Baffle adjusting device of conveyor

A baffle adjustment and conveyor technology, which is applied to conveyors, transportation and packaging, can solve the problems of high production cost, labor and time-consuming, inability to adapt to various specifications at the same time, and achieves the goal of reducing production costs and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below according to the drawings and embodiments.

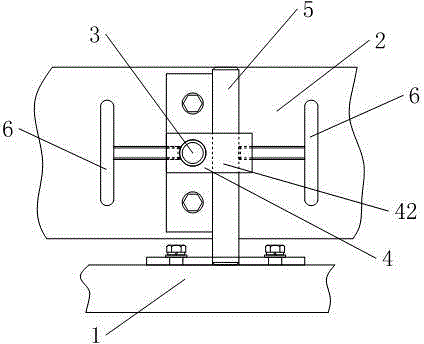

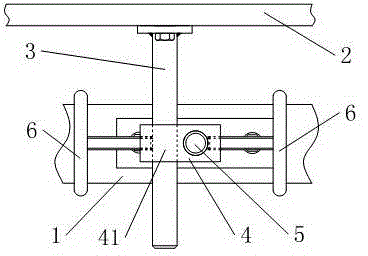

[0012] Such as figure 1 and figure 2 As shown, a conveyor baffle adjustment device according to the embodiment of the present invention includes a frame 1 and a baffle 2, and the outside of the baffle 2 is fixedly connected with a horizontal guide rod 3, and the horizontal guide rod 3 A connection block 4 is connected through the top, and the connection block 4 has a horizontal shaft hole 41 and a vertical shaft hole 42 respectively, and the vertical shaft hole 42 is provided with a vertical guide rod 5 penetrating therein, and the vertical guide rod 5 is fixed on the frame 1, and the horizontal guide rod 3 and the vertical guide rod 5 are respectively fixed on the connecting block 4 by locking screws 6. The horizontal guide rod 3 passes through the horizontal axis hole 41 . The number of locking screws 6 is two, one of which penetrates from the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com