Vibration damper for motor vehicle

A technology for shock absorbers and motor vehicles, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., to achieve the effect of preventing aggregation and increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

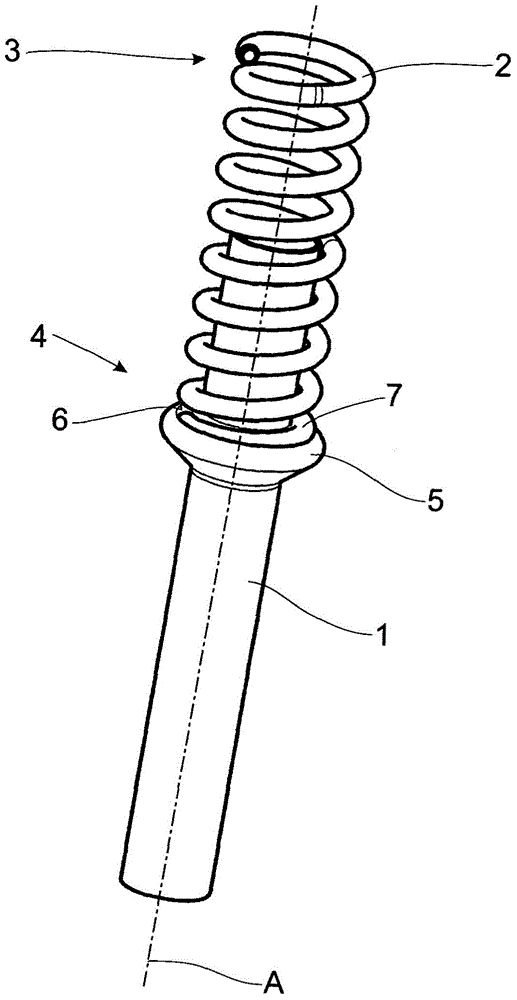

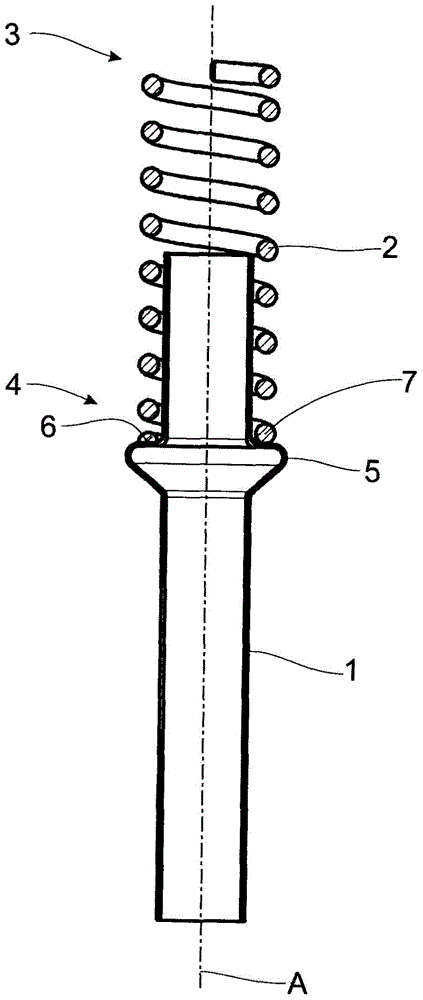

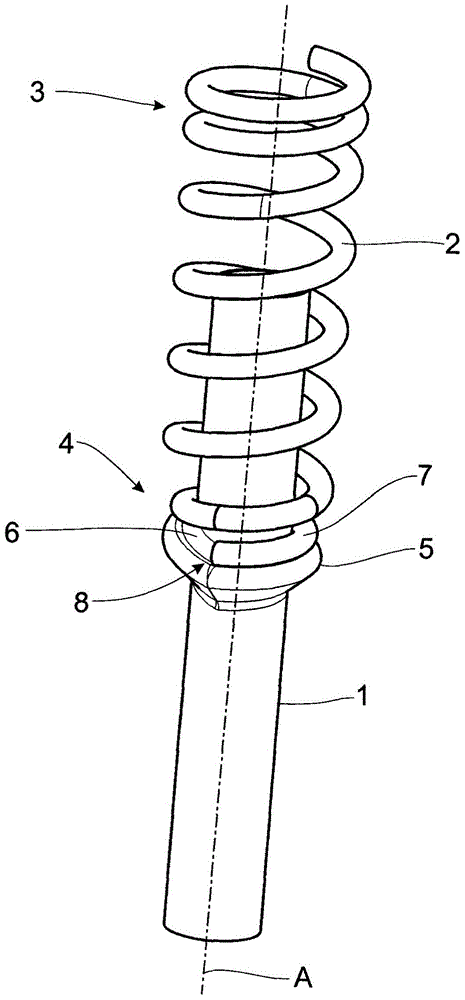

[0029] exist figure 1 shows a cylindrical tube 1 for a shock absorber of a motor vehicle with a longitudinal extension axis A and a carrier spring 2 , wherein the carrier spring 2 surrounds the cylindrical tube 1 in the circumferential direction. The carrier spring 2 has a first end section 3 and a second end section 4 and is supported at least indirectly with the first end section 3 axially relative to the axis of longitudinal extension A of the cylindrical tube 1 (not shown here). on the supporting device of the outgoing motor vehicle. The support spring 2 is supported axially with the second end section 4 on the cylindrical tube 1 of the shock absorber.

[0030] Furthermore, it is shown in all figures that the cylindrical tube 1 has a spring retainer 5 which is formed integrally with the cylindrical tube 1 from the cylindrical tube 1 and which has a support surface 6 for carrying the end coil 7 of the spring 2 . In this case, the spring ring 5 can also be formed out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com