Integral brush and vibration motor having the same

A technology of integral brush and vibration motor, applied in electric components, circuits, current collectors, etc., can solve the problem of high cost of flexible board materials, and achieve the effects of high productivity, reduced manufacturing costs, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

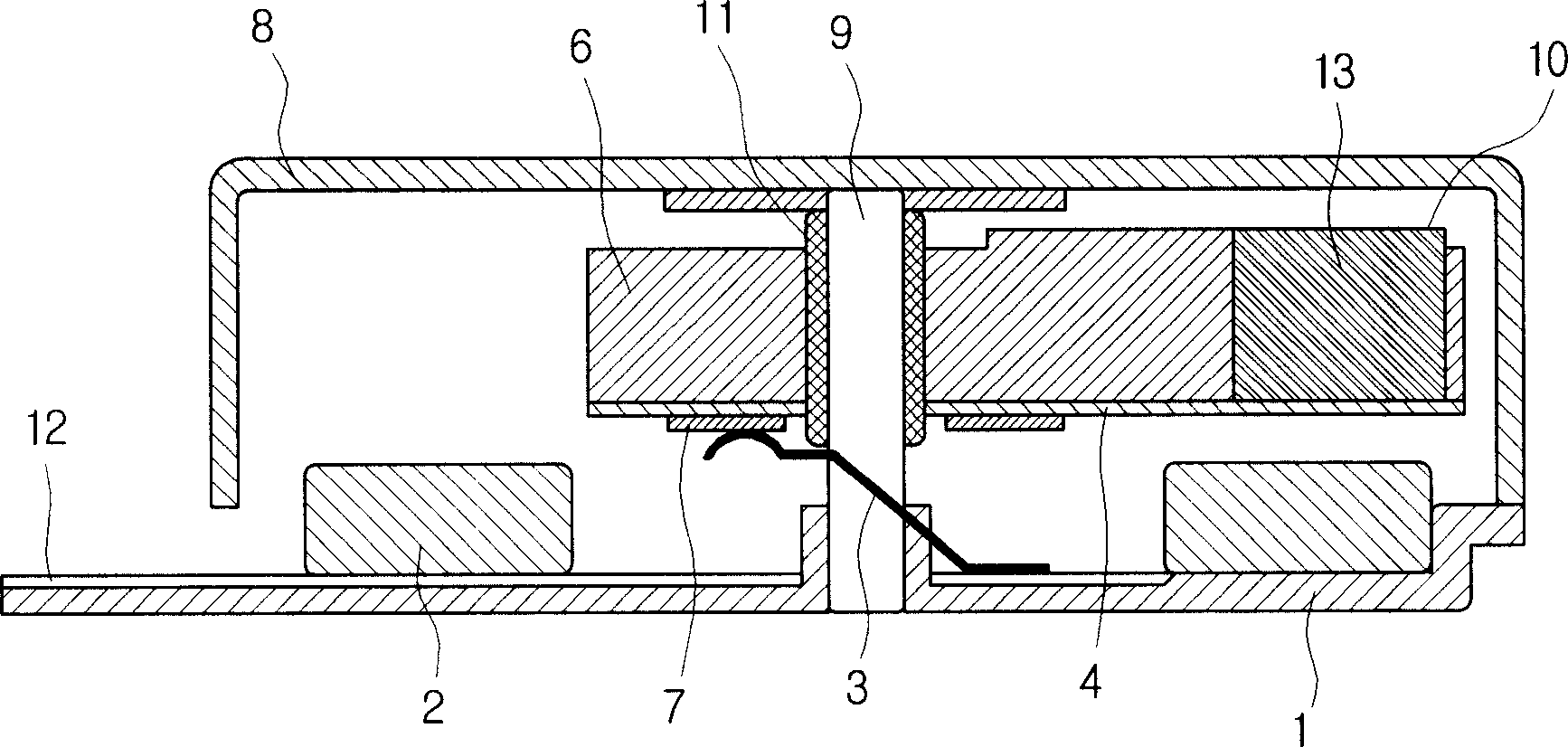

[0034] The preferred embodiments of the integral brush and the vibration motor with the brush according to the present invention will be described in detail below with reference to the accompanying drawings.

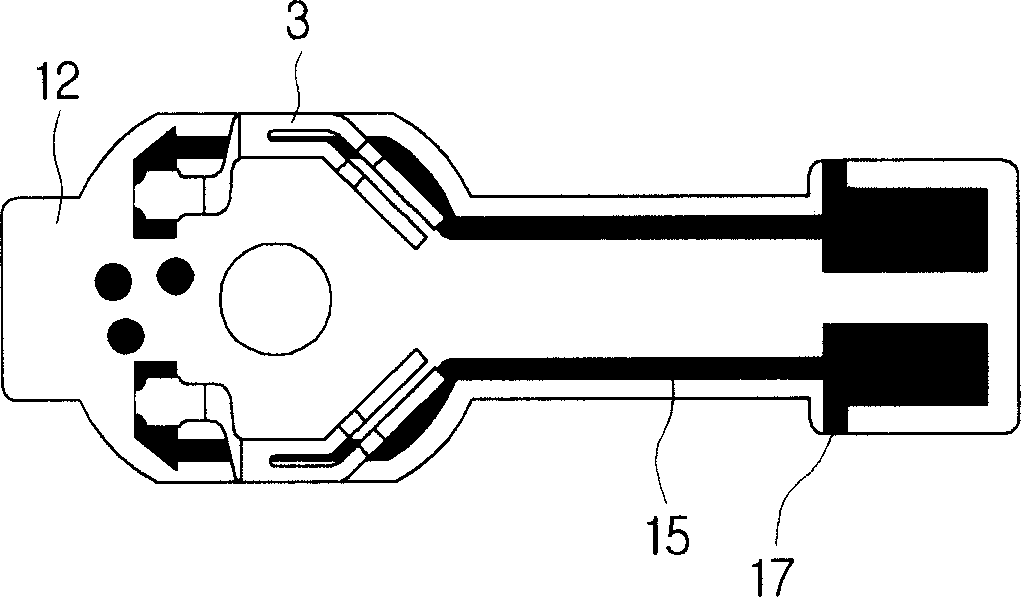

[0035] Figure 4 is a plan view of a brush according to an embodiment of the present invention, and Figure 5 yes Figure 4 Cross-sectional view of the structure. Such as Figure 4 and 5 As shown, a brush 30 according to an embodiment of the present invention includes an arm 31 and an extension 33 extending from the arm 31 .

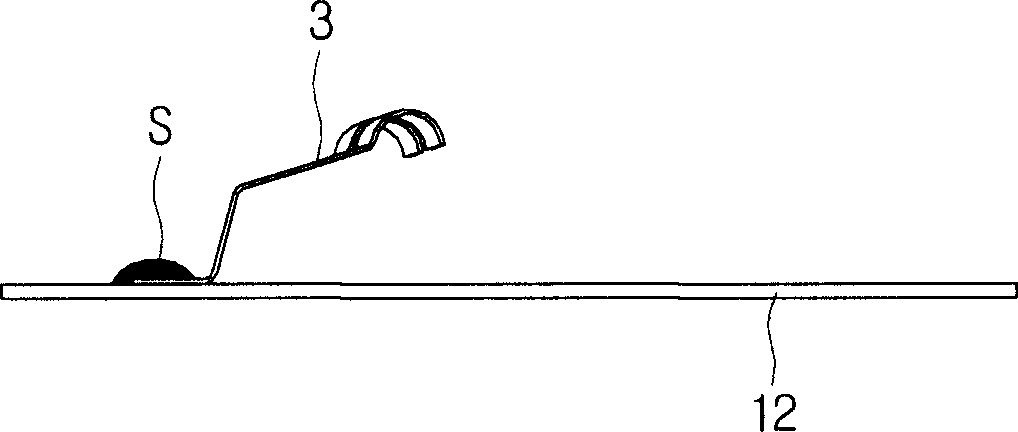

[0036] arm 31, such as Figure 4 As shown, it has an inwardly curved shape. At one end of the arm 31, as Figure 5 As shown, there is an arc-shaped contact portion 31a. Contact portion 31a, such as Figure 6 As shown, it is in contact with the lower surface of the commutator 75 .

[0037] The arm 31 may comprise a plurality of segments 31b, 31c. Therefore, even if one segment is not in contact with the commutator, the other segment is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com