No broken hoist

A hoist, no crushing technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problem of crushing, achieve the effect of large lifting capacity, convenient cleaning of materials, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

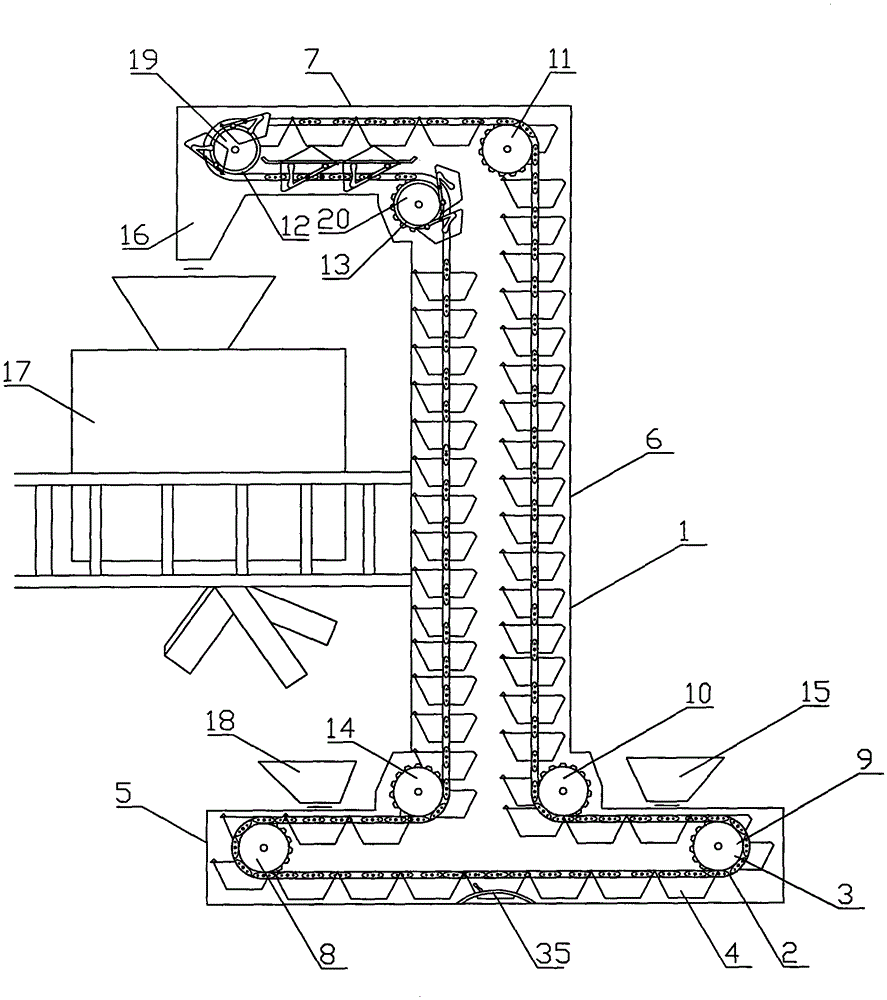

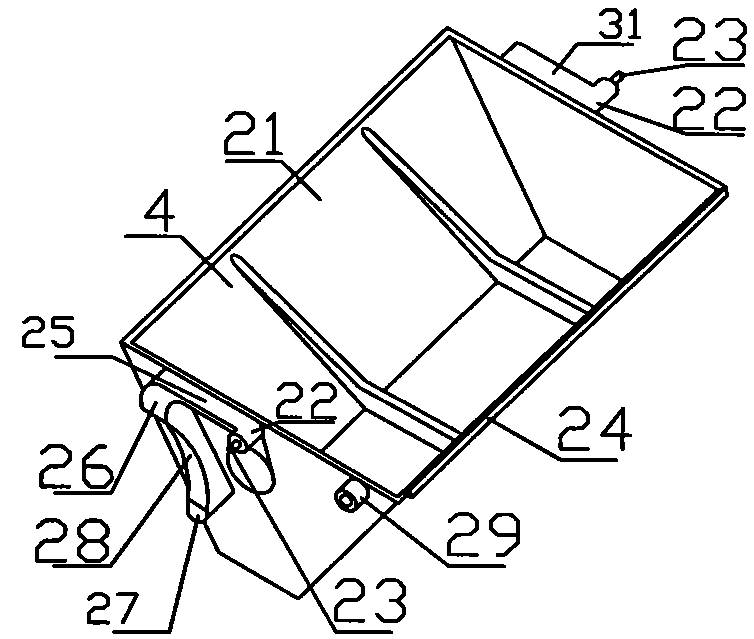

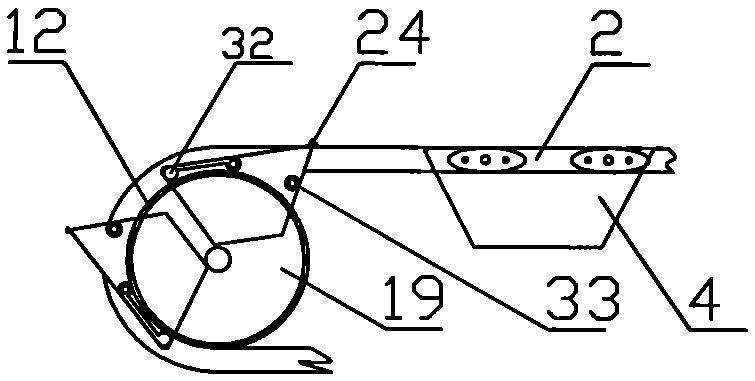

[0028] Embodiment 1: as figure 1 As shown, there is no broken hoist, which includes a hoist housing 1, a traction chain 2, a sprocket set 3 and a hopper 4, and the hoist housing 1 is an inverted J shape, which includes an inline base 5, a column 6 and A discharge chute 7 is provided with a column 6 in the middle of the inline base 5, and a discharge chute 7 is horizontally provided at the top of the column 6; a corresponding sprocket group 3 is provided on the inner wall of the elevator housing 1 both sides, and each A traction chain 2 is meshed on the sprocket set 3 on the side; the sprocket set 3 on each side includes a drive sprocket 8, a driven sprocket 9, a horizontal rotation lifting sprocket 10, a lifting rotation horizontal sprocket 11, and a discharge chain Wheel 12, horizontal turn descending sprocket 13 and descend turn horizontal sprocket 14; Be respectively provided with driving sprocket 8 and driven sprocket 9 at two ends of inline base 5; The bottom is provided...

Embodiment 2

[0030] Embodiment 2: as figure 1 As shown, there is no broken hoist, which includes a hoist housing 1, a traction chain 2, a sprocket group 3, and a hopper 4; wherein, as Figure 6 and Figure 7 As shown, between the guide limit cylinder 29 and the suspension shaft boss 22 on the same side, there is a reinforced sub-plate A-30 integrated with the trapezoidal hopper main body 21, and the reinforced sub-plate A-30 is connected with the guide limit cylinder 29. It has an integrated structure with the suspension shaft boss 22 on the same side; the end face of the unloading rectification disc 20 is in frictional contact with the guide limit cylinder 29, the reinforced flat plate A-25 and the reinforced sub-plate A-30; other structures are the same as in Embodiment 1 same.

Embodiment 3

[0031] Embodiment 3: as Figure 8 As shown, there is no crushing hoist, which includes a hoist housing 1, a traction chain 2, a sprocket group 3, and a hopper 4. The hoist housing 1 is Z-shaped, and it includes an inline base 5, a column 6, a A chute 7 is provided with a column 6 at one end of the inline base 5, and a discharge chute 7 is horizontally provided at the top of the column 6; a corresponding sprocket group 3 is provided on the inner wall of both sides of the elevator housing 1, and on each side A traction chain 2 is meshed on the sprocket set 3; the sprocket set 3 on each side includes a driving sprocket 8, a driven sprocket 9, a horizontal rotation lifting sprocket 10, a lifting rotation horizontal sprocket 11, and a discharge sprocket 12 and horizontally turn down sprocket wheel 13; Be respectively provided with driving sprocket 8 and driven sprocket 9 at two ends of inline base 5; 10. A feed inlet 15 is provided on the upper hoist housing 1 between the driven s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com