Chip card combination structure and method thereof

A combined structure and chip card technology, which is applied to record carriers, instruments, and electrical components used in machines, can solve the problems of troublesome production, high production costs, and time-consuming, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

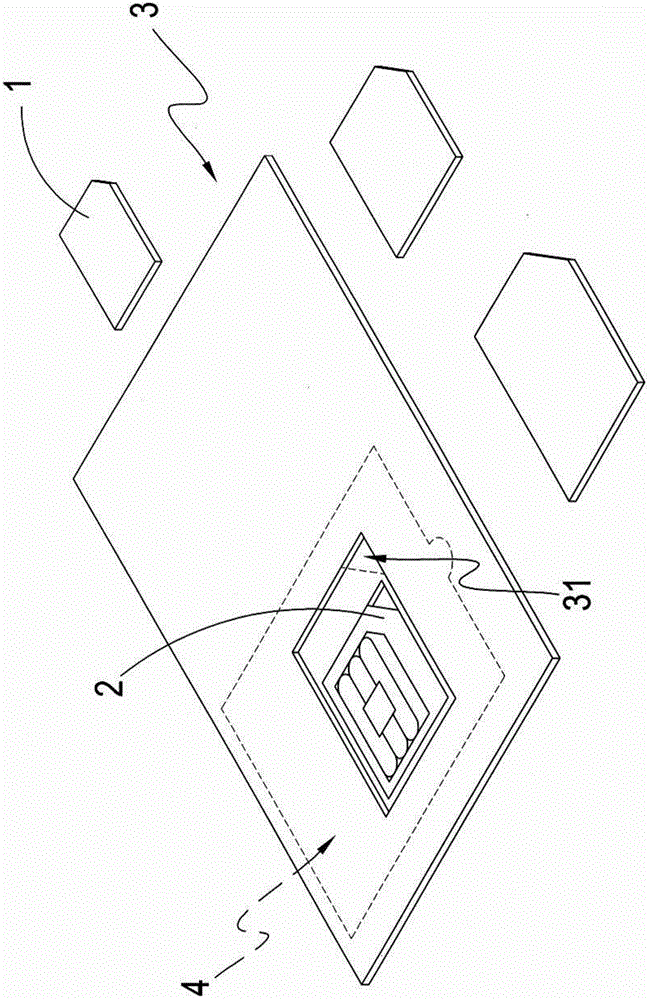

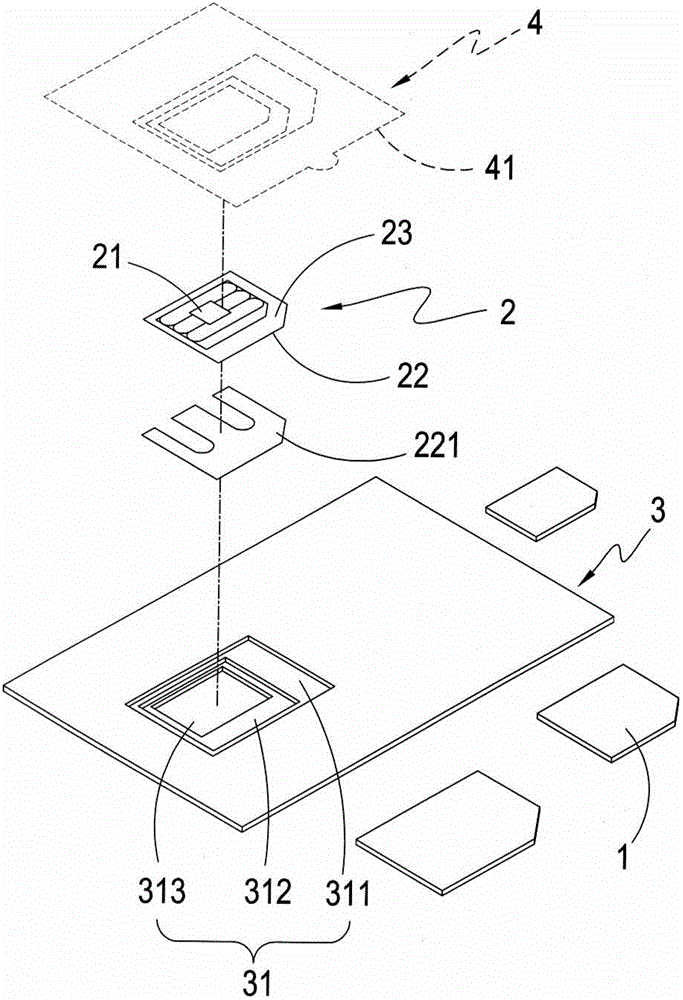

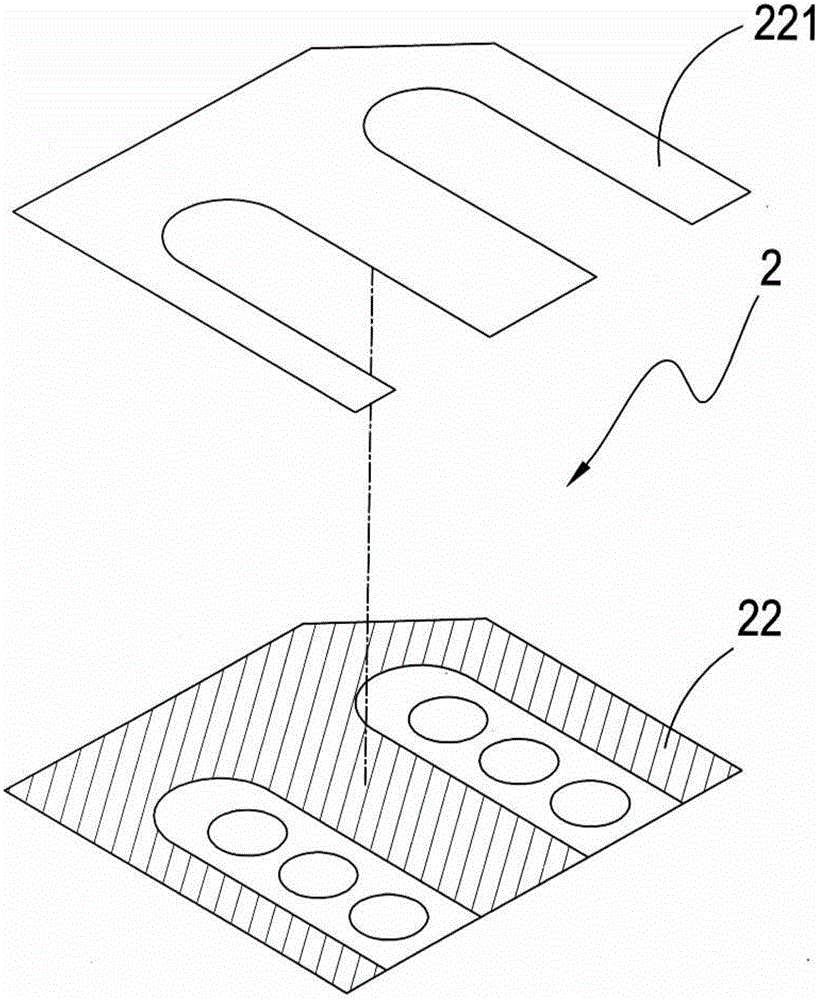

[0033] see Figure 1 to Figure 4 As shown, it is a schematic diagram of the implementation of a preferred embodiment of the present invention, a schematic diagram of separation, a schematic diagram of a thin film wafer and a schematic diagram of a fixed element. It can be clearly seen from the figure that the present invention includes at least one substrate 1, at least one fixed element 3, and at least one adhesive film 4 and at least one thin film chip 2, in this embodiment, three sizes of general SIM card, micro SIM card and nano SIM card are used as illustrations, and at least one side of the fixing element 3 is formed with at least one corresponding to the substrate 1. fixed slot 31, and the fixed slot 31 is further divided into the first fixed slot 311 (the size is equal to the size of a general SIM card), the second fixed slot 312 (the size is equal to the size of a micro SIM card) and the third fixed slot 313 (the size is equal to the size of a micro SIM card) nano SIM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com