WVR (wave vapor recompression) continuous vaporization system

A technology of vapor recompression and evaporation system, applied in the direction of multi-effect evaporation, evaporator accessories, etc., to achieve high efficiency, excellent operating performance with liquid, and small structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

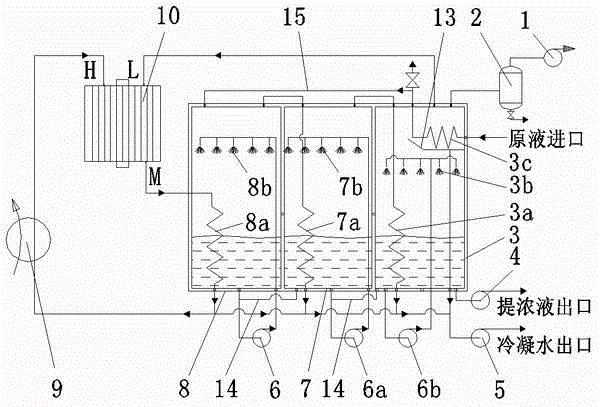

[0018] Example 1 The recompression of the secondary steam is completed in the phase change gas wave supercharger by using the driving steam.

[0019] figure 1 A gas wave vapor recompression continuous evaporation system is shown. In the figure, the gas wave vapor recompression continuous evaporation system includes a three-effect evaporator, concentrated liquid pump 4, condensate water pump 5, steam boiler 9, phase change gas wave supercharger 10 and vacuum pump 1. The three-effect evaporator consists of the first effect An evaporator 8, a secondary effect evaporator 7 and a final effect evaporator 3 are formed, and the bottoms of the first effect evaporator 8 and the secondary effect evaporator 7, and the bottoms of the secondary effect evaporator 7 and the final effect evaporator 3 are connected to each other by a communication pipe 14. The first effect circulation pump 6 of the first effect evaporator 8 is used to connect the first effect liquid uniform distributor 8b...

Embodiment 2

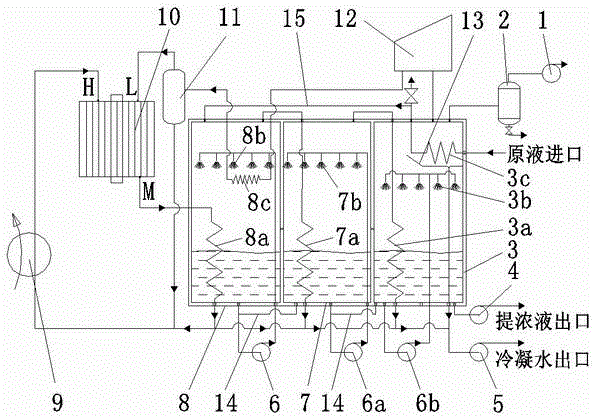

[0024] Example 2 Combined use of steam compressor and phase change gas wave supercharger to complete the recompression of secondary steam.

[0025] figure 2 A continuous evaporation system combining mechanical vapor compression with gas wave vapor recompression is shown. figure 2 and figure 1 The difference is that: the upper space of the final effect evaporator 3 is connected to the phase-change gas wave supercharger 10 through the steam compressor 12, the heat exchanger 8c located in the upper space of the first effect evaporator 8, and the gas-liquid separator 11 in sequence. The low-pressure steam inlet L, the bottom of the gas-liquid separator 11 is connected to the steam boiler 9 and the water inlet of the condensate pump 5 .

[0026] In each effect evaporator, the heat exchange on the evaporating side adopts a forced circulation liquid distributor to complete the liquid distribution. In the co-current and co-current feeding methods, the feed liquid of the front eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com