An annular suction nozzle used for dust collection on the inner surface of a dust cage

An annular suction nozzle and inner surface technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. The effect of complete dust, small ventilation resistance and high air volume utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

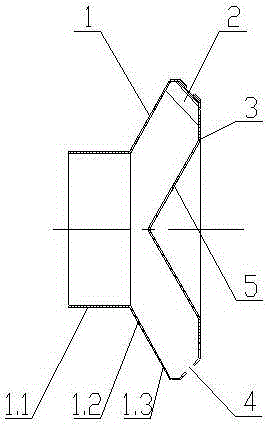

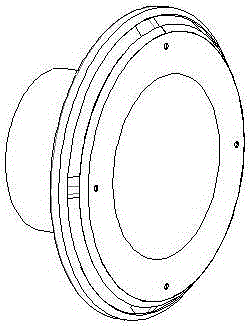

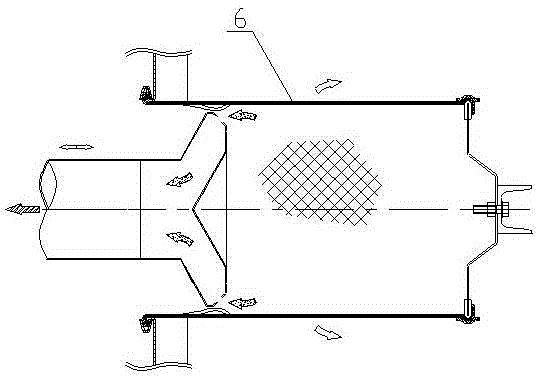

[0027] see Figure 1~Figure 3 , the present invention is an annular suction nozzle applied to the inner surface of the dust cage, which includes a support cylinder 1 and a front plate 3, and the front plate 3 is fixedly arranged on the front side of the support cylinder 1 through a connecting piece. An annular slit suction port 4 is formed between the cylinder 1 and the front disc 3 .

[0028] The support cylinder 1 comprises a horizontal section 1.1 and an inclined section 1.2 forming a flare 1.3.

[0029] The center of the front plate 1 is provided with a diversion cone 5 inwardly, through the function of the diversion cone 5, the ventilation resistance of the suction nozzle itself can be reduced, and the cone angle of the diversion cone 5 is 100-130°.

[0030] The connecting piece is a plurality of spacer blocks 2 uniformly arranged along the circumference, and the spacer block 2 is fixedly arranged on the front side of the inclined section 1.2, and the front plate 3 is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com