the net-shaped corrugated backing paper 3 is provided. The corrugated backing paper 3 is supported between the upper kraft cardboard 1 and the lower kraft cardboard 2, the top of the netted corrugated backing paper 3 is fixed on the lower surface of the upper kraft cardboard 1, and the bottom end of the netted corrugated backing paper 3 is fixed On the upper surface of the lower kraft cardboard 2, the grid of the net-like corrugated backing paper 3 is pentagonal, triangular or circular.

[0015] The upper kraft liner 1 and the lower kraft liner 2 are coated kraft linerboard, which makes the finished product have the characteristics of high blast resistance, high tear res...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap