A high temperature resistant drop hammer device for dynamic response transfer characteristic test in thermal environment

A technology with transfer characteristics and high temperature resistance, which is used in measurement devices, strength characteristics, impact testing, etc., and can solve the problem that the dynamic response transfer characteristics test of heating system is not suitable, nylon and rubber materials cannot withstand high temperature, structural form and impact mode are fixed, etc. problems, to achieve the effect of wide range of use, flexible and convenient installation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

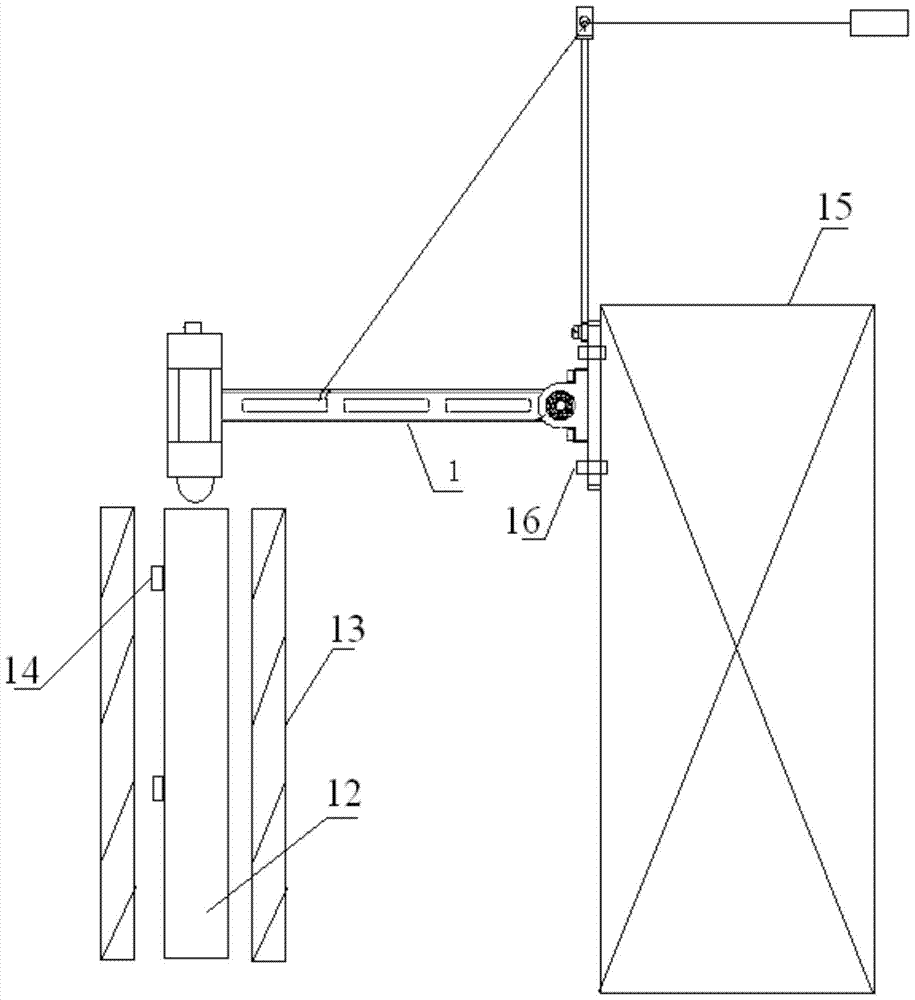

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

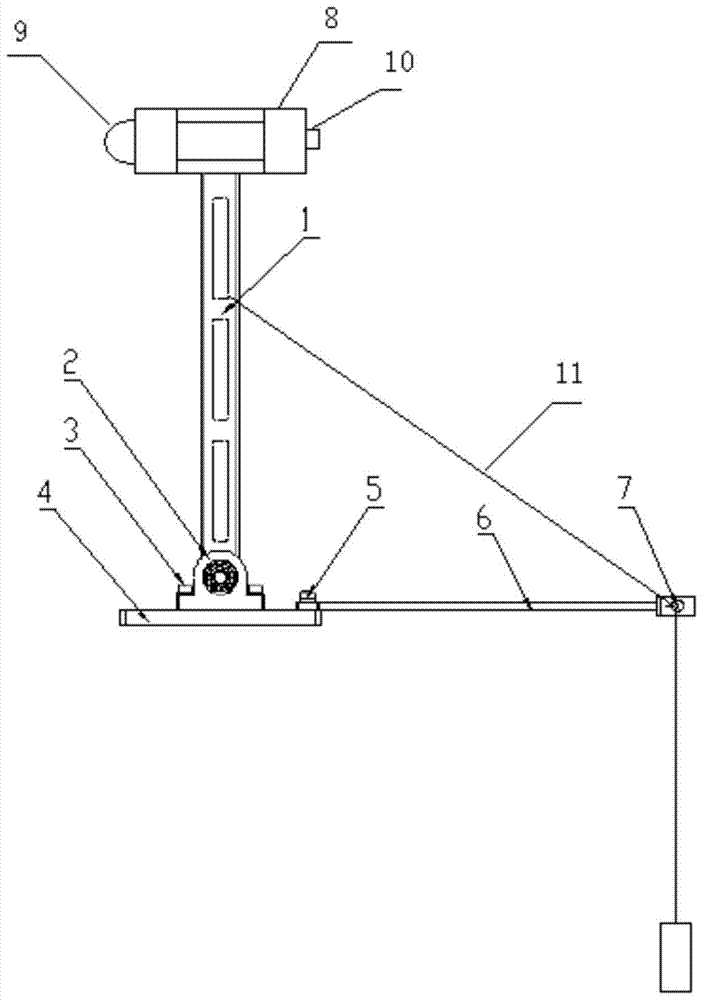

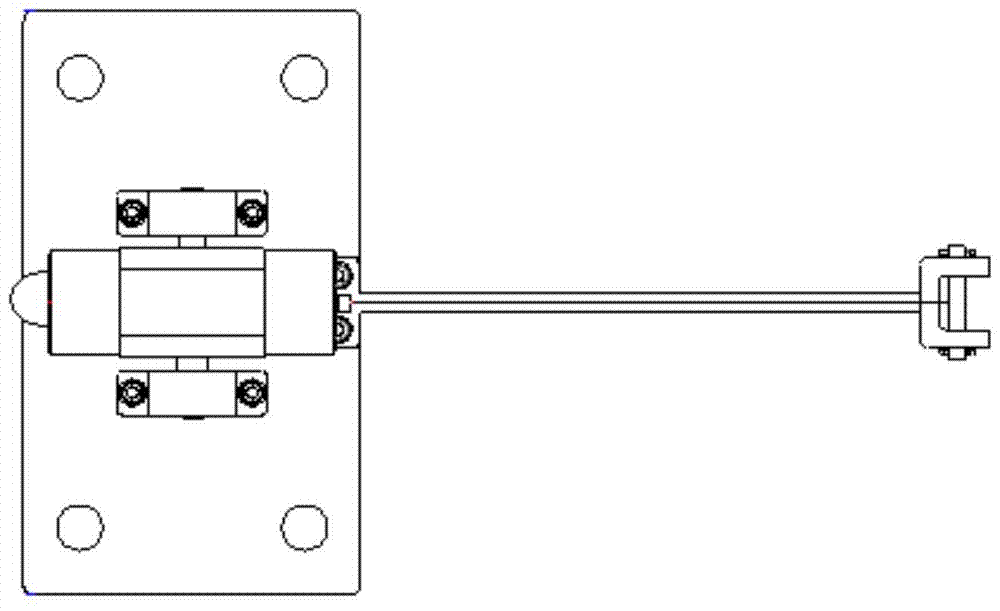

[0028] Such as figure 1 Shown in the present invention is a high temperature resistant drop hammer device for dynamic response transfer characteristic test in thermal environment, including support connecting rod 1, bearing seat 2, hexagon socket head screw 3, mounting plate 4, external hexagon screw 5, remote control Wire support 6, bracket opening 7, hammer head support 8, hammer head 9, first high temperature resistant acceleration sensor 10, remote control line 11.

[0029] The hammer head 9 is connected with the hammer head support 8 through threads, the first high temperature resistant acceleration sensor 10 is connected with the hammer head support 8 through bolts, and the hammer head support 8 is welded together with the upper end of the support connecting rod 1;

[0030] The lower end of the support connecting rod 1 is movably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com