Method for recycling aroma in process of processing oolongs

A technology for aroma recovery and processing, which is applied in the field of aroma recovery in the process of oolong tea processing, to achieve huge commercial value, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

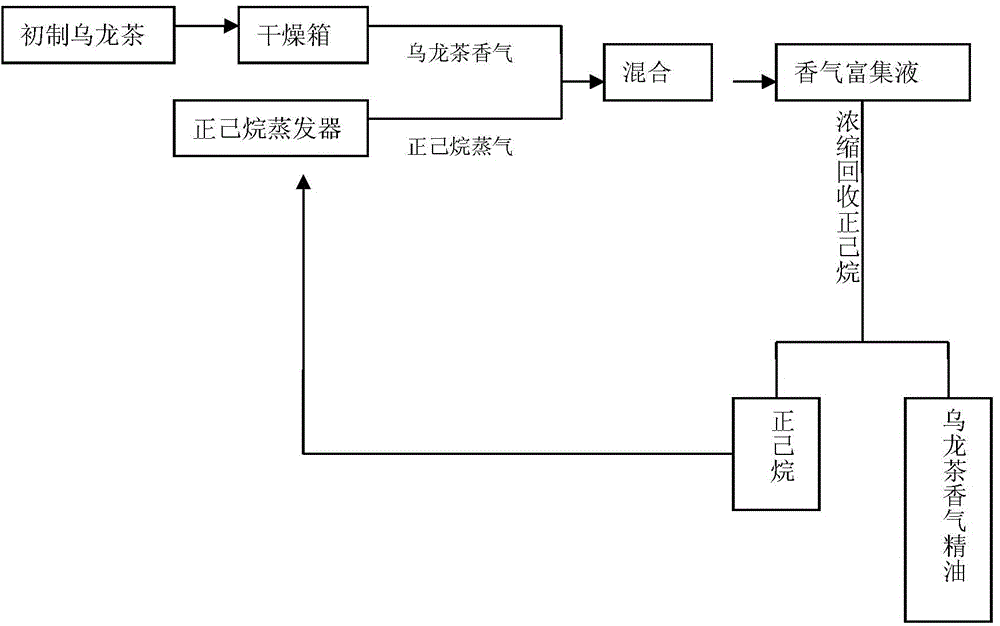

[0019] Such as figure 1 Shown, a kind of aroma recovery method in oolong tea processing, comprises the steps:

[0020] Step 1. Drying: Put the tea leaves that have been greened and twisted into a drying box to dry, and the drying time does not exceed 4 hours;

[0021] Step 2. Enrichment: In the later stage of oolong tea drying, when the water content in the tea leaves is 8%, use a high-pressure blower to pump the hot air in the air generator into the drying box, and heat it to pressurize it to 0.15MPa at a temperature of 80°C -85°C, after standing for 10-15 minutes, fully mix the exhaust port of the drying box with the steam pipe heated by n-hexane in the gas-gas mixer and pass it into the water condenser for condensation to collect n-hexane after absorbing aroma solution, as the drying ends, so does the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com