Recyclable centralized-feeding duck forced-feeding device

A technology of equipment and feeding, applied in the application, poultry industry, animal husbandry and other directions, can solve the problems of wasting energy, easy fatigue of operators, waste of feed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

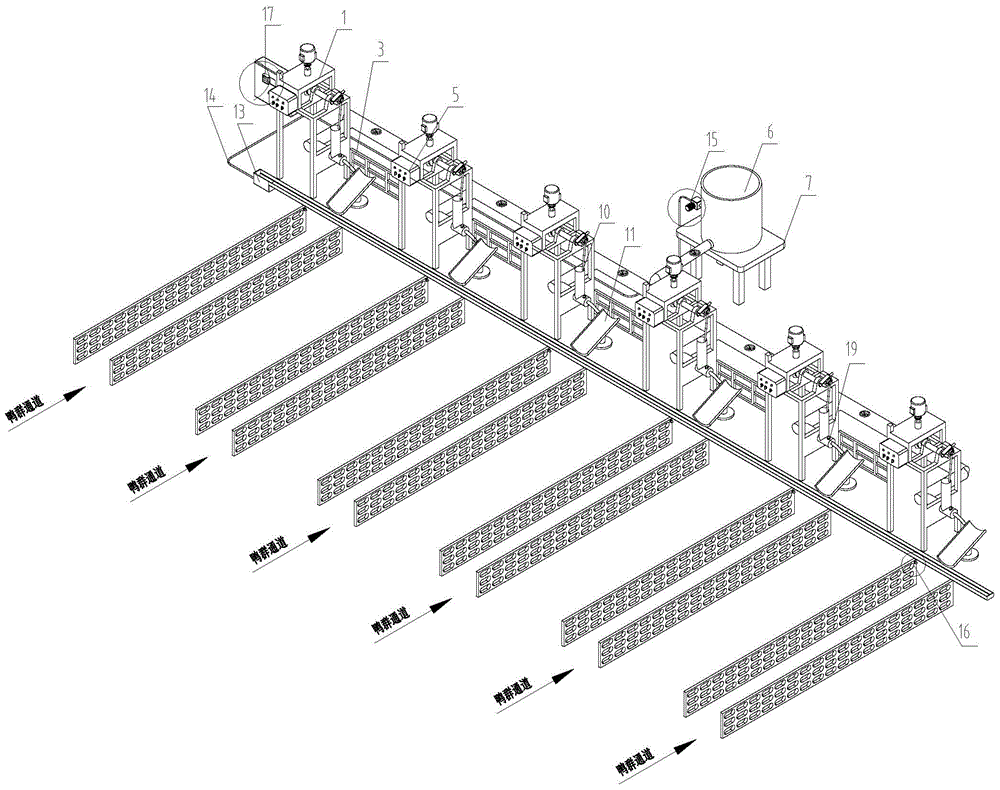

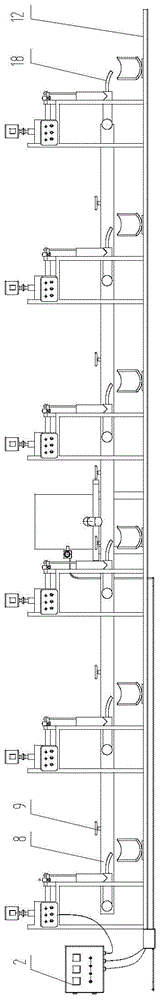

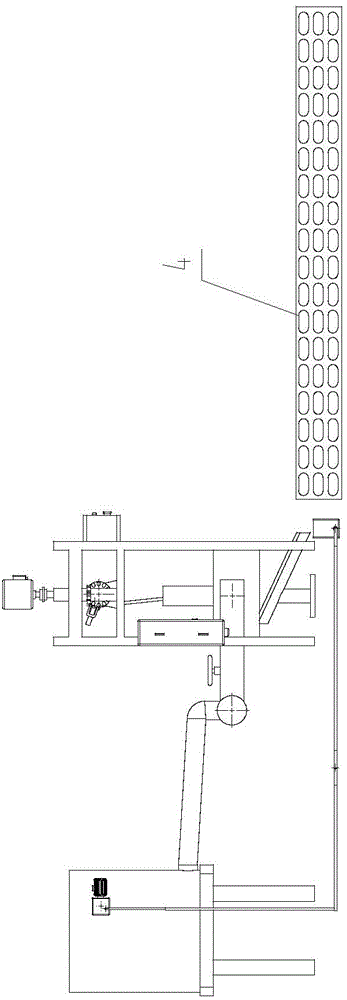

[0022] Embodiment 1 of the present invention: a recyclable duck-feeding equipment for centralized feeding, including a duck-feeding machine 1 and a circuit control device 2, two or more duck-feeding machines 1 and plastic partition columns a3 are arranged in a row at intervals, and the plastic partition columns a3 and duck-cracker 1 divide the space into two areas, one side of the area is provided with two plastic partition columns b4, two plastic partition columns b4 form a walking passage, and one end of the plastic partition column b4 is provided with an infrared induction counter 16, which is located on the side of the area The other side is provided with a centralized feeding cylinder 6, a hydraulic pump 15 is provided on the centralized feeding cylinder 6, an electronically controlled throttle valve 19 and a filling and feeding pipe 18 are provided on the extruding cylinder 10, and the circuit control device 2 is provided with a circulation type The electronic relay 17, t...

Embodiment 2

[0023] Embodiment 2 of the present invention: a recyclable duck-feeding equipment for centralized feeding, including a duck-feeding machine 1 and a circuit control device 2, two or more duck-feeding machines 1 and barbed wire partitions a3 are arranged in a row at intervals, and the barbed wire partitions are arranged in a row a3 and the duck-feeding machine 1 divide the space into two areas, one side of the area is provided with two barbed wire partition columns b4, and the two barbed wire partition columns b4 form a walking passage, and one end of the barbed wire partition column b4 is provided with an infrared sensor counter 16. The other side is provided with a centralized feeding cylinder 6, a hydraulic pump 15 is provided on the centralized feeding cylinder 6, an electronically controlled throttle valve 19 and a filling and feeding pipe 18 are provided on the extruding cylinder 10, and the circuit control device 2 is provided with a circulation type The electronic relay 1...

Embodiment 3

[0024]Embodiment 3 of the present invention: a recyclable duck-feeding equipment for centralized feeding, including a duck-feeding machine 1 and a circuit control device 2, two or more duck-feeding machines 1 and a wooden partition bar a3 are arranged in a row at intervals, and the wooden partition bar a3 and duck-cracker 1 divide the space into two areas, one side of the area is provided with two wooden partition columns b4, two wooden partition columns b4 form a walking passage, and one end of the wooden partition column b4 is provided with an infrared sensor counter 16, which is located on the side of the area. The other side is provided with a centralized feeding cylinder 6, a hydraulic pump 15 is provided on the centralized feeding cylinder 6, an electronically controlled throttle valve 19 and a filling and feeding pipe 18 are provided on the extruding cylinder 10, and the circuit control device 2 is provided with a circulation type The electronic relay 17, the circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com