Single-pipeline pneumatic bait-feeding device for aquaculture

An aquaculture, single-pipe technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of time lag in feeding, large amount of feed by pneumatic conveying, and inability to exert the advantages of rapidity, so as to improve the application performance of the system, The effect of simplifying equipment system structure and reducing equipment manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

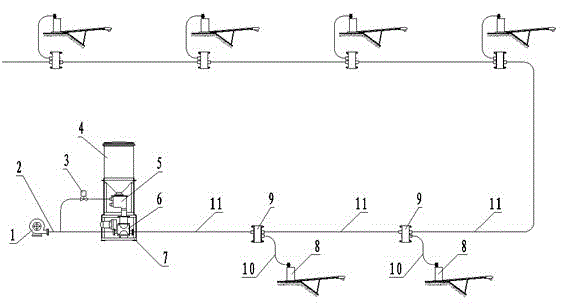

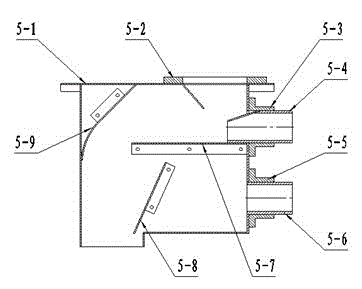

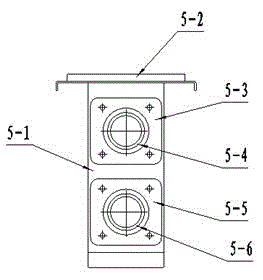

[0060] see Figure 1-Figure 10 , a single-pipeline aquaculture pneumatic bait feeding facility, the facility consists of a fan 1, an air pipe 2, a solenoid valve 3, a feed bin 4, a pneumatic jet feeder 5, an air shutoff device 6, a frame 7, and a feed pneumatic conveying shell The throwing type bait feeding machine 8, the main pipe straight through the slider type spool distributing valve 9, the distributing branch pipe 10 and the feeding main pipe 11 are connected to form;

[0061] Said blower fan 1 communicates with the air shutoff device 6 through the air delivery pipe 2, and a branch pipe is connected in the air delivery pipe 2, and the other end of the branch pipe is connected with the nozzle of the pneumatic jet feeder 5, and an electromagnetic valve 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com