Rail vehicle wheel pair motor direct driving system

A technology for rail vehicles and wheelsets, which is applied in the direction of transmission driven by electric motors, etc., can solve the problems of reduced motor speed, size and weight restrictions, and difficulty in direct drive of asynchronous motors, and achieves improved transmission efficiency and reduced volume and mass. , The effect of energy saving effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

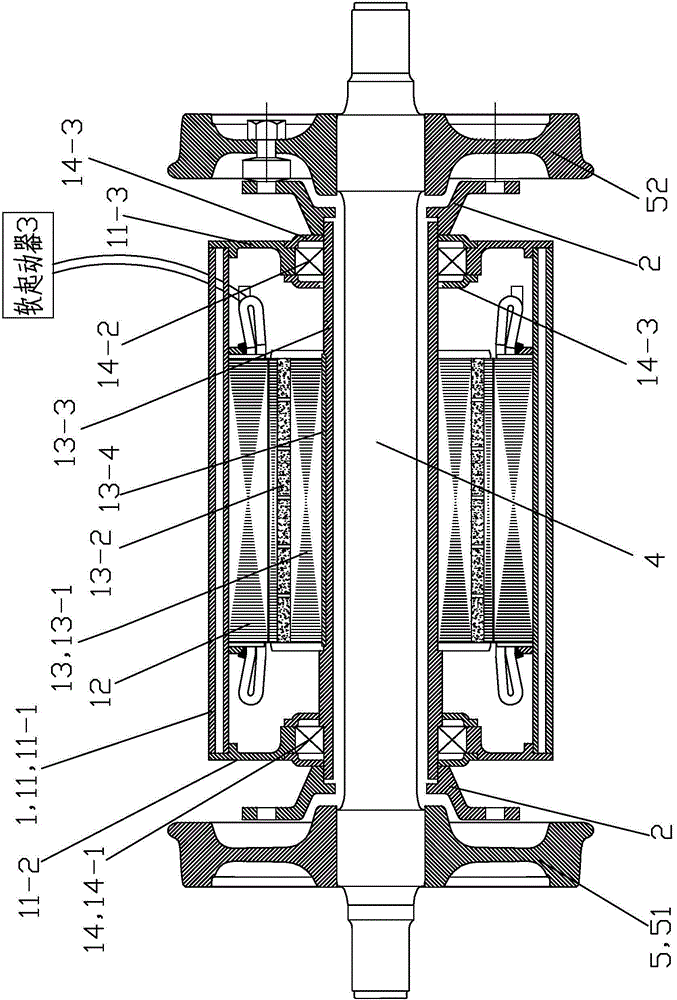

[0028] See figure 1 , The rail vehicle wheel-to-motor direct drive system of this embodiment is mainly composed of a drive motor 1, an elastic coupling 2 and a soft starter 3.

[0029] The driving motor 1 is mainly composed of a casing 11 , a stator 12 , a rotor 13 and a bearing assembly 14 .

[0030] The shell 11 of the drive motor 1 is made up of a support 11-1, a left end cover 11-2 and a right end cover 11-3. The left end cover 11-2 is set on the left side of the machine base 11-1 and is sealed and fixedly connected with the machine base 11-1; the right end cover 11-3 is set on the right side of the machine base 11-1 and is sealed and fixed with the machine base 11-1 connect. The middle of the left end cover 11-2 and the right end cover 11-3 are provided with left and right through circular through holes and inwardly protruding bearing mounts.

[0031] The stator 12 is composed of a stator core and a stator winding. The structure of the stator 12 is basically the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com